Have you ever wondered how craftsmen create stunning wooden bowls or precise metal parts? They often rely on special tools called lathes. But did you know that there are two main types of lathes: metal lathes and wood lathes? Each type has its unique way of working with materials.

Think of a metal lathe as a giant spinning machine that shapes metal into shiny parts. In contrast, a wood lathe spins wood, allowing artisans to carve beautiful designs. Imagine watching a piece of wood transform into a smooth candle holder right before your eyes!

Many people ask, “What’s the difference between these two?” It’s a great question. Understanding lathe workholding can help you choose the right lathe for your projects. Whether you want to make a sturdy metal tool or a delicate wooden vase, knowing your lathe type matters!

In this article, we will explore the exciting world of lathe workholding, comparing metal lathes and wood lathes. Get ready to discover which lathe might be best for you!

Lathe Workholding: Metal Lathe Vs Wood Lathe Explained

Lathe Workholding: Metal Lathe vs. Wood Lathe

Lathe workholding involves how materials are secured for shaping. Metal lathes often use a chuck or faceplate, while wood lathes may utilize a spindle or wooden jaws. Did you know that creating a perfect wooden bowl can hinge on the right lathe? Metal lathes are great for precision, making them excellent for parts like gears. Meanwhile, wood lathes shine in artistic projects like furniture. Understanding the differences helps you choose the right tool for your crafting needs!Understanding Lathe Workholding

Definition of lathe workholding. Importance of proper workholding for accuracy and safety.Lathe workholding is how you secure your material on a lathe. Proper workholding is key for accurate cuts and a safe workspace. If the material isn’t held tightly, it can slip and cause errors or even injuries. Using the right clamps and fixtures can make a big difference. Here are some important points:

- Accuracy: It helps you make precise shapes.

- Safety: Keeps your material stable while you work.

- Efficiency: Lets you focus on your project without worries.

Why is proper workholding important?

Proper workholding ensures accuracy and safety while using a lathe. It prevents accidents and helps you create better results.

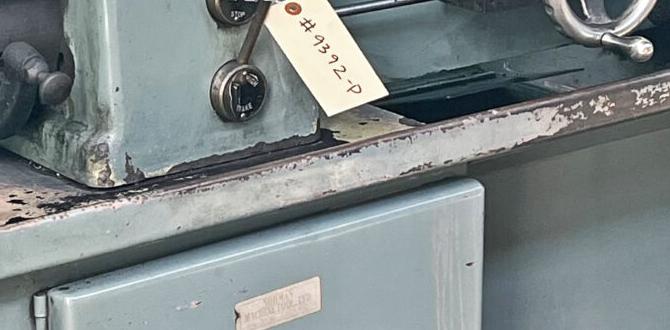

Workholding Methods in Metal Lathes

Types of chucks: threejaw, fourjaw, and collet chucks. Additional workholding devices: faceplates, mandrels, and fixtures.In metal lathes, the way you hold materials is very important. Different chucks help you grip the metal securely. The three main types are:

- Three-jaw chucks: Great for quick setups. They hold round pieces well.

- Four-jaw chucks: Perfect for odd shapes. You can adjust each jaw separately.

- Collet chucks: Best for small parts. They provide a tight grip.

Other useful tools include:

- Faceplates: Used for larger pieces.

- Mandrels: Help hold items while turning.

- Fixtures: Keep things stable during work.

These methods help make metal lathes more effective and precise.

What are the main workholding devices for metal lathes?

The main workholding devices are chucks, faceplates, mandrels, and fixtures. Each serves a unique purpose for different shapes and sizes of materials.

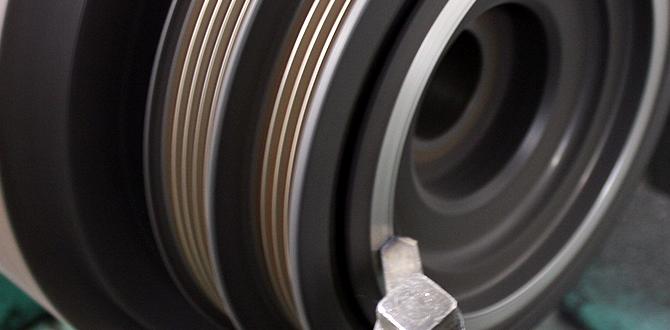

Workholding Methods in Wood Lathes

Types of chucks: bowl chucks and spindle chucks. Alternative methods: spur centers and live centers, faceplates.In wood lathes, workholding methods are key to shaping beautiful pieces. Two popular types of chucks are bowl chucks and spindle chucks. Bowl chucks grip the wood from the outside, perfect for making bowls that look like they jumped out of a fairy tale. Spindle chucks, on the other hand, hold the wood from the inside, ideal for items like spindles and pens.

