Have you ever thought about how a metal lathe can transform raw materials into amazing creations? Setting up a lathe workshop might seem tricky at first, but it’s an adventure worth exploring. Imagine having a sturdy metal lathe bed as the centerpiece of your new workshop. It can turn simple metal blocks into intricate parts with just a few turns.

Did you know that many skilled craftsmen started with just a basic lathe setup? They learned and grew their skills, creating amazing projects along the way. What if you could be the next one? By properly setting up your lathe workshop, you can unlock new possibilities and unleash your creativity.

Whether you’re a hobbyist or an aspiring professional, understanding how to arrange your metal lathe is key. It’s not just about the machine; it’s about the whole space. So, are you ready to dive into the exciting world of lathe workshop setup? Let’s explore how to create a perfect space for your metal lathe!

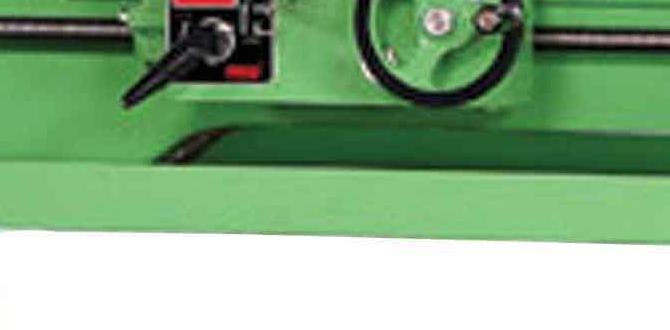

Lathe Workshop Setup: Optimizing Your Metal Lathe Bed

Lathe Workshop Setup: Metal Lathe Bed

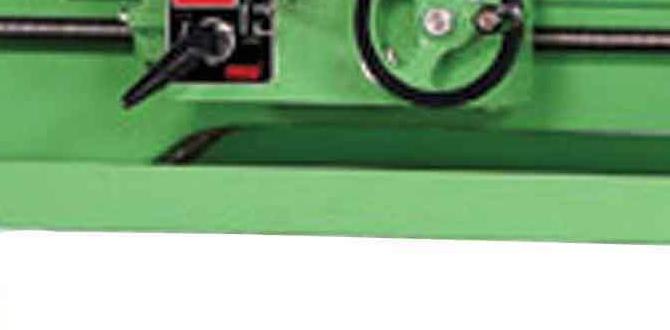

Setting up a metal lathe bed is key for efficient machining. A stable bed ensures precision and smooth operation. Did you know a level lathe reduces wear on moving parts? First, choose a sturdy surface. Secure the lathe to prevent any movement. Align it carefully for best accuracy. Proper tools and workspace organization enhance productivity. A tidy workshop also helps you find tools easily. Excited to create with your lathe? A solid setup leads to amazing results!Understanding the Basics of a Metal Lathe

Definition and function of a metal lathe. Types of metal lathes and their applications.A metal lathe is an amazing machine that shapes and cuts metal. Imagine it like a magic wand that turns a block of metal into something useful, like a tool or a part for a car. There are different types of metal lathes—some are small and perfect for home projects, while others are big enough for factories. Applications vary from making screws to crafting fancy art pieces, showing how versatile these machines are.

| Type of Metal Lathe | Application |

|---|---|

| Mini Lathe | Hobby projects |

| Engine Lathe | Precision parts |

| CNC Lathe | Automated manufacturing |

So, whether you’re crafting a toy or building a real-life robot, a metal lathe can help you turn your metal dreams into reality!

Choosing the Right Location for Your Lathe Workshop

Key factors for selecting a workspace. Considerations for lighting, ventilation, and accessibility.Choosing the right spot for a lathe workshop can feel like searching for a needle in a haystack. First, make sure there’s plenty of light. You need to see what you’re doing, unless you enjoy surprises! Good ventilation is a must, so fresh air keeps you awake and your workspace smell-free. Accessibility is key, too. You want to slide around smoothly, not play a game of “how many steps can I take without tripping?”

| Factor | Importance |

|---|---|

| Lighting | Helps you see your work clearly |

| Ventilation | Prevents bad smells and keeps you fresh |

| Accessibility | Makes moving around easy |

So, pick your location wisely. Your lathe will love its new home, and so will you!

