Have you ever walked into a workshop and felt that spark of creativity? Imagine standing in front of a shiny metal lathe, ready to start an exciting project. Setting up your lathe workshop can be a fun adventure. But do you know what tools you need? The metal lathe handwheel is one essential part you can’t overlook.

Picture this: you’re turning a small piece of metal, and everything feels just right. The handwheel helps you control the speed and movement, making your work smooth and easy. Did you know that many beginners often overlook this simple tool? They might not realize how crucial it is for precise work.

In this article, we will explore the best ways to set up your lathe workshop. We’ll dive into the features of the metal lathe handwheel and how it can improve your projects. Get ready to discover tips that will make your workshop a place of creativity and fun!

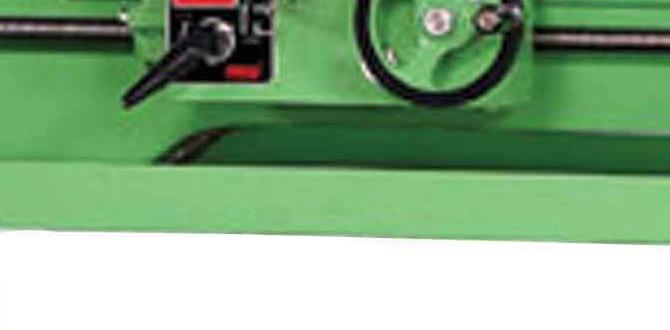

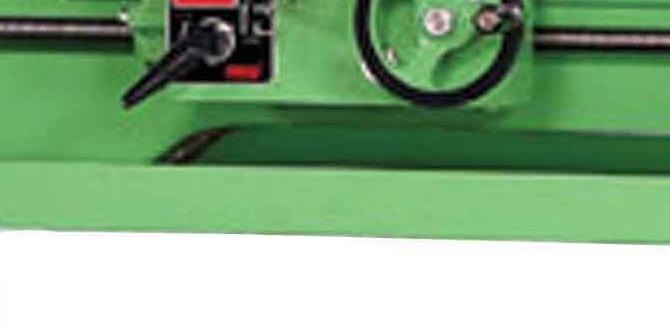

Effective Lathe Workshop Setup: Metal Lathe Handwheel Guide Setting Up A Lathe Workshop, Particularly When Focusing On A Metal Lathe Handwheel, Can Greatly Enhance Productivity And Precision In Your Machining Projects. A Well-Organized Workshop Not Only Increases Efficiency But Also Ensures Safety, Comfort, And Accessibility To Tools And Equipment. Here’S A Comprehensive Guide On How To Effectively Set Up Your Lathe Workshop With A Focus On Utilizing The Metal Lathe Handwheel. Understanding The Metal Lathe Handwheel The Metal Lathe Handwheel Is A Critical Component That Allows For Smooth Movement And Adjustment Of The Lathe’S Operations. Its Design And Mechanism Can Vary Between Different Models Of Lathes, But The Core Function Remains The Same: To Offer Operators Precise Control Over The Movement Of The Carriage And Cross-Slide. Understanding This Tool’S Functionality And Importance Can Help Ensure That Your Lathe Is Set Up Optimally. Planning Your Workshop Layout 1. **Determine The Space Requirement**: Before Setting Up Your Workshop, Measure The Area Where The Lathe Will Be Placed. It’S Important To Have Enough Space To Operate The Lathe Comfortably. 2. **Create A Workflow**: Arrange Your Equipment So That The Workflow From One Task To Another Is Smooth. Position Your Metal Lathe Handwheel Within Easy Reach. Essential Tools And Accessories Having The Right Tools On Hand Will Improve Your Lathe Workshop Setup Significantly. Ensure You Have: – **Tool Storage**: Shelving Or Tool Drawers To Keep Cutting Tools Organized. – **Measuring Instruments**: Calipers, Micrometers, And Other Tools For Precision Measurement. – **Safety Gear**: Always Include Safety Glasses, Gloves, And Hearing Protection. Setting Up The Lathe 1. **Level The Lathe**: Ensure Your Metal Lathe Is Placed On A Sturdy, Level Surface To Prevent Vibration And Ensure Accuracy. 2. **Positioning The Handwheel**: Adjust The Handwheel To A Comfortable Height So That You Can Operate It Without Strain. 3. **Check With Tools**: Once Positioned, Use A Level To Ensure Your Lathe Is Perfectly Horizontal, Adjusting As Necessary. Lighting And Ventilation Proper Lighting And Ventilation Are Essential In A Lathe Workshop. Make Sure There Are Adequate Light Sources To Illuminate The Work Area, And Ensure That There Is Good Ventilation To Dissipate Heat And Fumes Generated During Metalworking. Safety Measures Establish Safety Protocols Before Starting Any Work. Keep Flammable Materials Away From The Lathe, And Ensure That All Safety Features Of The Lathe, Including Guards And Emergency Stops, Are Inspected And Functional. Maintenance Of The Lathe Handwheel Regular Maintenance Of The Metal Lathe Handwheel Is Critical For Ensuring Its Longevity And Functionality. Clean The Handwheel Regularly, Lubricate Any Moving Parts, And Check For Any Wear That May Affect Its Operation. Conclusion Setting Up A Lathe Workshop Focused Around The Metal Lathe Handwheel Encompasses Not Only Correctly Positioning The Lathe But Creating An Efficient And Safe Working Environment. With Careful Planning And Attention To Detail, You Can Create A Space That Fosters Precision And Productivity, Allowing You To Excel In Your Metalworking Projects. Properly Setting Up Your Lathe Workshop Will Result In Better Craftsmanship—Paving The Way For Successful Projects And Innovations.

