Imagine stepping into a workshop filled with the warm smell of metal shavings. You see a metal lathe glinting in the light, ready for action. Setting up a lathe workshop is an exciting adventure for anyone who loves working with their hands. Have you ever wondered how these machines turn blocks of metal into amazing shapes?

A well-planned lathe workshop setup can make all the difference. It’s not just about having the right tools; it’s about understanding how everything works together. From the right metal lathe gear to proper lighting, every choice counts. Plus, a good setup helps keep you safe while you create!

Did you know that lathes have been used for thousands of years? They were once powered by foot pedals before becoming electric! Today, with modern metal lathe gear, you can create precise parts for any project. So, let’s dive into what you need for the perfect lathe workshop setup! Your journey into the world of metalworking begins here.

Lathe Workshop Setup: Essential Metal Lathe Gear Guide

Understanding Lathe Workshop Setup

Setting up a lathe workshop is crucial for crafting metal projects. Readers discover how to choose the right space, tools, and safety gear. An organized setup boosts efficiency and creativity. Did you know that proper lighting can reduce errors? Arranging tools within reach saves time during work. Each gear serves a specific purpose, leading to more precise results. With a few essential tips, turning your workshop into a productive space becomes achievable and enjoyable!Choosing the Right Space for Your Lathe Workshop

Importance of adequate space and layout. Factors to consider: ventilation, lighting, and accessibility.Setting up a lathe workshop isn’t just about finding a spot; it’s about making sure the spot *makes sense*! The right space can boost your creativity and keep you safe. You need enough room to swing a wrench without knocking over your coffee (that’s just tragic). Think about ventilation to avoid smelling like a metal factory. Good lighting keeps you from turning your masterpiece into a shadow puppet show. Plus, make sure your tools are accessible—you don’t want to go on a treasure hunt every time you need a screwdriver!

| Factor | Why It Matters |

|---|---|

| Ventilation | Prevents buildup of fumes and dust. |

| Lighting | Helps you see your work clearly and avoid accidents. |

| Accessibility | Keeps your tools within reach for quick fixes. |

Basic Lathe Setup Techniques

How to properly position and secure your metal lathe. Understanding foundational adjustments for optimal performance.Positioning and securing your metal lathe correctly is vital for safe and efficient work. Ensure it stands on a stable surface. This reduces vibrations and improves accuracy. Adjust the level using spirit levels for the best results. Foundations are key; even slight tilts can affect the lathe’s performance.

- Use anchors to secure the lathe in place.

- Check alignment often for smooth operation.

- Keep tools organized near the lathe for easy access.

These techniques boost your lathe’s performance and make your projects easier. Remember, a well-set lathe is your best friend in the workshop.

How do I adjust my lathe correctly?

Check the legs for balance and use a level tool for adjustments. Tighten screws to ensure everything stays in place, and make small tweaks as needed.

Maintenance Tips for Longevity and Performance

Routine maintenance practices to extend the life of your lathe. Troubleshooting common issues in metal lathe operation.Regular care will help your lathe last longer. Check for oil and clean it each week. Look for worn or loose parts. Replace them quickly to avoid bigger problems. Ensure the bed and tools are free from rust. Remember, prevention is better than repair. If something seems off, troubleshoot before using it again. Basic checks can save you headaches later.

How can I troubleshoot common issues with my metal lathe?

Check for vibrations first. These often come from unbalanced parts. If you hear strange noises, inspect the gears. Lastly, if your cuts aren’t smooth, your tools might be dull. Always sharpen them regularly.

Quick Tips for Troubleshooting:

- Inspect for vibrations.

- Listen for unusual sounds.

- Check tool sharpness.

