Have you ever wondered how metal parts are made with such precision? Lathe workholding is the answer! It’s a key part of using a metal lathe. This special technique helps you hold metal pieces tightly while they spin. Imagine the difference a good workholding setup can make! It can turn a messy project into a smooth one.

If you want to upgrade your metal lathe, you’re in for a treat. Upgrading your setup can make tasks easier and safer. Picture this: you’re working on a project, and you drop a piece of metal. Without proper workholding, you might need to start over. But with the right tools, your work becomes much simpler.

Did you know even small upgrades can lead to big results? Many hobbyists and professionals improve their metal lathes with simple fixes. From clamps to jaws, every detail counts. Upgrading your lathe workholding can boost your skills. Are you ready to unlock the full potential of your metal lathe? Let’s explore what makes a great upgrade!

Effective Lathe Workholding For A Metal Lathe Upgrade

Lathe Workholding Metal Lathe Upgrade

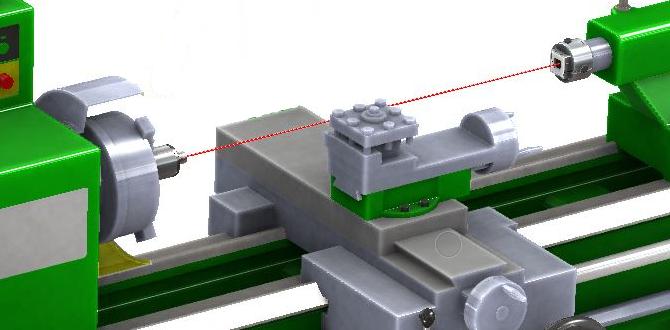

Upgrading your lathe workholding setup can enhance your metalworking projects significantly. A better workholding system means improved accuracy and safety while working. Imagine finishing a project faster and with better results! Newer clamps and fixtures also provide more flexibility for different tasks. Did you know that a simple upgrade could even extend the life of your tools? Explore these upgrades to transform your metal lathe experience and achieve professional results at home.Understanding Workholding Fundamentals

Definition of workholding in metal lathe applications. Importance of effective workholding for precision and safety.Workholding is how we hold materials on a metal lathe. It’s the key to keeping pieces stable and in place while we work. Good workholding leads to precision and safety. If a piece shifts, it can ruin your work or be dangerous. Remember, proper setup is a smart way to get great results.

What is workholding in metal lathe applications?

Workholding refers to the various ways of securing a workpiece during machining. This ensures accurate cuts and shapes, making the final product exactly as planned.

Why is effective workholding important?

- Precision: Secure holding allows for exact measurements.

- Safety: A stable piece reduces the risk of accidents.

Factors to Consider When Upgrading Workholding Equipment

Assessing current and future project needs. Evaluating compatibility with existing lathe systems.Upgrading your workholding equipment is an important step. First, think about your current and future project needs. Will your new setup handle bigger or smaller jobs? Next, check if your new equipment works with your existing lathe system. Compatibility is key. If it doesn’t fit, you might face big problems later.

What should I assess before upgrading my workholding equipment?

Focus on your current projects and possible future tasks. Also, look at how well the new equipment will fit with what you own now.

- Assess project scale

- Check equipment fit

- Identify potential growth

- Research user reviews

Benefits of Upgrading Workholding Systems

Enhanced precision and repeatability. Increased efficiency and reduced cycle times.Upgrading workholding systems can be a game-changer for any machinist! With improved setups, precision becomes your best buddy, making sure parts fit like puzzle pieces. Enhanced precision and repeatability mean fewer mistakes and more smiles. You’ll get more done in less time too. That’s increased efficiency for you! Imagine reducing cycle times and having more hours left for coffee breaks. Or, in the tool shop, more time to look for that sock that disappeared during a tool change!

