Have you ever watched a metal lathe spin? It’s fascinating, isn’t it? A metal lathe is a powerful tool used to shape and cut materials like metal and wood. But did you know that proper lathe workholding is key to making it work? It helps keep the material steady while the lathe cuts it. Without good workholding, your project could go wrong.

One important factor in lathe workholding is torque. Torque is the twist force applied to the workpiece. Imagine trying to open a jar. If you don’t twist it the right way, the lid won’t budge. The same idea applies to metal lathes. If the torque is not just right, you may struggle with your cuts.

In this article, we will dive into the world of lathe workholding. We’ll explore how to achieve the perfect torque and make your projects easier. Get ready to learn some tips that will help you become a metalworking pro!

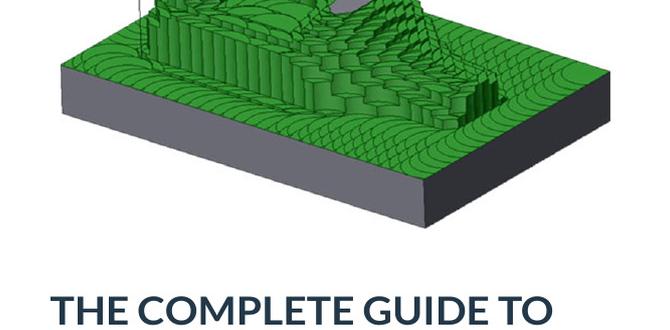

Lathe Workholding: Mastering Metal Lathe Torque Techniques

Lathe Workholding Metal Lathe Torque

Lathe workholding involves gripping metal pieces securely during machining. But did you know that proper torque is crucial for the best results? Using the right torque prevents slippage and ensures safety. Imagine a spinning metal piece flying off! This can happen with incorrect torque. Additionally, various workholding devices like chucks and collets exist for different projects. Understanding torque requirements helps you choose the right tools for success. Keep your projects safe and efficient by mastering these concepts!Choosing the Right Workholding Device for Your Project

Factors to consider when selecting a workholding device. Analysis of material compatibility and part geometry.Picking the right workholding device can feel tougher than herding cats, but it’s crucial for your project’s success. First, think about material compatibility. Not all materials play nice together. For example, softer metals might get squished in a vice meant for the tough stuff. Next, consider the part geometry. Odd shapes need special clamping techniques. A round part won’t sit well in a square hole! Here’s a handy chart to help you out:

| Material | Best Workholding Device |

|---|---|

| Aluminum | Soft Jaws |

| Steel | Tecnomagnete |

| Brass | Pneumatic Vise |

Remember, choose wisely and your projects will run smoother than butter on a hot pancake!

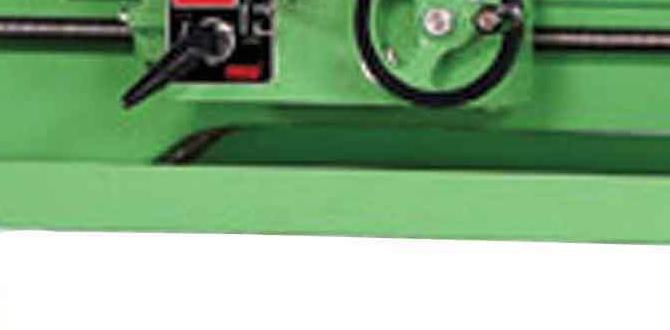

Torque Control in Metal Lathe Workholding

Explanation of torque and its significance in lathe operations. Impact of insufficient torque on workpiece quality and safety.Understanding torque is key in metal lathe workholding. Torque is the twisting force that holds the workpiece securely. If the torque is too low, the workpiece may slip, causing poor cuts and damaging the material. This can lead to unsafe situations for the operator and create waste.

- High torque ensures a solid grip.

- Low torque can cause accidents and poor quality.

- Proper torque keeps the lathe running smoothly.

How does torque affect lathe operations?

Torque affects both safety and quality. Accurate torque leads to fine cuts. Low torque makes the machine less safe, increasing the risk of injury.

