Have you ever walked into a workshop and felt amazed by the tools there? A lathe workshop can be one of the most exciting places. With a metal lathe, you can create amazing things from simple blocks of metal. But how do you set it up? The right setup makes a huge difference.

Choosing the best metal lathe brands can be tricky. Some machines are more reliable than others. How do you know which one to pick? Imagine making your first part on a lathe, seeing your idea come to life. It’s thrilling!

In this article, we’ll explore how to set up your lathe workshop and share some popular metal lathe brands. You’ll learn tips to create a space that inspires creativity and productivity. Are you ready to dive into the world of metalworking? Let’s get started!

Effective Lathe Workshop Setup: Top Metal Lathe Brands

Exploring Lathe Workshop Setup and Brands

Setting up a lathe workshop is exciting for metalworking enthusiasts. First, choose the right space with ample room for tools and materials. Selecting the best metal lathe brands is crucial. Popular choices include Grizzly, Jet, and Erie tools. Each brand offers unique features. Want a smooth finish or high precision? Your choice matters. Did you know that even beginners can create impressive projects with the right setup? Dive in and explore the world of lathes!Understanding Lathe Workshop Setup

Importance of a wellorganized workspace. Essential tools and materials needed for lathe work.A tidy workspace is key for safe and effective lathe work. With everything in its place, you can focus better and avoid accidents. Make sure to gather essential tools like:

- Metal lathe

- Cutting tools

- Measuring equipment

- Chucks and collets

- Safety gear

Having these tools ready helps you create amazing projects and keeps your workshop running smoothly. Remember, a well-organized area is a happy area!

Why is a well-organized workspace important?

A well-organized workspace boosts safety, focus, and efficiency. It allows you to locate tools quickly and reduces the risk of accidents.

What tools do I need for lathe work?

Essential tools include cutting tools, measuring equipment, chucks, and safety gear. These help you work effectively and safely.

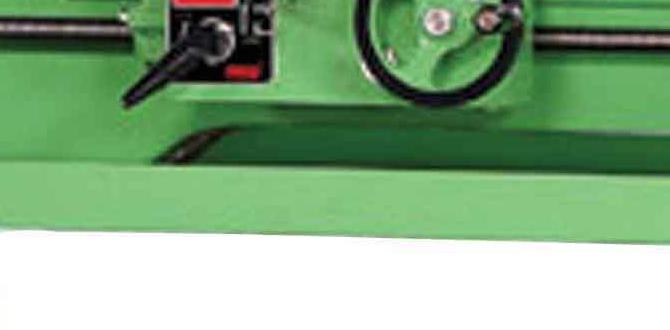

Types of Metal Lathes

Comparison of various metal lathe types (bench lathes, floor lathes, CNC lathes). Application differences for each type of lathe.Metal lathes come in various types, each with its own special magic. First, we have bench lathes, tiny but mighty. They sit on a bench, perfect for small projects and beginners. Next are floor lathes, which are like the big kids on the block. They can handle larger materials and complex tasks. Lastly, we have CNC lathes. These are the tech geniuses, using computers to make precise cuts. You can see them working faster than a cheetah on roller skates!

| Type of Lathe | Best For | Size |

|---|---|---|

| Bench Lathe | Small projects | Compact |

| Floor Lathe | Larger materials | Medium to large |

| CNC Lathe | Precise designs | Varied |

Each lathe has its place. So whether you’re a hobbyist or a pro, pick the one that tickles your fancy!

Essential Features to Look For in Metal Lathes

Key specifications (swing over bed, distance between centers, motor power). Additional features (digital readouts, tailstock functions).Choosing a metal lathe requires understanding some key features. Here are the important specifications to consider:

- Swing over bed: This is the maximum diameter of the workpiece the lathe can handle. A larger swing allows for bigger projects.

- Distance between centers: This shows the length of the workpiece the lathe can hold. Longer distances offer flexibility for various tasks.

- Motor power: The strength of the motor affects cutting ability. A powerful motor can handle tougher materials.