Other methods include spur centers and live centers. Spur centers dig into the wood, while live centers spin with it—like they’re dancing! Faceplates are another option, allowing you to screw wood directly onto the plate. This method is great for bigger projects.

| Workholding Method | Description |

|---|---|

| Bowl Chucks | Good for gripping the outside of the wood. |

| Spindle Chucks | Holds wood from the inside. |

| Spur Centers | Dig into the wood for a strong hold. |

| Live Centers | Spin with the wood for smooth turning. |

| Faceplates | Screw wood onto a plate for bigger projects. |

With these tools, wood lathes make magic happen! You can create whatever your heart desires. Just remember, the right workholding leads to amazing creations—just like Santa’s workshop, without the elves!

Comparative Analysis: Metal vs. Wood Lathe Workholding

Differences in workpiece preparation and setup. Impact on machining precision and finish quality.Setting up a workpiece for metal and wood lathes can feel like choosing between pizza and ice cream—both delicious, but totally different! Metal lathes need snug workholding for precision. Every tiny movement can affect the final product! They often use chucks or collets for a tight grip. Wood lathes, on the other hand, enjoy some wiggle room with faceplates and centers. They’re forgiving, making each project a fun adventure. In the end, machine precision and finish quality depend on how well you prepare your workpiece!

| Feature | Metal Lathe | Wood Lathe |

|---|---|---|

| Workpiece Preparation | Needs tight workholding | Can be looser |

| Setup Time | More time-consuming | Quicker setup |

| Machining Precision | High precision | Good finish, but less precision |

Choosing the Right Workholding for Your Project

Factors to consider: material type, project complexity, and desired finish. Recommendations for beginners vs. advanced users.Choosing the right workholding is important for your project. You must think about a few key factors:

- Material type: Different materials need different techniques.

- Project complexity: Simple projects need basic setups. Complex ones may require advanced tools.

- Desired finish: Some finishes need extra care for a perfect look.

For beginners, use simple clamps or chucks. Advanced users can try more precise methods like collets. Remember, the right choice can make your work easier and your results better!

What should beginners choose for workholding?

Beginners should start with simple clamps or chucks. They are easy to use and effective for basic projects.

Key points for beginners:

- Simple tools are less confusing.

- Focus on one project at a time.

- Practice will make you better.

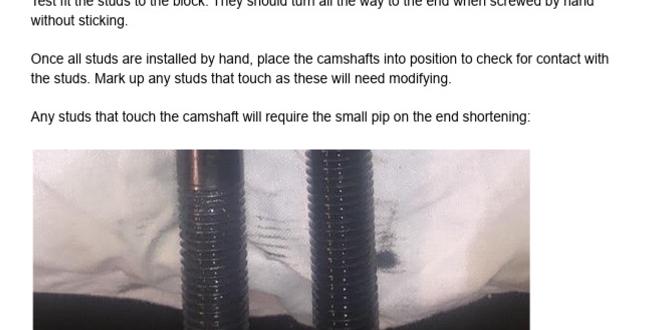

Common Challenges in Lathe Workholding

Issues with vibration and runout. Adjustments for different materials and shapes.Lathe workholding can be tricky at times. One common issue is vibration. It can cause poor cuts and make your project look messy. Runout is another problem. This means the tool or workpiece does not spin perfectly in place. Adjustments are necessary for different materials. Some are soft, while others are hard. Each shape needs a unique way to hold it tight.

- Vibrations can lead to mistakes.

- Runout affects precision.

- Soft materials need less grip.

- Hard materials need strong support.

What causes vibration in lathe workholding?

Vibration often comes from parts that are unbalanced or poorly supported.Why is runout important in lathe workholding?

Runout affects the accuracy of cuts and the overall quality of your piece.Best Practices for Optimizing Lathe Workholding

Techniques for securing workpieces effectively. Maintenance of workholding equipment for longevity and efficiency.Effective workholding is key to great lathe work. Secure your pieces well for accurate cuts. Use sturdy clamps and chucks to hold your material tightly. Regularly check and maintain your tools. Clean them after use and inspect for wear. A well-kept tool lasts longer and works better.

How can I secure my workpieces effectively?

Use high-quality clamps, chucks, and vises. Check the fit and adjust as needed for stability.

Maintenance tips for workholding equipment:

- Clean tools after every use.

- Inspect for damage regularly.

- Lubricate moving parts to prevent rust.

- Store tools in a dry, safe place.

Innovations in Lathe Workholding Technology

Recent advancements in chuck design and automation. Future trends in lathe workholding solutions.New tools and machines are changing how we hold materials in lathes. Recent chuck designs let us secure items faster and more securely. This helps reduce errors. Automation is taking over some of the work, making it easier and safer.

Looking ahead, we can expect even smarter solutions. Future lathes might have sensors to check if everything is in place. This means less guesswork and more accuracy. New technologies will make lathe workholding even better.

- Improved chuck designs boost efficiency.

- Automation minimizes human error.

