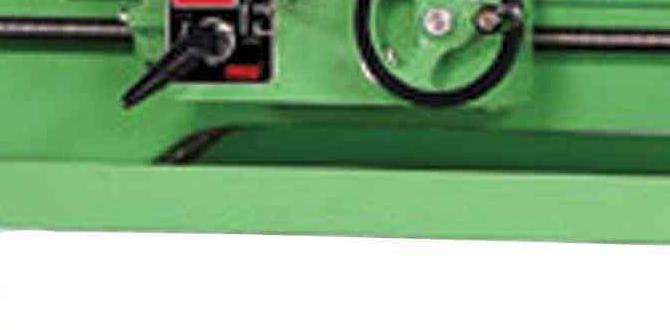

Have you ever wondered how a simple piece of metal can transform into something amazing? A lathe workshop is where this magic happens! In this space, metal lathes spin and shape materials into beautiful creations.

Setting up a lathe workshop might sound complicated, but it can be easier than you think. With the right tools and knowledge, anyone can dive into this exciting hobby. Imagine crafting your own tools or unique art pieces!

In this article, we will explore different lathe workshop setups. We will also share honest metal lathe reviews to help you choose the best one for your needs. Whether you are a beginner or a pro, there’s something here for you.

Did you know that one of the oldest machines in history is the lathe? It dates back thousands of years! This piece of equipment has helped many people bring their ideas to life.

Are you ready to discover how to set up your own lathe workshop? Let’s get started and explore the possibilities!

Lathe Workshop Setup: Expert Metal Lathe Reviews & Tips

Lathe Workshop Setup: Metal Lathe Reviews

Setting up a lathe workshop can be exciting and fun! Readers learn about the importance of choosing the right metal lathe. With various reviews available, it’s easier to see the pros and cons of each model. Tips on workspace organization help create a smooth flow for projects. Did you know that even small lathes can handle big tasks? Effective setups lead to great results, making metalworking enjoyable for hobbyists and pros alike!Essential Tools for a Metal Lathe Workshop

List of required tools and accessories for optimal performance. Importance of safety gear and maintenance tools.Setting up a metal lathe workshop requires the right tools for a smooth ride. Essential items include a lathe, cutting tools, and a good measuring tape. You’ll also need safety gear like goggles and gloves. Remember, safety isn’t a joke, but wearing a hard hat might make you feel like a construction worker on a movie set!

Here’s a quick list of must-haves:

| Essential Tools | Purpose |

|---|---|

| Lathe | Core tool for shaping metal |

| Cutting Tools | For precision cutting |

| Measuring Tape | To ensure accurate dimensions |

| Safety Goggles | Protect your eyes from flying chips |

| Gloves | Protect hands from sharp edges |

Maintenance tools, like oil and cleaning brushes, are also super important. A well-oiled lathe runs smoother than a walrus on ice! Keep things tidy and ensure your workshop is as safe as a bubble wrap factory. Remember, a clean workspace leads to a happy workspace!

Step-by-Step Guide to Setting Up Your Lathe Workshop

How to choose the right location and workspace layout. Electrical requirements and power considerations.Choosing the perfect spot for your lathe workshop is key. Look for a space that’s big enough for you to move around like a dancing robot. A well-laid-out workspace keeps tools close and projects flowing. Also, ensure you have proper electrical outlets. Your lathe will need power—like a hungry lion at dinner time!

| Electrical Considerations | Description |

|---|---|

| Voltage Requirements | Check if your lathe needs 110V or 220V. |

| Outlet Locations | Place outlets within reach of the lathe for easy access. |

| Safety First | Use circuit breakers to avoid electrical surprises. |

So, make sure your workshop has both space and power—like a superhero headquarters. Set it up right, and your lathe will be ready to create wonders!

Best Practices for Operating a Metal Lathe

Safety protocols and operational best practices. Tips for ensuring precision and accuracy in machining.Working safely with a metal lathe is key for great results. Always wear safety goggles to protect your eyes. Keep your hands away from moving parts. Regularly check your tools and machine for any issues.

To ensure precision and accuracy in your work, follow these tips:

- Measure twice, cut once.

- Use sharp tools for better cuts.

- Keep the workspace clean and organized.

Staying focused and aware will help you make excellent projects. Remember, safety and precision go hand in hand!