Essential Tools and Equipment for Lathe Setup

List of essential tools for operating a metal lathe. Additional safety equipment and technology to enhance efficiency.Setting up a lathe workshop requires specific tools to work smoothly. Here are some essential tools you’ll need:

- Metal lathe

- Cutting tools (like chisels)

- Calipers for measuring

- Wrenches to adjust parts

- Workbench for stability

- Safety goggles and gloves

- Toolbox to organize

Having good safety equipment helps prevent accidents. Proper lighting can also improve efficiency. Always keep your workspace neat!

What tools do I need to operate a metal lathe?

You need essential tools like a metal lathe, cutting tools, and safety gear.

Preparing the Lathe Bed: Materials and Maintenance

Common materials used for lathe beds. Maintenance tips to ensure longevity and accuracy.Lathe beds can be made from several strong materials. The most common is cast iron; it’s heavy and stays steady during work. Steel is another option, known for its durability. Most lathes use precision ground surfaces to keep everything aligned. To keep your lathe bed in top shape, clean it regularly and avoid rust. Lubrication is key too! A little oil goes a long way. Remember, a well-cared-for lathe bed is like a happy dog—always ready to work!

| Material | Benefits |

|---|---|

| Cast Iron | Weight and stability |

| Steel | Durability |

| Aluminum | Lightweight and easy to move |

Setting Up Your Metal Lathe: Step-by-Step Guide

Detailed instructions on lathe installation. Importance of leveling and securing the lathe properly.Setting up a metal lathe can be as exciting as opening a surprise gift. First, find a strong, flat surface for your lathe. Level it carefully to ensure smooth operation. Use a trusty level tool; it’s like a magic wand for precision! Next, secure the lathe with bolts. This prevents it from doing the cha-cha while you work. Remember, a wobbling lathe is like a dance partner who can’t keep time—frustrating! Follow these steps, and your lathe will be ready for action.

| Steps | Tips |

|---|---|

| 1. Choose a sturdy surface | Make sure it’s flat and stable! |

| 2. Level the lathe | Use a level tool for accuracy. |

| 3. Secure with bolts | This keeps it steady. |

Workspace Organization and Efficiency

Tips for arranging tools and equipment for optimal workflow. Importance of storage solutions and clutter management.Good organization can make a big difference in your workshop. Arrange tools by size or use. This helps you find what you need quickly. Use storage boxes to keep everything tidy. Bags, racks, and shelves save space. Less clutter means a safer and smoother workflow. Remember to clean up after each project. An organized space also helps you think better and be more creative! Keep your workspace neat and watch your efficiency soar.

How can I arrange my tools for better workflow?

Arrange tools based on frequency of use. Place the most used tools within easy reach. Group similar tools together, like cutting or measuring tools. Use labels for quick identification. Make sure your workspace can adapt if your needs change!

Tips for Tool Arrangement:

- Store heavy tools on lower shelves.

- Use wall space for hanging tools.

- Keep a clean area for projects.

Safety Protocols in the Lathe Workshop

Essential safety practices for operating a metal lathe. Common hazards and how to mitigate them.Using a metal lathe can be a blast, but safety is key! First, keep your workspace tidy. A clean shop is a happy shop, or so they say! Always wear protective gear like goggles and gloves to protect those peepers and fingers. Remember, tools can be sneaky! Common hazards include flying shavings and sharp edges, so mitigate risks by staying focused. If you’re ever unsure, just ask for help—better safe than sorry. Here’s a quick safety checklist:

| Safety Practice | Description |

|---|---|

| Goggles | Protect your eyes from flying debris. |

| Gloves | Keep your hands safe from sharp parts. |

| Clean Work Area | A void tripping hazards and clutter. |

| Stay Focused | Avoid distractions while operating the lathe. |

Improving Skills: Techniques for Effective Lathe Use

Recommended techniques and practices for beginners. Resources for further skill development and learning.To improve your skills in using a lathe, practice is key. Start with simple projects to build your confidence. Focus on basic techniques like measuring, cutting, and sanding. Here are some beginner-friendly tips:

- Use sharp tools for clean cuts.

- Keep your workspace organized.

- Watch tutorial videos for guidance.

- Keep safety gear handy.

For further learning, explore books and online courses. They offer great tips and tricks. You can even join a local workshop to meet other metal lathe enthusiasts. This community can boost your skill set and inspire new ideas.

What resources can help beginners learn lathe techniques?

Beginning lathe users can benefit from online tutorials, books, and local workshops. These resources provide hands-on experience and deeper understanding, helping you become a skilled lathe worker.

