Have you ever wondered how metal objects are shaped and finished? The answer often lies in a lathe workshop setup. A lathe is a powerful tool that can create beautiful and precise items from metal. Among its many parts, the cross slide is key to its function. It allows you to move the workpiece in precise directions for accurate cutting.

Imagine walking into a workshop filled with the sounds of metal shaping. The spinning lathe catches your eye, transforming raw metal into art. You might think it’s complicated, but with the right setup, anyone can learn to use it.

In this article, we will explore how to set up a lathe workshop focused on the metal lathe’s cross slide. Whether you’re a beginner or someone looking to improve your skills, this guide will help you understand the basics. Buckle up for a fantastic journey into the world of lathes!

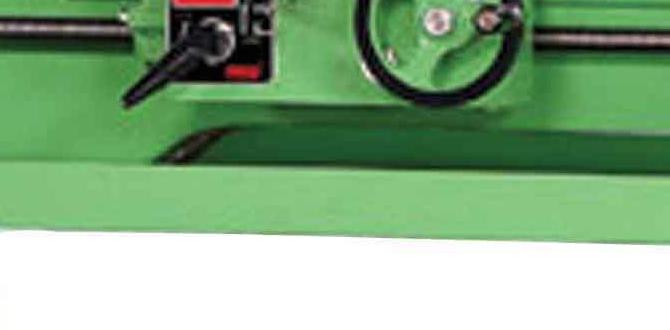

Essential Metal Lathe Cross Slide For Your Lathe Workshop Setup

Setting Up a Metal Lathe Workshop: The Cross Slide Advantage

A well-equipped lathe workshop can spark creativity. The cross slide on a metal lathe allows for precise movements, making it easier to shape and cut metal. Did you know that even small adjustments can lead to big changes in your work? Proper setup is key. Ensure your lathe is stable and aligned. This setup not only boosts accuracy but also enhances safety. A well-organized space makes every project more enjoyable and productive. Why not explore the immense possibilities of a properly set-up lathe workshop?Understanding the Metal Lathe

Definition and components of a metal lathe. Key functions and applications in metalworking.A metal lathe is a powerful tool that shapes materials like metal into precise parts. Think of it as a giant pencil sharpener for metals—minus the risk of a wobbly desk! Key components include the bed, which supports everything; the headstock, which drives the spindle; and the cross slide, which helps move tools. This magical machine spins material at high speed, letting you cut, drill, and thread with ease.

| Component | Function |

|---|---|

| Bed | Supports the entire machine |

| Headstock | Drives the spinning action |

| Cross Slide | Moves tools side to side |

In metalworking, you can create everything from simple screws to complex gears. With a metal lathe, your imagination is the only limit—besides your ability to avoid cutting yourself! So, gear up and get spinning!

Importance of a Proper Workshop Setup

Benefits of an organized lathe workshop. Safety considerations in a lathe workshop.Setting up a lathe workshop properly is like building a strong sandwich: every layer counts! An organized space boosts your efficiency, making tasks easier and faster. You won’t waste time searching for tools, which is a huge win. And let’s not forget about safety—it’s just as critical as your favorite apron. Keeping tools stored away and maintaining a clutter-free zone can prevent accidents. Remember, a tidy workshop is a happy workshop!

| Benefits of an Organized Workshop | Safety Considerations |

|---|---|

| Increased efficiency | Minimized accidents |

| Quick access to tools | Clear paths to safety |

| Better creativity | Proper ventilation |

So, make your workshop as neat as your grandma’s kitchen. Who knows? It might even impress your friends and inspire them to join in the fun. Because let’s face it, a messy workshop is like trying to bake cookies in a tornado!

Key Features of the Cross Slide

Functionality of the cross slide in lathe operations. How to adjust and maintain the cross slide for precision work.The cross slide is very important in a lathe. It helps move tools in precise directions. This movement makes sure each cut is accurate. Here are some tips to keep it working well:

- Check the slide parts for dirt.

- Use oil to keep it running smoothly.

- Adjust the knobs for better accuracy.