What are some key safety tips when using a metal lathe?

Always wear safety gear and keep your work area organized. Check tools regularly for damage.

Top Metal Lathes on the Market: Reviews and Comparisons

Detailed reviews of popular metal lathes: pros and cons. Comparison table for quick reference on specifications and prices.Many metal lathes are popular today, each with its own perks and downsides. Evaluating these factors helps you choose the right one.

- **Pro 1:** High precision and durability.

- **Pro 2:** User-friendly controls.

- **Con 1:** Can be pricey for beginners.

- **Con 2:** Heavy and needs a proper setup.

Here’s a quick comparison table to help you.

| Model | Price | Specifications |

|---|---|---|

| Lathe Model A | $1,200 | 14″ swing, 40″ bed |

| Lathe Model B | $950 | 12″ swing, 36″ bed |

| Lathe Model C | $1,500 | 16″ swing, 48″ bed |

By checking out these reviews and comparisons, you can find the perfect lathe for your workshop!

What are the key features to look for in a metal lathe?

Look for precision, ease of use, and durability. These features make a lathe efficient and enjoyable to use.

Maintenance Tips for Longevity of Your Metal Lathe

Regular maintenance tasks to keep your lathe in top condition. Common issues and troubleshooting tips.Keeping your metal lathe in good shape means doing regular tasks. Simple checks help avoid big problems. Here are some easy steps:

- Clean the lathe after use.

- Check and change oil regularly.

- Inspect belts and gears for wear.

- Keep all parts free from dust.

- Tighten any loose screws or bolts.

If you notice issues like strange noises or missed cuts, check these:

- Is the belt worn or loose?

- Is there enough lubrication?

- Are the tools sharp and clean?

With these tips, your lathe can last longer and work better.

How often should I maintain my metal lathe?

It’s best to check your lathe every use. A deep clean and full inspection should happen at least once a month.

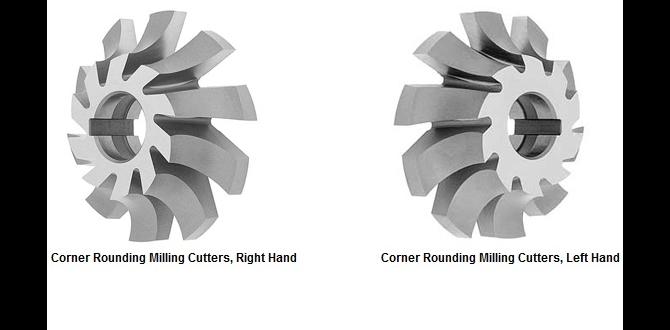

Upgrading Your Lathe Workshop: Additional Equipment to Consider

Suggested upgrades for enhancing functionality and efficiency. Importance of investing in quality accessories and components.Upgrading your workshop can be as exciting as finding a hidden treasure! Adding equipment like tool holders and cutting tools boosts productivity. Quality accessories can save time. They help create smoother cuts and longer-lasting tools. Think of them as vitamins for your lathe, giving it that extra boost! Investing in these upgrades makes a difference. Remember, **you get what you pay for**. Don’t skimp; a good lathe is a happy lathe!

| Upgrade | Benefits |

|---|---|

| Tool Holders | Faster tool changes |

| Cutting Tools | Smoother cuts |

| Chucks | Better grip on materials |

Community Feedback and Expert Opinion

Insights from experienced machinists and their workshop setups. Summary of common user experiences and recommendations.Many machinists share their thoughts on lathe workshop setups. They often highlight how important it is to have a clean and organized workspace. Some advice to consider includes:

- Choose the right size lathe for your needs.

- Keep tools within reach to save time.

- Use proper lighting for better visibility.

Overall, users find that a tidy and safe area leads to better work. Experienced machinists also stress the value of learning from others. Their insights can help new users avoid common mistakes and boost their confidence.

What do machinists say about metal lathe setups?

Machinists often say a well-arranged setup saves time and effort. Many recommend regular maintenance to keep lathe machines functioning well. Adjusting your tools correctly can also lead to better results and less frustration.