| Benefit | Explanation |

|---|---|

| Enhanced Precision | Fits parts together perfectly. Less rework! |

| Increased Efficiency | Do tasks faster. More time for fun! |

| Reduced Cycle Times | Complete jobs quicker. Celebrate more! |

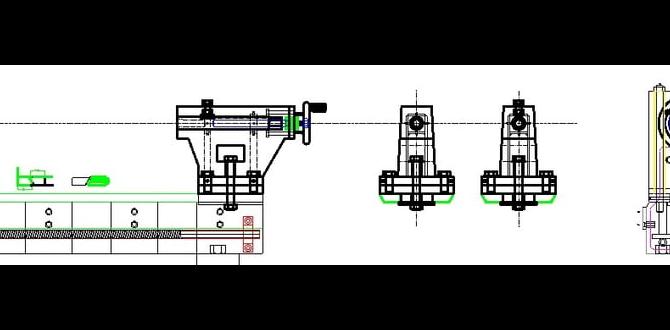

Installation and Setup of New Workholding Systems

Stepbystep guide for installation of upgrades. Tips for proper alignment and calibration.Upgrading your lathe workholding systems can feel overwhelming, but it’s simpler than it seems! Start with these steps:

- First, turn off the lathe and unplug it for safety.

- Remove the old workholding system by loosening the screws.

- Align the new system correctly on the lathe.

- Secure it tightly in place.

- Check that everything is straight and level.

- Plug the lathe back in and test it with a small piece of material.

For good alignment, use a square tool to check corners. Calibrate by adjusting the height until the material spins smoothly. Following these steps ensures your upgrades work well.

How do I install a new workholding system on a lathe?

To install a new workholding system on a lathe, start by removing the old system, align the new one, and secure it tightly. Always double-check for level and make sure it’s straight before testing.

Maintenance Tips for Workholding Devices

Routine inspection and cleaning procedures. Troubleshooting common issues with workholding systems.Keeping your workholding devices in top shape is vital. Regularly check for dirt or wear—think of it like giving your favorite toy a bath! Clean them with a soft cloth and avoid harsh chemicals; no one likes a cranky machine. If your clamps are misbehaving or your chuck struggles to grip, don’t panic. Most issues have simple fixes. Check the screws and bolts and make sure everything is tight. If things still seem off, you might need to re-align or lubricate parts. Happy lathe-ing!

| Common Issues | Troubleshooting Tips |

|---|---|

| Clamp not holding | Check for debris and tighten screws |

| Chuck slipping | Lubricate and realign |

| Vibration during cutting | Balance the workpieces properly |

Real-World Case Studies of Upgraded Workholding

Examples of successful upgrades in various industries. Lessons learned and best practices from implementation.Upgrades to workholding can create powerful changes in various industries. For example, a car manufacturer improved its production speed by 30% after adopting new clamping systems. This helped them save time and boost profits! Another company making airplane parts found that using advanced fixtures reduced mistakes by 25%. They learned that investing in the right tools pays off. Remember, success comes from testing new techniques and sharing best practices. After all, even the best lathe can’t fix bad habits!

| Industry | Upgrade Example | Results |

|---|---|---|

| Automotive | New clamping systems | 30% increase in speed |

| Aerospace | Advanced fixtures | 25% reduction in mistakes |

Future Trends in Workholding Technology

Exploration of automation and smart technologies in workholding. Predictions for the next generation of metal lathe upgrades.The future looks bright for workholding technology, blending automation with smart solutions. Imagine a metal lathe that can think for itself. Exciting, right? These upgrades might soon include sensors that adjust clamps automatically, making setup a breeze! Experts predict that the next generation will also feature AI-driven controls to enhance precision. Fun fact: By 2030, 80% of manufacturing will likely use some form of smart tech. Just think what that could mean for our hobby lathes!

| Upgrade | Benefit |

|---|---|

| Automated Clamps | Faster setup times |

| AI Sensors | Increased accuracy |

| Remote Monitoring | Less downtime |

Conclusion

Upgrading your metal lathe workholding can boost your projects’ quality and efficiency. Stronger clamps and better chucks hold materials securely, preventing slips. By investing in quality accessories, you can achieve more precise results. We encourage you to explore upgrade options that fit your needs. Ready to enhance your lathe experience? Dive into more resources and start leveling up your skills!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding And Upgrading A Metal Lathe:Sure! When you use a metal lathe, you need to hold your pieces steady. This is called workholding. You can upgrade your lathe by adding better tools or clamps. This helps you make smoother and more precise cuts. Always remember to check your equipment and keep it clean!

