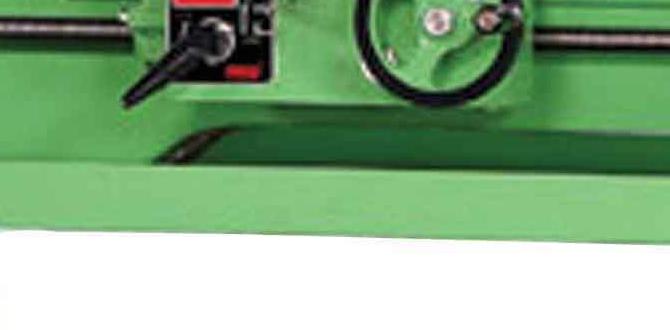

Have you ever walked into a workshop and felt a rush of excitement? The smell of metal, the sound of machines, and the sight of tools everywhere can spark inspiration. A lathe workshop is one of the most amazing places to create. But setting it up can seem tricky.

The metal lathe is a star in this workshop. It spins, shapes, and molds. But have you ever tried to use the chuck without a key? That small tool is more important than you might think! It holds everything in place while you work. Imagine trying to build something without all the parts you need.

Fun fact: Some of the best inventions started in simple workshops. With a proper lathe setup, you can be the next inventor! Are you ready to learn how to create the perfect space for your metal lathe? Let’s explore the essentials of a lathe workshop setup and see how the chuck key fits into the magic!

Essential Lathe Workshop Setup: Metal Lathe Chuck Key Guide Setting Up A Lathe Workshop Is A Crucial Step For Any Metalworking Enthusiast Or Professional. One Of The Key Components Of This Setup Is The Metal Lathe Chuck Key, Which Plays A Vital Role In Operating The Lathe Efficiently And Safely. In This Article, We Will Cover The Essentials Of Lathe Workshop Setup, Including The Importance Of The Metal Lathe Chuck Key And Tips For Optimizing Your Workspace. Understanding The Role Of The Lathe Chuck Key The Metal Lathe Chuck Key Is A Small, Often Overlooked Tool That Is Essential For Securing The Workpiece In The Chuck. Without Proper Engagement, Your Materials Can Slip, Leading To Inaccuracies And Potential Accidents. Understanding How To Use The Chuck Key Correctly Is Vital For Achieving Precise And Safe Results In Your Metalworking Projects. Setting Up Your Lathe Workshop 1. **Selecting The Right Location**: Your Workspace Should Be Spacious And Well-Ventilated. Ensure That It Is Equipped With Proper Lighting To Allow For Detailed Work. 2. **Choosing The Right Lathe**: Depending On Your Metalworking Needs, Choose A Lathe That Suits Your Projects. Consider Factors Such As Size, Motor Power, And Features. 3. **Organizing Tools And Accessories**: Keep Your Tools, Including The Lathe Chuck Key, Well-Organized And Easily Accessible. Use Pegboards, Tool Chests, Or Magnetic Strips To Store Tools Safely. 4. **Ensuring Proper Electrical Setup**: Check That Your Workspace Has The Adequate Electrical Supply Required For The Lathe And Any Additional Tools. 5. **Establishing Safety Protocols**: Implement Safety Measures To Protect Yourself While Using The Lathe. Always Wear Appropriate Personal Protective Equipment (Ppe), Including Safety Goggles And Gloves. The Importance Of The Metal Lathe Chuck Key Using The Metal Lathe Chuck Key Properly Ensures That Your Workpiece Is Secured Firmly, Reducing The Risk Of Slips During Operation. Here Are Some Tips On Its Usage: – **Double-Check Tightness**: Always Ensure That The Chuck Is Tightened Properly With The Chuck Key Before Starting Your Work. A Loose Chuck Can Lead To Dangerous Situations. – **Use The Right Chuck Key**: Different Lathe Chucks Require Specific Chuck Keys. Make Sure You Have The Right One That Fits Your Lathe. – **Store Safely**: After Use, Store The Chuck Key In A Designated Location To Prevent Misplacing It, As It Is Essential For Future Projects. Conclusion A Well-Organized Lathe Workshop Setup Is Fundamental For Effective Metalworking. The Metal Lathe Chuck Key Is A Crucial Tool That Must Be Used Correctly To Ensure Safe And Accurate Machining. By Following The Steps Outlined In This Article, You Will Be On Your Way To Creating An Efficient And Productive Lathe Workshop. Always Prioritize Safety, Organization, And The Correct Use Of Tools For An Enjoyable Metalworking Experience.