With these steps, you can make precise cuts and use your metal lathe effectively. It can help you create great projects!

What is the purpose of the cross slide in lathe operations?

The cross slide allows controlled movement of the cutting tool. This ensures precise shaping of metal pieces, helping achieve accurate dimensions in workpieces.

How can you maintain the cross slide for better performance?

To maintain the cross slide, check regularly for wear and tear. Clean it often, and apply lubrication to prevent rust and keep it functioning well. Tighten screws as needed to maintain its stability.

Step-by-Step Guide to Setting Up Your Lathe Workshop

Planning your workshop layout for efficiency. Assembling and positioning the metal lathe properly.Creating a great lathe workshop needs careful planning. Start by sketching your workshop layout. Make sure your metal lathe has enough space on all sides. You want to reach everything easily—like a ninja with a toolbox! Next, assemble your lathe. Place it on a sturdy bench, ensuring it’s level. A wobbly lathe is like a dance partner who can’t keep time—very awkward! Remember, a well-setup workshop makes work feel less like a chore.

| Step | Action |

|---|---|

| 1 | Plan your layout. |

| 2 | Gather all tools. |

| 3 | Assemble the lathe. |

| 4 | Position it correctly. |

Common Problems and Troubleshooting in Lathe Operations

Identifying issues related to the cross slide. Effective solutions for common lathe setup problems.Lathe operations can be tricky, especially when it comes to the cross slide. If it’s not working well, it can mess up your entire project. Common issues include sticking or misalignment. Don’t worry, troubleshooting these problems isn’t rocket science! First, check for debris. A clean slide is a happy slide. If it’s sticking, you might need to lubricate it. Also, make sure that the screws are tight but not too tight—like when you’re trying to open an overly packed jar of pickles!

| Problem | Solution |

|---|---|

| Sticking Cross Slide | Clean and lubricate |

| Misalignment | Check screw tightness |

These tips can save you time and help you avoid tears over your lathe! Remember, a happy lathe means happy crafting!

Advanced Techniques for Lathe Users

Enhancing productivity with specialized tools and accessories. Tips for mastering complex lathe operations.If you want to become a lathe superhero, special tools and accessories are your secret weapons! Using items like precision calipers will help you measure parts easily. Want to master tricky cuts? Practicing with a cutting tool holder can make complex shapes a breeze. Also, keep your workspace organized! A tidy area boosts productivity and cuts down on accidents (no one wants a surprise flying tool!).

| Tool/Accessory | Benefit |

|---|---|

| Precision Calipers | Easy measurement of parts |

| Cutting Tool Holder | Helps with complex shapes |

| Magnetic Tool Holder | Keeps tools organized |

Maintenance Practices for Longevity of Your Metal Lathe

Routine checks and maintenance schedules. Importance of lubrication and cleaning in lathe upkeep.Keeping your metal lathe in top shape is as important as keeping your snacks safe from siblings. Regular checks and a good maintenance schedule can help. Try to inspect your lathe every few weeks for any loose parts. If anything seems off, don’t wait! Fix it. Lubrication is key. Imagine trying to slide on ice without any oil—super tricky! Clean off dust and grease often to keep everything running smooth. A clean lathe is a happy lathe!

| Routine Checks | Frequency |

|---|---|

| Inspect parts for wear | Every 2 weeks |

| Lubricate moving parts | Weekly |

| Clean working area | Before each use |

With these simple steps, your metal lathe can last as long as your favorite toy—maybe even longer! Remember, a little care goes a long way.

Conclusion

In summary, setting up a lathe workshop for your metal lathe involves organizing tools and creating a sturdy workbench. Pay attention to the cross slide for accuracy in your cuts. Always prioritize safety and use the right equipment. You can start by gathering your tools and experimenting with simple projects. For more tips, check out additional resources on metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup, Specifically Focusing On The Metal Lathe Cross Slide:Sure! Here are some important things about the metal lathe cross slide. The cross slide moves side to side. You use it to adjust where the cutting tool meets the metal. Make sure it’s clean and oiled for smooth movement. Always check the settings before you start working. This helps you make accurate cuts!