Sure! Please provide the question you would like me to answer.

What Are The Most Effective Workholding Methods For Increasing Precision And Stability In Metal Lathe Operations?To hold metal pieces steady in a lathe, we can use a few methods. A strong choice is a chuck, which grabs the metal firmly. A vise can also hold shapes tightly as we work on them. Using clamps helps keep everything from moving. These tools make our work more accurate and stable.

How Can Upgrading To A Hydraulic Chuck Improve Workholding Performance On A Metal Lathe?Upgrading to a hydraulic chuck can make holding metal pieces tighter and more secure. This means your work won’t slip while you are cutting it. A hydraulic chuck can also adjust better to different sizes of metal. This helps you work faster and make better products. Overall, it makes using a metal lathe easier and more reliable.

What Factors Should Be Considered When Selecting New Workholding Accessories For An Older Metal Lathe Model?When choosing new workholding accessories for an older metal lathe, we need to think about a few important things. First, check the size and shape of the lathe. It’s also good to make sure the new parts fit well with what you already have. You should think about how often you will use them and if they can hold your projects safely. Finally, look for good quality, so they last a long time!

How Do Different Jaw Configurations On Lathe Chucks Affect The Clamping Of Varying Workpiece Geometries?Different jaw configurations on lathe chucks help hold different shapes of materials tightly. For example, three-jaw chucks are great for round pieces, while four-jaw chucks can hold square or odd-shaped items better. You can adjust the jaws to fit the shape, which keeps the workpiece stable while you work on it. This lets you make safer, smoother cuts.

What Are The Advantages And Disadvantages Of Using A Collet System Versus A Standard Chuck For Workholding In A Metal Lathe?Using a collet system makes it easier to hold small pieces tightly. This means less chance of slipping, which helps us make more accurate cuts. However, collets can be more expensive than standard chucks. Standard chucks are very easy to use and cheaper, but they might not hold smaller pieces as well. So, you should pick the right one based on what you’re working on.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding And Upgrading A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you use a metal lathe, you need to hold your pieces steady. This is called workholding. You can upgrade your lathe by adding better tools or clamps. This helps you make smoother and more precise cuts. Always remember to check your equipment and keep it clean!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Effective Workholding Methods For Increasing Precision And Stability In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To hold metal pieces steady in a lathe, we can use a few methods. A strong choice is a chuck, which grabs the metal firmly. A vise can also hold shapes tightly as we work on them. Using clamps helps keep everything from moving. These tools make our work more accurate and stable.”}},{“@type”: “Question”,”name”: “How Can Upgrading To A Hydraulic Chuck Improve Workholding Performance On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading to a hydraulic chuck can make holding metal pieces tighter and more secure. This means your work won’t slip while you are cutting it. A hydraulic chuck can also adjust better to different sizes of metal. This helps you work faster and make better products. Overall, it makes using a metal lathe easier and more reliable.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting New Workholding Accessories For An Older Metal Lathe Model? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing new workholding accessories for an older metal lathe, we need to think about a few important things. First, check the size and shape of the lathe. It’s also good to make sure the new parts fit well with what you already have. You should think about how often you will use them and if they can hold your projects safely. Finally, look for good quality, so they last a long time!”}},{“@type”: “Question”,”name”: “How Do Different Jaw Configurations On Lathe Chucks Affect The Clamping Of Varying Workpiece Geometries? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different jaw configurations on lathe chucks help hold different shapes of materials tightly. For example, three-jaw chucks are great for round pieces, while four-jaw chucks can hold square or odd-shaped items better. You can adjust the jaws to fit the shape, which keeps the workpiece stable while you work on it. This lets you make safer, smoother cuts.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Collet System Versus A Standard Chuck For Workholding In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system makes it easier to hold small pieces tightly. This means less chance of slipping, which helps us make more accurate cuts. However, collets can be more expensive than standard chucks. Standard chucks are very easy to use and cheaper, but they might not hold smaller pieces as well. So, you should pick the right one based on what you’re working on.”}}]}