Lathe Workshop Setup: Metal Lathe Chuck Key

Setting up a lathe workshop is exciting. A crucial part of this is the metal lathe chuck key. This handy tool locks the workpieces in place. Did you know that using the right chuck key can make your projects smoother and safer? You’ll learn about different types of chuck keys and how to choose the best one for your lathe. Proper setup not only improves accuracy but also boosts creativity in your metalworking projects!Understanding the Basics of Metal Lathe

Definition and function of a metal lathe. Common applications in various industries.A metal lathe is a tool that spins metal to shape it. Think of it like a magic wand for craftsmen! It cuts, drills, and shapes materials into useful parts. You find metal lathes in many places, like car shops and factories, making everything from gears to toys. About 75% of metal machining uses lathes, showing how important they are. So, whether you’re making a fancy robot or fixing a bicycle, a metal lathe is your trusty sidekick!

| Application | Industry |

|---|---|

| Gears and Shafts | Aerospace |

| Tools and Parts | Automotive |

| Decorative Items | Crafts |

Choosing the Right Metal Lathe for Your Workshop

Different types of metal lathes and their features. Factors to consider based on project needs and budget.Choosing a metal lathe can feel like picking pizza toppings. Do you want thin crust or deep dish? There are different types of lathes, each with its own flavor. Bench lathes are perfect for small projects, while industrial lathes handle heavy tasks like a champ.

Think about your project’s size and your budget. A budget-friendly option could save some dough, but may lack features. Check for features like speed settings and precision. The right choice makes work easier and more fun!

| Type of Lathe | Features | Best For |

|---|---|---|

| Benchtop Lathe | Compact, light, low cost | Hobbyists |

| Metalworking Lathe | High precision, various sizes | General use |

| Heavy-Duty Lathe | Powerful, multiple functions | Industrial work |

Remember, a smart choice saves time, energy, and keeps the fun alive in your workshop!

The Importance of Chuck Keys in Lathe Operations

Explanation of what a lathe chuck key is. Impact of using the right chuck key on precision and safety.A chuck key is like a tiny superhero for your lathe machine. It tightens or loosens the chuck, which holds the metal piece you’re working on. Without it, your project could fly off like a rocket! Using the right chuck key is super important. It ensures precision, keeping everything in place, and boosts safety, preventing accidents. Remember, a good chuck key can make your projects smooth and fun, while a bad one can make things a little… chaotic! Who wants a surprise flying metal piece? Not me!

| Chuck Key Benefits | Impact on Operations |

|---|---|

| Ensures Precision | Accurate cuts and smoother finishes |

| Enhances Safety | Reduces risk of tool accidents |

| Improves Efficiency | Less time spent fixing mistakes |

How to Properly Use a Chuck Key

Stepbystep guide on using and securing a chuck key. Tips for preventing common mistakes during usage.Using a chuck key properly is essential for safe and effective lathe work. Follow these simple steps:

- Insert the chuck key into the chuck.

- Turn the key clockwise to tighten it. Make sure it grips securely.

- Remove the chuck key after use to avoid accidents.

To prevent mistakes, remember:

- Always check if the chuck key is fully inserted.

- Never leave the chuck key in place while operating the lathe.

- Keep your hands clear as you tighten.

Being careful and aware helps keep you safe in the workshop.

What is a chuck key used for?