Sure! Please ask your question, and I’ll answer it in a simple way for you.

What Are The Essential Components Of A Metal Lathe’S Cross Slide, And How Do They Function Together?A metal lathe’s cross slide has a few important parts. First, there’s the slide itself, which moves left and right. Next, we have the handwheel, which you turn to move the slide. There are also screws that help keep everything tight and steady. Together, they let you position the tool accurately to shape metal pieces.

How Do You Properly Align And Calibrate The Cross Slide On A Metal Lathe To Ensure Precise Machining?To align and calibrate the cross slide on a metal lathe, you first make sure it is clean. Then, loosen the screws that hold it in place. Next, you adjust it until it lines up straight. Tighten the screws to hold the cross slide firmly. Finally, check that it moves smoothly when you turn the handle.

What Common Issues Can Arise With The Cross Slide During Operation, And How Can They Be Troubleshooting Effectively?The cross slide can have a few problems while it works. It might get stuck or move unevenly. To fix it, first, check if it’s clean and free of dirt. You can also make sure the screws are tight. If it still doesn’t work well, you may need to adjust or oil the moving parts.

What Materials And Tools Are Recommended For Making Adjustments Or Repairs To The Cross Slide Of A Metal Lathe?To fix the cross slide of a metal lathe, you need a few tools and materials. First, get a wrench to tighten or loosen bolts. You’ll also need a screwdriver for smaller screws. Use oil or grease to keep moving parts smooth. Finally, have a clean cloth to wipe away dirt or old grease.

How Does The Design And Feature Set Of A Cross Slide Impact The Overall Performance And Capabilities Of A Metal Lathe?The cross slide helps you move the cutting tool side to side. A good design lets you make precise cuts. If the cross slide works smoothly, it makes your work cleaner and faster. More features can give you extra control, which helps you create better shapes. Overall, it helps you be more accurate and makes using the lathe easier.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup, Specifically Focusing On The Metal Lathe Cross Slide:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some important things about the metal lathe cross slide. The cross slide moves side to side. You use it to adjust where the cutting tool meets the metal. Make sure it’s clean and oiled for smooth movement. Always check the settings before you start working. This helps you make accurate cuts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll answer it in a simple way for you.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Of A Metal Lathe’S Cross Slide, And How Do They Function Together?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe’s cross slide has a few important parts. First, there’s the slide itself, which moves left and right. Next, we have the handwheel, which you turn to move the slide. There are also screws that help keep everything tight and steady. Together, they let you position the tool accurately to shape metal pieces.”}},{“@type”: “Question”,”name”: “How Do You Properly Align And Calibrate The Cross Slide On A Metal Lathe To Ensure Precise Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and calibrate the cross slide on a metal lathe, you first make sure it is clean. Then, loosen the screws that hold it in place. Next, you adjust it until it lines up straight. Tighten the screws to hold the cross slide firmly. Finally, check that it moves smoothly when you turn the handle.”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise With The Cross Slide During Operation, And How Can They Be Troubleshooting Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The cross slide can have a few problems while it works. It might get stuck or move unevenly. To fix it, first, check if it’s clean and free of dirt. You can also make sure the screws are tight. If it still doesn’t work well, you may need to adjust or oil the moving parts.”}},{“@type”: “Question”,”name”: “What Materials And Tools Are Recommended For Making Adjustments Or Repairs To The Cross Slide Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix the cross slide of a metal lathe, you need a few tools and materials. First, get a wrench to tighten or loosen bolts. You’ll also need a screwdriver for smaller screws. Use oil or grease to keep moving parts smooth. Finally, have a clean cloth to wipe away dirt or old grease.”}},{“@type”: “Question”,”name”: “How Does The Design And Feature Set Of A Cross Slide Impact The Overall Performance And Capabilities Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The cross slide helps you move the cutting tool side to side. A good design lets you make precise cuts. If the cross slide works smoothly, it makes your work cleaner and faster. More features can give you extra control, which helps you create better shapes. Overall, it helps you be more accurate and makes using the lathe easier.”}}]}