Don’t forget additional features, too:

- Digital readouts: These give you precise measurements for accurate work.

- Tailstock functions: They help with drilling and support long pieces.

With the right lathe features, your metalworking projects can be easier and more successful!

Setting Up Your Lathe Workshop

Optimal workspace layout for efficiency and safety. Tips for organizing tools and materials.Creating a great space for your lathe is like arranging a fun puzzle. Keep your tools nearby but safe, so you don’t trip over them and become a human pretzel. Use your walls and shelves to store materials neatly. A well-ordered workspace can boost your productivity by up to 20%—that’s like finding an extra donut in the box! Here’s a simple table to help you organize your tools:

| Tool | Storage Solution |

|---|---|

| Lathe Chisels | Wall-mounted rack |

| Screws and Nuts | Clear jars on a shelf |

| Safety Gear | Hook near your lathe |

By keeping everything in its place, you can work smart and safely. No one wants a surprise visit from a rogue wrench! Remember, laughter is the best tool for a productive workspace.

Safety Precautions While Using a Metal Lathe

Common risks and how to mitigate them. Recommended safety gear and practices.Working with a metal lathe can be dangerous if safety isn’t a priority. Common risks include flying metal shavings, contact with moving parts, and noise exposure. To stay safe, follow these tips:

- Always wear safety glasses to protect your eyes.

- Use ear protection to guard against loud sounds.

- Keep long hair tied back and avoid loose clothing.

- Never reach into a machine while it is running.

- Learn proper lathe use before starting any project.

These simple steps can help you enjoy a safer workshop experience!

What are some main risks of using a metal lathe?

Common risks include workspace hazards and machine-related injuries. Flying shavings and entanglement pose serious dangers. Always remember: safety gear is essential!

Maintenance Tips for Longevity of Your Lathe

Daily and periodic maintenance tasks. Troubleshooting common issues.To keep your lathe running well, daily care is key. Check for loose parts, clean the machine, and oil moving bits. Regular tasks, like changing the oil every month, help too. This keeps everything smooth.

If you face problems, here are some quick fixes:

- Machine won’t turn on? Check the power source.

- Weird noises? Look for dirt or loose screws.

- Uneven cuts? Ensure the tool is sharp and set right.

With these tips, your lathe can last for years!

What are some daily maintenance tips for a lathe?

Daily maintenance tasks include checking for loose parts, cleaning the machine, and oiling moving parts. These simple steps keep your machine running smoothly.

How can I troubleshoot common lathe issues?

To troubleshoot, check the power source if it won’t start. For weird noises, look for dirt or loose screws. Ensure tools are sharp for smooth cuts.

Resources for Further Learning and Improvement

Recommended books and online courses. Community forums and support groups for lathe enthusiasts.There are many great resources to help you learn more about lathes. Books and online courses can give you useful information. Consider checking out some popular books on metalworking. They can inspire you! Online courses can teach you skills at your own pace.

- Popular Books: “The Metalworker’s Bible” and “Lathe Work: A Complete Handbook.”

- Online Courses: Websites like Udemy and Coursera offer excellent courses.

Joining community forums and support groups can also help. You can ask questions and share tips with other lathe enthusiasts. Connecting with others makes learning fun!

What are some good books for learning about lathes?

Great books include “The Metalworker’s Bible” and “Lathe Work: A Complete Handbook.” These books guide you step by step.

Where can I find online courses?

Websites like Udemy and Coursera provide many online courses on lathes.

Conclusion

In summary, setting up a lathe workshop requires careful planning and choosing quality metal lathe brands. We’ve explored popular options like Jet, Grizzly, and Smithy. Remember to consider size, features, and your budget. Now, take time to research these brands further and decide which lathe fits your needs best. Happy crafting in your new workshop!FAQs

Sure! Here Are Five Related Questions About Lathe Workshop Setup And Metal Lathe Brands:Sure! To set up a lathe workshop, you need a safe space. Make sure you have good lighting and all tools nearby. Popular metal lathe brands include Jet, Grizzly, and Harbor Freight. Each one has different features, so pick what fits your needs. Always follow safety rules when using a lathe!