A chuck key is used to tighten or loosen a lathe chuck to secure materials in place.Maintaining Your Chuck Key and Lathe for Longevity

Routine maintenance practices for chuck keys and lathes. Troubleshooting common issues related to chuck keys.Keeping your lathe and chuck key in good shape helps them work better and last longer. Regular checks and simple cleaning can make a big difference. For your chuck key, notice any wear and tear. If it feels loose, it may need replacing. Use a soft cloth to wipe away any dirt. For your lathe, keep it lubricated and check for loose parts. This way, you can avoid bigger problems down the line.

How can I fix common chuck key problems?

Many issues with chuck keys can be fixed easily. A worn key needs replacement. If the chuck doesn’t grip well, check for dirt inside. Clean it carefully. If something feels stuck, try to gently loosen it. Regular care helps keep your tools ready for action.

Here’s a quick maintenance checklist:

- Clean dirt regularly.

- Check for damage often.

- Lubricate moving parts.

- Store in a safe place.

Safety Precautions in the Lathe Workshop

Key safety protocols when working with metal lathes. Essential personal protective equipment (PPE) recommendations.Working with metal lathes can be fun, but safety should always come first! Always wear your personal protective equipment (PPE), like safety goggles and gloves. This gear keeps you safe from flying metal scraps that might say, “Surprise!” Ensure your hair is tied back—nobody wants a lathe playing tug-of-war with their locks. Regularly check your tools and machines to avoid surprises; they should work like a charm, not like a grumpy cat! Below is a snapshot of essential PPE:

| Item | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris |

| Gloves | Prevents cuts and burns |

| Ear Protection | Reduces noise exposure |

| Steel-Toed Boots | Protects feet from falling objects |

Remember, safety is no laughing matter, but a chuckle helps ease tension. Keep these tips in mind, and your workshop will be a safe space to create masterpieces!

Resources for Further Learning and Community Engagement

Recommended books, online courses, and forums for metal lathe enthusiasts. Networking opportunities within the metalworking community.Want to dive deeper into the world of metal lathes? You’re in luck! Check out these recommended books and online courses. They’ll sharpen your skills faster than a well-tuned lathe. Don’t forget to join forums where you can swap tips or your latest “oops” moments while machining. Networking can bring new friends or even mentors. Remember: every expert was once a beginner with a lathe key in hand!

| Resource Type | Examples |

|---|---|

| Books | “Metal Lathe for Beginners,” “Lathe Techniques” |

| Online Courses | Udemy, Coursera |

| Forums | Metalworking.com, Reddit |

Conclusion

In conclusion, setting up a lathe workshop with a metal lathe and chuck key is vital for quality projects. You’ll work more efficiently and safely with the right tools. Remember to keep your workspace organized. If you’re interested, explore more resources on lathe techniques to enhance your skills. Start practicing today, and enjoy the process of creating!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Chuck Keys:Of course! Here are five questions about setting up a lathe workshop and using lathe chuck keys. 1. What tools do we need for a lathe workshop? You need a lathe, tools, safety gear, and a workbench. 2. How do you set up a lathe? First, find a flat surface. Then, secure the lathe and make sure everything is tight. 3. What is a lathe chuck key? A lathe chuck key helps hold the workpiece in place on the lathe. 4. How do you use a lathe chuck key? You insert the key into the chuck and turn it to lock or unlock the piece. 5. Why is safety important in a lathe workshop? Safety stops accidents, like cuts or getting hurt. Always wear safety glasses and follow rules!

Sure! Just ask your question, and I’ll be happy to help you.

What Are The Different Types Of Chucks Used In Metal Lathes, And How Do They Affect The Lathe’S Functionality?There are different types of chucks for metal lathes. The most common ones are three-jaw chucks, four-jaw chucks, and collet chucks. Three-jaw chucks hold round objects well and are easy to use. Four-jaw chucks can grab oddly-shaped items better, but they take more time to adjust. Collet chucks are great for small pieces and keep them very steady. The type of chuck you choose changes how well the lathe works for different pieces.