Conclusion

In summary, setting up a lathe workshop can be rewarding and fun. Choosing the right metal lathe is crucial. Read reviews to find the best options for your needs. Remember to plan your workspace carefully and prioritize safety. We encourage you to explore more about lathe types and features to make an informed choice. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Reviews:Sure! Setting up a lathe workshop is fun. You need to choose a good space with enough light and safety. When picking a metal lathe, check reviews for quality and ease of use. It’s important that the lathe fits your projects. Always gather the right tools and supplies to help you work better!

Sure! Please provide the question you’d like me to answer.

What Are The Essential Features To Consider When Setting Up A Metal Lathe Workshop?When setting up a metal lathe workshop, you need to think about space, safety, and tools. First, make sure you have enough room to move around. Next, keep safety gear like goggles and gloves nearby. You also need a good metal lathe and other tools for shaping metal. Finally, make sure to have proper lighting so you can see what you’re doing.

How Do Different Brands Of Metal Lathes Compare In Terms Of Durability And Performance?Different brands of metal lathes can be good or bad for durability and performance. Some brands use strong materials that last longer. Others might not be as sturdy, so they wear out faster. When you pick a lathe, check reviews to see how well it performs over time. We want a lathe that works well and is built to last!

What Safety Precautions Should Be Taken When Operating A Metal Lathe In A Workshop Setting?When using a metal lathe, we should always wear safety glasses to protect our eyes. It’s important to keep hair tied back and wear tight clothing to avoid getting caught in the machine. Always check if tools are sharp and in good condition before using them. Make sure your workspace is clean and free of clutter. Lastly, never rush; take your time and follow all the safety rules.

How Can One Effectively Organize Tools And Materials In A Lathe Workshop For Optimal Efficiency?To organize tools and materials in a lathe workshop, start by sorting everything. Keep similar items together, like all your wrenches or screws. Use shelves or bins to store them within easy reach. Label each storage area clearly, so you know where everything goes. Finally, keep your workspace clean and tidy to help you find things quickly.

What Common Issues Do Users Face With Their Metal Lathes, And How Can They Be Resolved Based On User Reviews?Users often face problems like bad vibrations, tools getting stuck, and uneven cuts with their metal lathes. You can fix bad vibrations by tightening loose parts. If your tools get stuck, make sure they’re clean and well-oiled. For uneven cuts, check your settings and make small adjustments. Reading tips from other users can help you solve these issues quickly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Reviews:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Setting up a lathe workshop is fun. You need to choose a good space with enough light and safety. When picking a metal lathe, check reviews for quality and ease of use. It’s important that the lathe fits your projects. Always gather the right tools and supplies to help you work better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Features To Consider When Setting Up A Metal Lathe Workshop?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up a metal lathe workshop, you need to think about space, safety, and tools. First, make sure you have enough room to move around. Next, keep safety gear like goggles and gloves nearby. You also need a good metal lathe and other tools for shaping metal. Finally, make sure to have proper lighting so you can see what you’re doing.”}},{“@type”: “Question”,”name”: “How Do Different Brands Of Metal Lathes Compare In Terms Of Durability And Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different brands of metal lathes can be good or bad for durability and performance. Some brands use strong materials that last longer. Others might not be as sturdy, so they wear out faster. When you pick a lathe, check reviews to see how well it performs over time. We want a lathe that works well and is built to last!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe In A Workshop Setting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, we should always wear safety glasses to protect our eyes. It’s important to keep hair tied back and wear tight clothing to avoid getting caught in the machine. Always check if tools are sharp and in good condition before using them. Make sure your workspace is clean and free of clutter. Lastly, never rush; take your time and follow all the safety rules.”}},{“@type”: “Question”,”name”: “How Can One Effectively Organize Tools And Materials In A Lathe Workshop For Optimal Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To organize tools and materials in a lathe workshop, start by sorting everything. Keep similar items together, like all your wrenches or screws. Use shelves or bins to store them within easy reach. Label each storage area clearly, so you know where everything goes. Finally, keep your workspace clean and tidy to help you find things quickly.”}},{“@type”: “Question”,”name”: “What Common Issues Do Users Face With Their Metal Lathes, And How Can They Be Resolved Based On User Reviews?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Users often face problems like bad vibrations, tools getting stuck, and uneven cuts with their metal lathes. You can fix bad vibrations by tightening loose parts. If your tools get stuck, make sure they’re clean and well-oiled. For uneven cuts, check your settings and make small adjustments. Reading tips from other users can help you solve these issues quickly.”}}]}