Sure! Please provide me with the question you’d like me to answer.

What Are The Key Factors To Consider When Choosing A Metal Lathe For A Workshop Setup?When choosing a metal lathe for your workshop, you should think about size, power, and features. First, make sure it fits in your space. Next, check the motor power. A strong motor helps you work with tough metals. Finally, look for helpful features, like easy controls or a good safety system.

How Do Different Metal Lathe Brands Compare In Terms Of Durability And Precision?Different metal lathe brands can be good at durability and precision. Some brands use strong materials, so they last longer. Others focus on making very accurate cuts, which helps you create better parts. You might find some brands are better for tough jobs, while others are great for fine details. It’s important to choose one that fits what you need!

What Are Some Recommended Metal Lathe Brands For Beginners Vs. Experienced Machinists?For beginners, brands like Harbor Freight and Grizzly are good choices. They are easy to use and affordable. If you are more experienced, you might want to try brands like Jet or Taig. These are stronger and have better features. Always pick a lathe that fits your skill level and needs.

What Accessories Are Essential For Setting Up A Metal Lathe In A Workshop Environment?To set up a metal lathe, you need some important accessories. First, get a good set of cutting tools. These help shape the metal. Next, have a steady workbench or stand for the lathe. You’ll also need safety glasses to protect your eyes while working. Finally, get a measuring tool like a caliper to check your work.

How Can The Layout Of A Workshop Impact The Performance And Safety Of A Metal Lathe Operation?The layout of a workshop is very important for using a metal lathe safely and well. If everything is organized, you can find tools easily and work faster. A clear space around the lathe helps you move safely without tripping. Good lighting makes it easier to see what you are doing, which keeps you safe. So, a smart setup helps you work better and stay safe!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Lathe Workshop Setup And Metal Lathe Brands:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! To set up a lathe workshop, you need a safe space. Make sure you have good lighting and all tools nearby. Popular metal lathe brands include Jet, Grizzly, and Harbor Freight. Each one has different features, so pick what fits your needs. Always follow safety rules when using a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Choosing A Metal Lathe For A Workshop Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe for your workshop, you should think about size, power, and features. First, make sure it fits in your space. Next, check the motor power. A strong motor helps you work with tough metals. Finally, look for helpful features, like easy controls or a good safety system.”}},{“@type”: “Question”,”name”: “How Do Different Metal Lathe Brands Compare In Terms Of Durability And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different metal lathe brands can be good at durability and precision. Some brands use strong materials, so they last longer. Others focus on making very accurate cuts, which helps you create better parts. You might find some brands are better for tough jobs, while others are great for fine details. It’s important to choose one that fits what you need!”}},{“@type”: “Question”,”name”: “What Are Some Recommended Metal Lathe Brands For Beginners Vs. Experienced Machinists?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For beginners, brands like Harbor Freight and Grizzly are good choices. They are easy to use and affordable. If you are more experienced, you might want to try brands like Jet or Taig. These are stronger and have better features. Always pick a lathe that fits your skill level and needs.”}},{“@type”: “Question”,”name”: “What Accessories Are Essential For Setting Up A Metal Lathe In A Workshop Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, you need some important accessories. First, get a good set of cutting tools. These help shape the metal. Next, have a steady workbench or stand for the lathe. You’ll also need safety glasses to protect your eyes while working. Finally, get a measuring tool like a caliper to check your work.”}},{“@type”: “Question”,”name”: “How Can The Layout Of A Workshop Impact The Performance And Safety Of A Metal Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The layout of a workshop is very important for using a metal lathe safely and well. If everything is organized, you can find tools easily and work faster. A clear space around the lathe helps you move safely without tripping. Good lighting makes it easier to see what you are doing, which keeps you safe. So, a smart setup helps you work better and stay safe!”}}]}