How Can You Properly Align And Secure A Chuck On A Metal Lathe To Ensure Precision Machining?To align and secure a chuck on a metal lathe, first, make sure the lathe is turned off. Next, clean the areas where the chuck will sit. Place the chuck on the lathe and tighten it gently. You can check the alignment by spinning it and seeing if it wobbles. If it does, adjust it until it spins straight, then tighten it firmly.

What Safety Precautions Should Be Taken When Using A Chuck Key On A Metal Lathe?When using a chuck key on a metal lathe, always keep your hands away from the moving parts. Make sure the lathe is off before you attach or remove the chuck key. Always put the chuck key back in its holder when you’re done. If you lose the key, don’t reach into the machine. Stay focused and watch what you’re doing!

How Do You Determine The Appropriate Size And Type Of Chuck Key For Your Specific Lathe Model?To find the right chuck key for your lathe, you need to check your lathe’s manual. The manual will tell you the size of the chuck key needed. You can also measure the chuck itself with a ruler. Make sure the key fits snugly and works smoothly. This way, you can use your lathe safely and easily.

What Are Some Common Problems Associated With Using A Chuck Key, And How Can They Be Avoided?Using a chuck key can lead to a few problems. One issue is forgetting it in the drill, which can cause damage when you start the machine. We can avoid this by always checking for the key before use. Another problem is losing the chuck key, making it hard to change the drill bit. Keeping it in a designated spot helps us remember where it is.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Chuck Keys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Here are five questions about setting up a lathe workshop and using lathe chuck keys. 1. What tools do we need for a lathe workshop? You need a lathe, tools, safety gear, and a workbench. 2. How do you set up a lathe? First, find a flat surface. Then, secure the lathe and make sure everything is tight. 3. What is a lathe chuck key? A lathe chuck key helps hold the workpiece in place on the lathe. 4. How do you use a lathe chuck key? You insert the key into the chuck and turn it to lock or unlock the piece. 5. Why is safety important in a lathe workshop? Safety stops accidents, like cuts or getting hurt. Always wear safety glasses and follow rules!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Chucks Used In Metal Lathes, And How Do They Affect The Lathe’S Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are different types of chucks for metal lathes. The most common ones are three-jaw chucks, four-jaw chucks, and collet chucks. Three-jaw chucks hold round objects well and are easy to use. Four-jaw chucks can grab oddly-shaped items better, but they take more time to adjust. Collet chucks are great for small pieces and keep them very steady. The type of chuck you choose changes how well the lathe works for different pieces.”}},{“@type”: “Question”,”name”: “How Can You Properly Align And Secure A Chuck On A Metal Lathe To Ensure Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and secure a chuck on a metal lathe, first, make sure the lathe is turned off. Next, clean the areas where the chuck will sit. Place the chuck on the lathe and tighten it gently. You can check the alignment by spinning it and seeing if it wobbles. If it does, adjust it until it spins straight, then tighten it firmly.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Chuck Key On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a chuck key on a metal lathe, always keep your hands away from the moving parts. Make sure the lathe is off before you attach or remove the chuck key. Always put the chuck key back in its holder when you’re done. If you lose the key, don’t reach into the machine. Stay focused and watch what you’re doing!”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Size And Type Of Chuck Key For Your Specific Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right chuck key for your lathe, you need to check your lathe’s manual. The manual will tell you the size of the chuck key needed. You can also measure the chuck itself with a ruler. Make sure the key fits snugly and works smoothly. This way, you can use your lathe safely and easily.”}},{“@type”: “Question”,”name”: “What Are Some Common Problems Associated With Using A Chuck Key, And How Can They Be Avoided?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a chuck key can lead to a few problems. One issue is forgetting it in the drill, which can cause damage when you start the machine. We can avoid this by always checking for the key before use. Another problem is losing the chuck key, making it hard to change the drill bit. Keeping it in a designated spot helps us remember where it is.”}}]}