Common Challenges in Lathe Workshop Setup

Typical problems faced during setup and operation. Solutions and troubleshooting tips for common issues.Setting up a lathe workshop can feel like a never-ending puzzle. One common problem is getting the lathe level. If it’s not, your work will be wobbly, and nobody wants a wobbly project! Ensure you check the lathe bed with a level tool. Another challenge is maintaining proper alignment. If your tools aren’t straight, you could end up creating a masterpiece that resembles modern art! Always double-check your setup. Plus, don’t forget about those pesky power issues. Keeping a backup generator can save you from sudden power loss disasters!

| Common Issue | Solution |

|---|---|

| Unlevel lathe bed | Use a leveling tool to adjust it. |

| Poor alignment | Regularly check tool placement. |

| Power failures | Consider a backup generator. |

Conclusion

Setting up a lathe workshop with a solid metal lathe bed is crucial. It provides stability and precision for your projects. Remember to organize your tools for easy access. Safety is also important, so always wear protective gear. You can explore more about lathe setups online or in books. Ready to start your journey in machining? Let’s get to work!FAQs

What Are The Essential Considerations For Selecting The Right Location For A Metal Lathe Bed In A Workshop Setup?When choosing a spot for your metal lathe bed, think about space and safety. You need enough room to move around easily. Make sure the surface is strong and level so the lathe doesn’t shake. Good lighting helps you see what you’re doing better. Finally, keep it away from distractions to focus on your work.

How Do You Properly Level And Secure A Metal Lathe Bed To Ensure Precision During Machining Operations?To level and secure a metal lathe bed, first, find a flat surface. Place a level on the lathe bed to check if it’s even. Adjust the feet or base until the level shows it is straight. Use bolts to secure the lathe to the floor or workbench. This keeps it steady while you work.

What Types Of Surfaces Or Materials Should Be Used To Support The Metal Lathe Bed For Optimal Performance?To support a metal lathe bed well, you should use a strong and flat surface. A sturdy table or workbench made of wood or metal works great. Make sure it’s level so the lathe doesn’t wobble. Using rubber pads can help reduce vibrations. This way, your lathe will run smoothly and safely.

How Can You Optimize The Workspace Layout Around The Metal Lathe Bed To Enhance Efficiency And Safety?To make your workspace around the metal lathe safe and efficient, you can start by keeping it tidy. Store tools and parts close by, so you don’t have to search for them. Make sure there’s enough space to walk around without tripping. Also, keep danger signs visible and use safety gear like goggles. This way, we can work better and stay safe!

What Maintenance Practices Are Recommended To Keep The Metal Lathe Bed In Good Condition Over Time?To keep the metal lathe bed in good shape, you should clean it regularly. Use a soft cloth to wipe off dust and oil. Apply a little lubrication to moving parts to prevent rust. Check for any damage often, so you can fix it quickly. Remember, taking care of your lathe helps it last longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Considerations For Selecting The Right Location For A Metal Lathe Bed In A Workshop Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a spot for your metal lathe bed, think about space and safety. You need enough room to move around easily. Make sure the surface is strong and level so the lathe doesn’t shake. Good lighting helps you see what you’re doing better. Finally, keep it away from distractions to focus on your work.”}},{“@type”: “Question”,”name”: “How Do You Properly Level And Secure A Metal Lathe Bed To Ensure Precision During Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level and secure a metal lathe bed, first, find a flat surface. Place a level on the lathe bed to check if it’s even. Adjust the feet or base until the level shows it is straight. Use bolts to secure the lathe to the floor or workbench. This keeps it steady while you work.”}},{“@type”: “Question”,”name”: “What Types Of Surfaces Or Materials Should Be Used To Support The Metal Lathe Bed For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To support a metal lathe bed well, you should use a strong and flat surface. A sturdy table or workbench made of wood or metal works great. Make sure it’s level so the lathe doesn’t wobble. Using rubber pads can help reduce vibrations. This way, your lathe will run smoothly and safely.”}},{“@type”: “Question”,”name”: “How Can You Optimize The Workspace Layout Around The Metal Lathe Bed To Enhance Efficiency And Safety? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your workspace around the metal lathe safe and efficient, you can start by keeping it tidy. Store tools and parts close by, so you don’t have to search for them. Make sure there’s enough space to walk around without tripping. Also, keep danger signs visible and use safety gear like goggles. This way, we can work better and stay safe!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended To Keep The Metal Lathe Bed In Good Condition Over Time? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the metal lathe bed in good shape, you should clean it regularly. Use a soft cloth to wipe off dust and oil. Apply a little lubrication to moving parts to prevent rust. Check for any damage often, so you can fix it quickly. Remember, taking care of your lathe helps it last longer!”}}]}