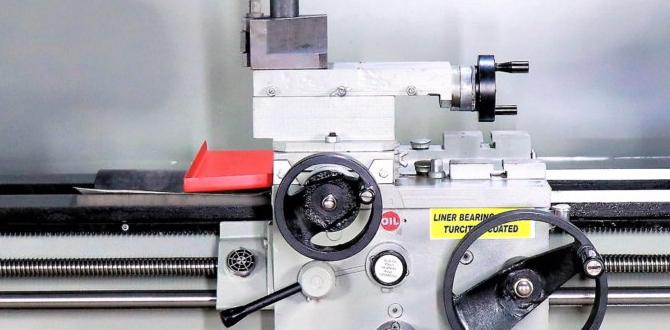

Best Practices for Setting Torque Values

Recommended torque values for common workholding scenarios. Tools and techniques for accurately measuring and setting torque.Setting the right torque value is essential for effective lathe workholding. Here are some tips for common scenarios:

- Chucks: Use 15-20 ft-lbs

- Collets: Aim for 10-15 ft-lbs

- Faceplates: Set to 25-30 ft-lbs

For accurate measurement, try these tools:

- Use a torque wrench for precision.

- Utilize a torque gauge for quick readings.

Regular checks lead to safer operations and better results!

What tools help measure torque values?

Tools like torque wrenches and torque gauges ensure you set the right torque values for safety and effectiveness in metal lathe operations.

Common Challenges and Solutions in Lathe Workholding

Discussing typical issues such as slippage and vibration. Strategies to mitigate common workholding problems.When using lathes, people face challenges like slippage and vibration. These issues can make work hard and unsafe. Solutions to these problems help create better results. Here are some tips to tackle workholding challenges:

- Use proper clamps: Secure your material tightly.

- Check for balance: Ensure that the loaded workpiece is centered.

- Reduce speed: Slower speeds may reduce vibration.

What causes slippage in lathe workholding?

Slippage occurs from inadequate clamping, improper setup, or a dirty surface. These reasons make workpieces move during machining. Proper preparation is key to avoid this problem.

How can I prevent vibration in lathe workholding?

To prevent vibration, check for balance and secure your workpiece firmly. A stable setup leads to better cuts and safer operations. Remember, small changes can make a big difference!

Case Studies: Successful Workholding Applications

Realworld examples of effective workholding strategies. Lessons learned and best practices from various industries.Many companies have found smart ways to hold their work while using a lathe. For example, a car factory improved its parts assembly. They used clamps that perfectly fit each piece. This kept them steady, leading to fewer mistakes and faster production. Another business, a tool maker, improved grip using special jigs. This helped them create precise tools every time. Here are some lessons learned:

- Use custom fixtures for best results.

- Always test your workholding strategy.

- Adjust your setup for different tasks.

These real-life examples show that good workholding can make a big difference in many industries.

What is a successful workholding strategy?

A successful workholding strategy adapts to the specifics of a job. It ensures that materials stay secure during machining for accuracy and safety.

Future Trends in Lathe Workholding Technology

Emerging technologies impacting workholding design (smart manufacturing, automation). Predictions on the evolution of workholding in metal lathe applications.Technology is changing how we hold onto stuff while using lathes. Smart manufacturing and automation are shaking things up. Imagine a lathe that can adjust its grip based on the part being shaped! Sounds cool, right? Predictions say that future workholding designs will use sensors to monitor torque. This means machines will be safer and more efficient. In the future, workholding won’t just hold parts; it will help create them better and faster.

| Technology | Impact on Workholding |

|---|---|

| Smart Manufacturing | Automates grip adjustments for better precision |

| Automation | Reduces human error in the setup process |

Conclusion

In summary, understanding lathe workholding and torque is essential for metalworking. Proper workholding ensures your material stays secure, while accurate torque helps prevent mistakes. You can improve your skills by practicing these techniques. Explore different tools and methods to find what works best for you. Keep learning, and you’ll become more confident using a lathe!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Torque In Metal Lathes:Sure! When you use a lathe, it holds metal pieces in place so you can shape them. To do this, you might use a chuck, which grabs onto the metal tightly. Torque is how much turning force you use when you work. If you use too much torque, you can break the piece, so be careful! Always check that everything is secure before you start working.

Sure! I’m ready for your question. Please go ahead and ask!

What Are The Most Common Workholding Methods Used In Metal Lathes, And How Do They Affect Torque During Machining?The most common ways to hold metal pieces on lathes are chucks and collets. A chuck is a clamp that grips the metal tightly. Collets fit around the metal and hold it securely too. These methods affect torque, which is the twist power needed to turn the metal. A good grip means we can cut better and use less force.