Lathe Workshop Setup: Metal Lathe Handwheel

Setting up a metal lathe workshop sounds exciting, right? A crucial part of this setup is the handwheel. It controls the lathe’s movement and helps create precise parts. Choosing a sturdy handwheel makes a big difference in performance. Did you know that a proper setup can improve your craftsmanship? Ensuring your workspace is well-organized also plays a role in safety and efficiency. With the right tools and setup, your projects will shine!Choosing the Right Metal Lathe for Your Workshop

Factors to consider when selecting a metal lathe. Comparison of different models based on features and price.Picking a metal lathe isn’t as hard as finding your car keys on a Monday morning! First, think about what you need. Some lathes are basic, while others have shiny features that make you feel like a wizard. Next, check the price. You don’t want to empty your piggy bank! Consider what each model offers. A good balance of features and cost is key. Here’s a quick table to help you compare:

| Model | Features | Price |

|---|---|---|

| Model A | Basic Speed Control | $300 |

| Model B | Digital Display, High Torque | $600 |

| Model C | All the bells and whistles! | $1500 |

Remember, the right lathe can help you make amazing stuff without turning your workshop into a disaster zone!

Essential Tools and Equipment for a Metal Lathe Workshop

List of required tools and accessories for setup. Recommended brands and quality indicators for workshop supplies.Starting a metal lathe workshop requires specific tools and accessories. Here’s a quick list of what you’ll need:

- Metal Lathe

- Handwheel

- Cutting Tools

- Caliper and Micrometer

- Workbench

- Safety Gear

Choose high-quality brands like Grizzly or Jet. Look for durable materials and ease of use. For example, a reliable lathe should have solid metal construction. Quality ensures safety and better results. Having the right tools makes your work easier and more fun!

What tools do I need for a metal lathe workshop?

You need basic tools like a metal lathe, handwheel, cutting tools, and measuring devices. Don’t forget safety gear!

Designing the Workshop Layout for Optimal Efficiency

Key principles for organizing your lathe workspace. Importance of safety considerations in workshop design.Creating an efficient lathe workspace helps you work smarter. Think about where to place tools and materials. Keep everything within easy reach. Make sure there’s enough room to move safely. Safety matters the most, so follow these tips:

- Organize tools on shelves or in drawers.

- Leave walking paths clear.

- Use good lighting to see well.

- Have a clear emergency exit.

By designing your workshop carefully, you enjoy a better experience and stay safe while using your lathe.

What are the key points for organizing a lathe workspace?

Key points include having the right tools in easy-to-reach places, keeping the area clean, ensuring good lighting, and prioritizing safety measures.

Setting Up the Metal Lathe: A Step-by-Step Guide

Detailed instructions on assembling and calibrating your lathe. Tips for ensuring accurate and precise turning operations.Assembling your metal lathe can feel like putting together a giant puzzle, but it’s easier than it seems! First, check that all parts are present. Use the manual like a treasure map. Attach the handwheel and ensure it spins smoothly. For precise turning, calibrate the machine by adjusting the tailstock and headstock. Starving your lathe of oil is a crime, so keep it well-lubricated. Here’s a quick checklist to help you:

| Step | Action | Tip |

|---|---|---|

| 1 | Check parts | Don’t lose any screws! |

| 2 | Attach handwheel | Give it a spin! |

| 3 | Calibrate | Measure twice, cut once! |

| 4 | Lubricate | Oil is your best friend. |

With everything set up correctly, you are ready to turn like a pro. Remember, practice makes perfect, so don’t hesitate to try again if your first piece isn’t a masterpiece!