- Sensors will enhance accuracy in the future.

What are the benefits of new workholding methods?

New methods are safer and faster. They reduce mistakes, making work easier. These advances help both metal and wood lathe users. They save time and make results better.

Conclusion

In summary, metal lathes and wood lathes serve different purposes. Metal lathes shape hard materials like metal, while wood lathes focus on softer woods. You should consider your projects before choosing. If you prefer woodworking, start with a wood lathe. For metalworking, a metal lathe is best. Explore more about both types to see what fits your needs!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Comparing Metal Lathes And Wood Lathes:Sure! Let’s think about lathes, which are machines that spin things to help shape them. Metal lathes are good for making strong, detailed parts from metal. We use wood lathes to create smooth, curved shapes from wood. Both types hold their material in place, but they have different tools and settings. It’s like using different toys for different games!

Sure! Please provide the question you would like me to answer.

What Are The Key Differences In Workholding Methods Between Metal Lathes And Wood Lathes?Metal lathes and wood lathes hold their materials in different ways. On metal lathes, we usually use clamps or chucks to grip metal pieces tightly. For wood lathes, we often use centers and faceplates, which help keep the wood stable while it spins. Metal needs a stronger grip because it is harder, while wood is easier to hold in place. This makes each type of lathe better for its specific material.

How Do The Materials Typically Used In Metal Lathes Affect The Choice Of Workholding Tools?Metal lathes are made from strong materials like steel and cast iron. These materials can be heavy and sturdy. When choosing workholding tools, we need something that can hold these heavy pieces firmly. If the tools aren’t strong enough, they might let the metal move, which can mess up our work. So, we pick tools that match the strength of the materials we use.

What Are The Advantages Of Using A Chuck System Versus A Faceplate In Wood Lathe Workholding?Using a chuck system is often better than a faceplate. A chuck holds your wood tightly from all sides. This means your wood stays steady while you work. With a faceplate, wood can wiggle more, making it harder to shape. Plus, a chuck lets you change pieces faster and easier!

How Can The Vibrations Produced During Lathe Work Impact The Effectiveness Of Workholding In Metal Versus Wood Lathes?Vibrations from a lathe can make it hard to hold the material tightly. In metal lathes, these vibrations can create larger problems. Metal is heavy and stiff, so even small movements can cause mistakes. Wood lathes shake more but are generally easier to handle. You need to make sure the material is held well to get a clean cut.

What Safety Considerations Should Be Taken Into Account For Workholding Setups In Metal Lathes Compared To Wood Lathes?When using metal lathes, we should be careful about sharp tools and heavy parts. Always wear safety glasses to protect your eyes. Metal can create flying chips, so keep your hands and face safe. Wood may not be as heavy, but it can still break and fly. Always check your setup twice to make sure everything is tight and secure.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Comparing Metal Lathes And Wood Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Let’s think about lathes, which are machines that spin things to help shape them. Metal lathes are good for making strong, detailed parts from metal. We use wood lathes to create smooth, curved shapes from wood. Both types hold their material in place, but they have different tools and settings. It’s like using different toys for different games!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Differences In Workholding Methods Between Metal Lathes And Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes and wood lathes hold their materials in different ways. On metal lathes, we usually use clamps or chucks to grip metal pieces tightly. For wood lathes, we often use centers and faceplates, which help keep the wood stable while it spins. Metal needs a stronger grip because it is harder, while wood is easier to hold in place. This makes each type of lathe better for its specific material.”}},{“@type”: “Question”,”name”: “How Do The Materials Typically Used In Metal Lathes Affect The Choice Of Workholding Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes are made from strong materials like steel and cast iron. These materials can be heavy and sturdy. When choosing workholding tools, we need something that can hold these heavy pieces firmly. If the tools aren’t strong enough, they might let the metal move, which can mess up our work. So, we pick tools that match the strength of the materials we use.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Chuck System Versus A Faceplate In Wood Lathe Workholding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a chuck system is often better than a faceplate. A chuck holds your wood tightly from all sides. This means your wood stays steady while you work. With a faceplate, wood can wiggle more, making it harder to shape. Plus, a chuck lets you change pieces faster and easier!”}},{“@type”: “Question”,”name”: “How Can The Vibrations Produced During Lathe Work Impact The Effectiveness Of Workholding In Metal Versus Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Vibrations from a lathe can make it hard to hold the material tightly. In metal lathes, these vibrations can create larger problems. Metal is heavy and stiff, so even small movements can cause mistakes. Wood lathes shake more but are generally easier to handle. You need to make sure the material is held well to get a clean cut.”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account For Workholding Setups In Metal Lathes Compared To Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using metal lathes, we should be careful about sharp tools and heavy parts. Always wear safety glasses to protect your eyes. Metal can create flying chips, so keep your hands and face safe. Wood may not be as heavy, but it can still break and fly. Always check your setup twice to make sure everything is tight and secure.”}}]}