How Do Different Materials (E.G., Aluminum Vs. Steel) Impact The Torque Requirements For Securing Workpieces On A Lathe?Different materials need different forces to hold them tight on a lathe. Aluminum is lighter and easier to hold, so it needs less force, or torque, to secure it. Steel is stronger and heavier, which means you need more torque to keep it in place. When you work with these materials, you should adjust your torque settings accordingly. This helps keep everything safe and working well!

What Precautions Should Be Taken When Tightening Chucks And Fixtures To Ensure Proper Torque And Minimize Workpiece Distortion?When you tighten chucks and fixtures, do it slowly and evenly. Use a torque wrench to check the tightness. This helps avoid too much pressure that can bend the workpiece. Always check that everything is clean before you start. Lastly, make sure the workpiece is balanced to keep it straight and safe.

How Does The Size And Shape Of A Workpiece Influence The Selection Of Workholding Devices And The Corresponding Torque Calculations?The size and shape of a workpiece affect how we hold it in place while working. If it’s big or heavy, we need strong workholding devices, like clamps. A long or odd-shaped piece might need special tools to grip it safely. Torque helps us know how much twist is needed to keep it steady. So, we change our plans based on the workpiece’s size and shape!

What Tools Or Methods Are Available For Measuring Torque When Setting Up Workholding Systems On A Metal Lathe?To measure torque on a metal lathe, you can use a torque wrench. This tool tells you how tight something is by clicking or showing a number. Another way is to use a digital torque meter, which gives you a readout on a screen. You can also use a beam-type torque wrench that moves a needle to show the amount of torque. All these tools help ensure your workholding system is set up correctly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Torque In Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you use a lathe, it holds metal pieces in place so you can shape them. To do this, you might use a chuck, which grabs onto the metal tightly. Torque is how much turning force you use when you work. If you use too much torque, you can break the piece, so be careful! Always check that everything is secure before you start working.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I’m ready for your question. Please go ahead and ask!”}},{“@type”: “Question”,”name”: “What Are The Most Common Workholding Methods Used In Metal Lathes, And How Do They Affect Torque During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The most common ways to hold metal pieces on lathes are chucks and collets. A chuck is a clamp that grips the metal tightly. Collets fit around the metal and hold it securely too. These methods affect torque, which is the twist power needed to turn the metal. A good grip means we can cut better and use less force.”}},{“@type”: “Question”,”name”: “How Do Different Materials (E.G., Aluminum Vs. Steel) Impact The Torque Requirements For Securing Workpieces On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials need different forces to hold them tight on a lathe. Aluminum is lighter and easier to hold, so it needs less force, or torque, to secure it. Steel is stronger and heavier, which means you need more torque to keep it in place. When you work with these materials, you should adjust your torque settings accordingly. This helps keep everything safe and working well!”}},{“@type”: “Question”,”name”: “What Precautions Should Be Taken When Tightening Chucks And Fixtures To Ensure Proper Torque And Minimize Workpiece Distortion?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you tighten chucks and fixtures, do it slowly and evenly. Use a torque wrench to check the tightness. This helps avoid too much pressure that can bend the workpiece. Always check that everything is clean before you start. Lastly, make sure the workpiece is balanced to keep it straight and safe.”}},{“@type”: “Question”,”name”: “How Does The Size And Shape Of A Workpiece Influence The Selection Of Workholding Devices And The Corresponding Torque Calculations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size and shape of a workpiece affect how we hold it in place while working. If it’s big or heavy, we need strong workholding devices, like clamps. A long or odd-shaped piece might need special tools to grip it safely. Torque helps us know how much twist is needed to keep it steady. So, we change our plans based on the workpiece’s size and shape!”}},{“@type”: “Question”,”name”: “What Tools Or Methods Are Available For Measuring Torque When Setting Up Workholding Systems On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure torque on a metal lathe, you can use a torque wrench. This tool tells you how tight something is by clicking or showing a number. Another way is to use a digital torque meter, which gives you a readout on a screen. You can also use a beam-type torque wrench that moves a needle to show the amount of torque. All these tools help ensure your workholding system is set up correctly!”}}]}