Understanding the Handwheel Mechanism

Explanation of handwheel functions and its importance in operation. Common issues and troubleshooting tips related to handwheel use.The handwheel is a star player in a lathe workshop. It allows smooth manual movement for precise cuts. Think of it as the steering wheel for your metal masterpieces. If it’s wobbly or hard to turn, it can turn your creation into a disaster. Common issues include tightness and loose fittings. Tightening screws usually does the trick, but if you’re still wrestling with it, a bit of grease might help. Just remember, if all else fails, a little humor can lighten any tool’s mood!

| Common Issues | Solutions |

|---|---|

| Wobbly handwheel | Check and tighten screws |

| Handwheel turns too easily | Add lubricant |

Maintenance Tips for Your Metal Lathe and Handwheel

Routine maintenance practices to extend the lifespan of your lathe. Specific care instructions for handwheel mechanisms.Taking care of your metal lathe can help it last longer. Here are some tips:

- Clean it often. Dust and chips can cause damage.

- Check oil levels. Proper lubrication keeps parts moving smoothly.

- Tighten loose screws. A secure machine is a happy machine.

For the handwheel, keep it free from dirt. Lubricate it occasionally to prevent sticking. A well-maintained handwheel makes your work easier.

How do I care for my lathe’s handwheel?

To care for your lathe’s handwheel, keep it clean and lubricate it regularly to ensure smooth operation.

Advanced Techniques for Using Your Metal Lathe

Techniques for achieving complex geometries and finishes. Creative projects that showcase the capabilities of your lathe and handwheel.Using a metal lathe can be a blast, especially when you dive into advanced techniques! You can create cool shapes and shiny finishes that wow everyone. Want to make a spinning top that dazzles? Or perhaps a fancy doorknob? These projects show off what your lathe and handwheel can do. Try these tips:

| Technique | Purpose |

|---|---|

| Thread Cutting | Create screws or bolts |

| Step Turning | Form complex shapes |

| Parting Off | Finish pieces cleanly |

Remember, practice makes perfect! You’ll be shouting, “Look, Mom! I made this!” in no time! Your lathe can turn simple ideas into great creations, so get those gears spinning!

Resources for Further Learning and Improvement

Recommended books, online courses, and tutorials on metalworking. Community forums and workshops for networking and skill development.Looking to sharpen your metalworking skills? There are plenty of resources out there! Start with some recommended books that cover everything from basics to advanced techniques. Online courses and tutorials can be huge time-savers too. Plus, don’t forget about community forums and local workshops! These places are perfect for making friends and sharing tips—because who wouldn’t want to learn while bonding over metal shavings?

| Resource Type | Examples |

|---|---|

| Books | “Metalworking for Dummies”, “The Complete Manual of Woodworking” |

| Online Courses | Udemy, Coursera |

| Community Forums | Reddit Metalworking, WeldingWeb |

| Workshops | Local makerspaces, Tech shops |

Jump in, learn, and don’t forget to enjoy the sparks along the way—literally and figuratively!

Conclusion

In summary, setting up a metal lathe workshop with a handwheel is crucial for smooth operation. You need the right space, tools, and safety gear. Don’t forget to practice using the handwheel for better control. Explore more about lathe techniques and safety tips to improve your skills. Start working on small projects to build confidence and experience!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And The Handwheel Of A Metal Lathe:Sure! Here are five questions about setting up a lathe workshop and using the handwheel: 1. **What is a lathe?** A lathe is a machine that shapes metal or wood by spinning it. 2. **How do you set up a lathe workshop?** You need a clean space, tools, and safety gear. Make sure everything is organized. 3. **What is a handwheel?** A handwheel is a round wheel you turn by hand to move parts of the lathe. 4. **Why is safety important in a lathe workshop?** Safety is important to protect yourself from injuries. Always wear goggles and keep your hair back. 5. **How can you keep your lathe clean?** You can keep your lathe clean by wiping it down after use and removing any scraps.

Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help!

What Are The Key Considerations For Positioning The Handwheel On A Metal Lathe To Ensure Ergonomic Operation?When setting up the handwheel on a metal lathe, you want it to be easy to reach. Position it at a comfortable height, so you don’t have to bend too much. Make sure you can move it smoothly without straining your arms. It should also be close enough so you can work safely without leaning too far forward.

How Can You Effectively Calibrate The Handwheel For Precision Control During Machining Tasks On A Metal Lathe?To calibrate the handwheel on a metal lathe, start by ensuring it’s properly tightened. Then, turn the handwheel and watch how the tool moves. You can measure the movements with a ruler. Adjust the handwheel to match the measurements you want. Keep checking until it feels just right.

What Types Of Handwheels Are Available For Metal Lathes, And How Do They Differ In Functionality And Design?There are a few types of handwheels for metal lathes. The most common are the carriage handwheel and the cross-slide handwheel. The carriage handwheel moves the tool back and forth along the lathe. The cross-slide handwheel moves the tool side to side. They help us control the tool’s position for shaping metal. Each handwheel is designed for a specific type of movement.

How Does The Adjustment Of The Handwheel Impact The Accuracy Of Cuts And Overall Machining Quality On A Lathe?When you turn the handwheel on a lathe, it moves the cutting tool closer to the material. This helps make cuts more precise. If you don’t adjust it right, the cuts can be too deep or shallow. By using the handwheel correctly, we can make better and cleaner shapes. This makes our final product look nicer and work better.

What Maintenance Practices Should Be Followed To Keep The Handwheel And Associated Components Of A Metal Lathe In Optimal Working Condition?To keep the handwheel of a metal lathe working well, you should clean it regularly. Use a soft cloth to wipe off dust and dirt. You can also check for any loose parts and tighten them if needed. It’s important to oil the moving parts so they move smoothly. Finally, always store the lathe in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And The Handwheel Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about setting up a lathe workshop and using the handwheel: 1. **What is a lathe?** A lathe is a machine that shapes metal or wood by spinning it. 2. **How do you set up a lathe workshop?** You need a clean space, tools, and safety gear. Make sure everything is organized. 3. **What is a handwheel?** A handwheel is a round wheel you turn by hand to move parts of the lathe. 4. **Why is safety important in a lathe workshop?** Safety is important to protect yourself from injuries. Always wear goggles and keep your hair back. 5. **How can you keep your lathe clean?** You can keep your lathe clean by wiping it down after use and removing any scraps.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Key Considerations For Positioning The Handwheel On A Metal Lathe To Ensure Ergonomic Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up the handwheel on a metal lathe, you want it to be easy to reach. Position it at a comfortable height, so you don’t have to bend too much. Make sure you can move it smoothly without straining your arms. It should also be close enough so you can work safely without leaning too far forward.”}},{“@type”: “Question”,”name”: “How Can You Effectively Calibrate The Handwheel For Precision Control During Machining Tasks On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the handwheel on a metal lathe, start by ensuring it’s properly tightened. Then, turn the handwheel and watch how the tool moves. You can measure the movements with a ruler. Adjust the handwheel to match the measurements you want. Keep checking until it feels just right.”}},{“@type”: “Question”,”name”: “What Types Of Handwheels Are Available For Metal Lathes, And How Do They Differ In Functionality And Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few types of handwheels for metal lathes. The most common are the carriage handwheel and the cross-slide handwheel. The carriage handwheel moves the tool back and forth along the lathe. The cross-slide handwheel moves the tool side to side. They help us control the tool’s position for shaping metal. Each handwheel is designed for a specific type of movement.”}},{“@type”: “Question”,”name”: “How Does The Adjustment Of The Handwheel Impact The Accuracy Of Cuts And Overall Machining Quality On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you turn the handwheel on a lathe, it moves the cutting tool closer to the material. This helps make cuts more precise. If you don’t adjust it right, the cuts can be too deep or shallow. By using the handwheel correctly, we can make better and cleaner shapes. This makes our final product look nicer and work better.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Keep The Handwheel And Associated Components Of A Metal Lathe In Optimal Working Condition?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the handwheel of a metal lathe working well, you should clean it regularly. Use a soft cloth to wipe off dust and dirt. You can also check for any loose parts and tighten them if needed. It’s important to oil the moving parts so they move smoothly. Finally, always store the lathe in a dry place to prevent rust.”}}]}