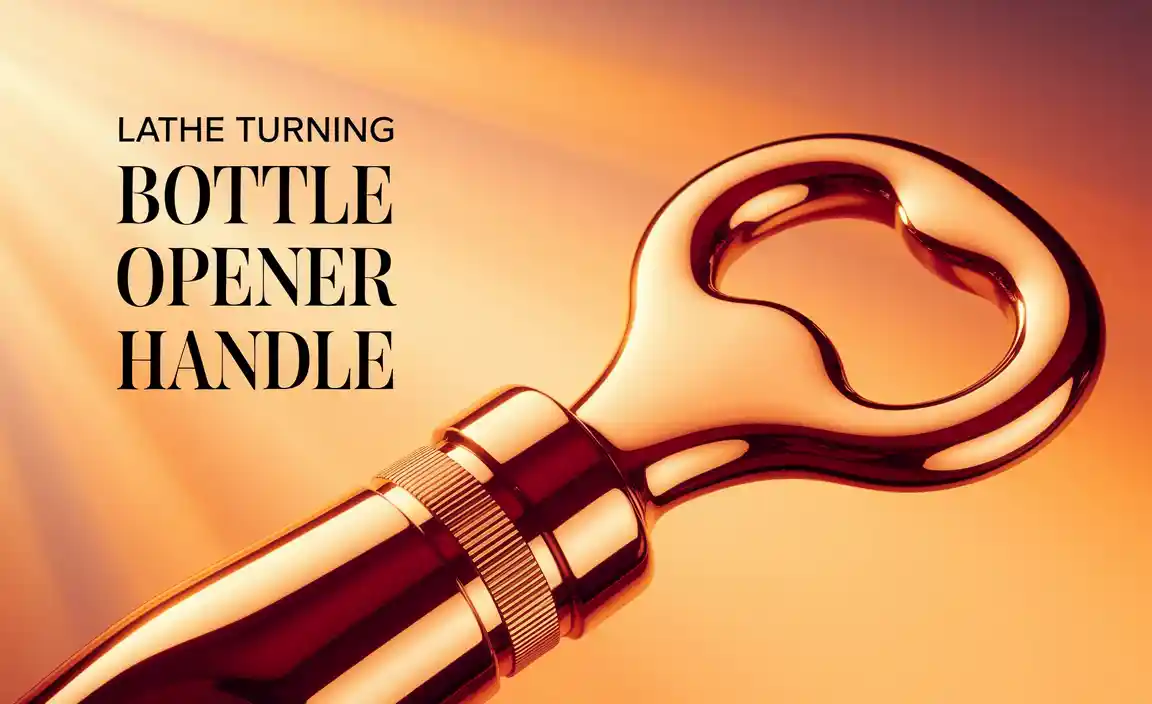

Optional Add-ons and Enhancements for Your Workshop

Explore upgrades like digital readouts and automatic feeds. Benefits of expanding your workshop with CNC capabilities.Upgrading your workshop can be fun and rewarding! Consider adding digital readouts to help you measure cuts precisely. Forget guessing! With automatic feeds, your metal lathe works like a charm, moving smoothly while you sip your coffee. CNC capabilities are another cool option. They can boost your workshop’s productivity by allowing you to create complex designs easily. Why not let machines do the heavy lifting while you take a break?

| Upgrade | Benefit |

|---|---|

| Digital Readouts | Precise measurements |

| Automatic Feeds | Smoother operation |

| CNC Capabilities | Fast, complex designs |

Conclusion

In summary, a proper lathe workshop setup is essential for using a metal lathe effectively. You need the right gear, including tools and safety equipment. Make sure to arrange your workspace neatly for easy access. Start with the basics, and don’t hesitate to explore further resources to improve your skills. Happy working and learning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of A Lathe Workshop Setup Focusing On Metal Lathe Gear:Sure! In a lathe workshop, you need tools like a lathe machine, cutting tools, and a tool rest. The lathe helps shape metal into different forms. We also need safety gear, like goggles and gloves, to protect ourselves. Lighting is important so we can see everything clearly. Finally, we should keep our workspace clean and organized to work better.

Sure! Please provide the question you want me to answer.

What Are The Essential Components Needed For A Complete Metal Lathe Workshop Setup?To set up a complete metal lathe workshop, you need a few important tools. First, get a metal lathe, which helps shape metal pieces. Next, you’ll want cutting tools to help carve the metal. Don’t forget safety gear like gloves and goggles to protect yourself. Finally, have a good workbench and proper lighting to see your work clearly.

How Do I Properly Maintain And Lubricate Gears On My Metal Lathe To Ensure Optimal Performance?To keep the gears on your metal lathe working well, you should clean them regularly. Use a soft cloth to wipe off dirt and dust. Next, apply a small amount of oil or grease designed for machines. Be careful not to use too much; a little is often enough. Finally, check the gears often to make sure they are running smoothly.

What Safety Precautions Should Be Taken When Working With Metal Lathes And Their Gear Assemblies?When working with metal lathes, you should always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight-fitting clothes to avoid getting caught in the machine. Make sure the tools are sharp to prevent slips and injuries. Always check that the area is clean and free of clutter. Lastly, never touch the machine while it’s moving.

How Can I Determine The Appropriate Gearing Ratio For Specific Metal Turning Operations?To find the right gearing ratio for metal turning, you need to understand what you are making. First, look at the material’s hardness. Softer metals need different gear settings than harder ones. Then, check the machine’s speed. You can use a simple formula: divide the speed of the machine by the speed needed for the metal. This gives you the gearing ratio to use. Always remember to test and adjust as needed!

What Are The Advantages Of Using Different Types Of Gear Systems (E.G., Change Gears Vs. Variable Speed Drives) In A Metal Lathe?Using different types of gear systems in a metal lathe has many benefits. Change gears let you control the speed and torque easily. This means you can work with different materials, like wood and metal. Variable speed drives allow smooth speed changes without stopping the machine. This helps you work faster and more accurately.