Have you ever wondered how a simple piece of metal can be turned into something amazing? A lathe workshop is full of possibilities. One of the most important parts of this process is the alignment of the metal lathe tailstock. Getting it right can make a big difference in the quality of your work.

Imagine you’re trying to build the perfect toy car but your lathe isn’t set up correctly. How frustrating would that be? You might end up with uneven cuts or wobbly pieces. That’s why understanding tailstock alignment is crucial.

Did you know that even small misalignments can lead to big problems? It’s true! This makes setting up your workshop properly so important. A well-aligned tailstock can help you achieve precise results every time you use your lathe.

In this article, we will explore the best ways to set up your lathe workshop. We’ll focus on tailstock alignment and its impact on your projects. Get ready to learn tips that can change how you work with metal!

Lathe Workshop Setup: Metal Lathe Tailstock Alignment Guide

Lathe Workshop Setup: Mastering Tailstock Alignment

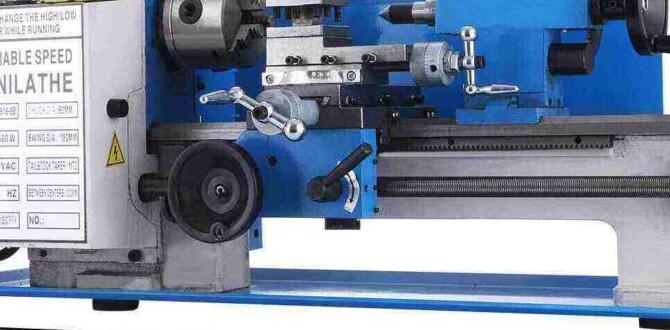

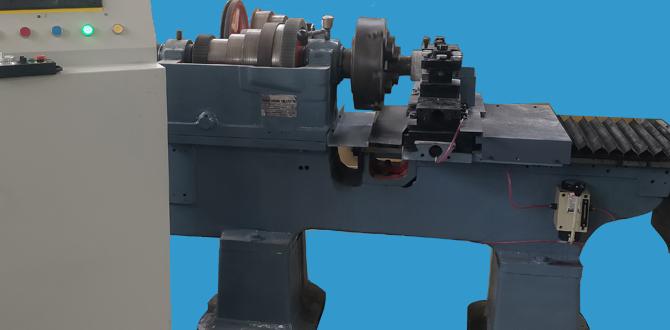

Setting up a lathe workshop can be exciting and challenging. One important aspect is the proper alignment of the metal lathe tailstock. Accurately aligning the tailstock ensures straight cuts and smooth operations. If it’s off, you’ll face issues like uneven surfaces. Imagine spending hours on a project only to find it ruined! For best results, use a dial indicator to check alignment. This simple tool can save your project and enhance your skills. Ready to get started?Understanding the Importance of Tailstock Alignment

Explanation of tailstock function in metalworking. Consequences of improper alignment.Have you ever tried to bake a cake without measuring the ingredients? Spoiler alert: it usually doesn’t turn out great! The tailstock of a lathe plays a key role in metalworking, helping support and guide your workpiece. If it’s not aligned properly, things can go sideways—like your last attempt at baking. A misaligned tailstock can lead to poor cuts, uneven surfaces, and wasted materials. Don’t let your precious metal end up looking like a wobbly jelly!

| Alignment Issue | Possible Consequence |

|---|---|

| Misalignment | Poor cuts and shapes |

| Inaccurate setup | Wasted materials |

| Excessive wear | Shorter tool life |

Essential Tools for Tailstock Alignment

List of tools required for accurate alignment. Brief description of each tool’s purpose and usage.For perfect tailstock alignment, you need a few special tools. Each tool helps you check and adjust parts accurately. Here’s a quick list:

- Caliper: Measures the distance between parts for accuracy.

- Dial Indicator: Checks alignments with precise readings.

- Taper Pin Gauge: Helps find the right size for holes.

- Level: Ensures your lathe is flat and even.

- Ruler: Gives a simple way to measure lengths.

Using these tools correctly makes alignment easier. It saves time and helps create better workpieces.

What is a dial indicator used for?

The dial indicator is used to measure small distances very accurately. It helps check if parts are lined up correctly.

Step-by-Step Guide to Setting Up Your Lathe Workshop

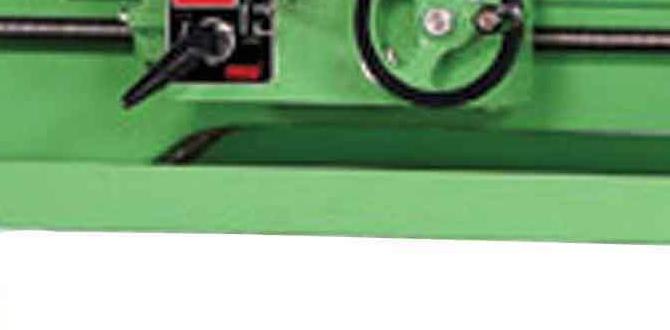

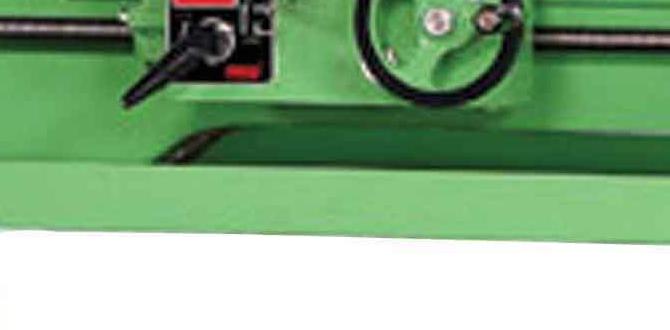

Preparing your workspace for lathe operation. How to position your lathe for optimal alignment.Start by choosing a clean, flat space for your lathe. This makes sure everything is safe and easy to reach. Keep tools nearby and organize cords to avoid tripping. Check that your lathe is level to ensure precise work. A good position is to have the lathe at waist height. This helps reduce strain on your back. Now, let’s look at some tips:

- Clear away dust and clutter.

- Ensure good lighting in the area.

- Keep tools organized on shelves or racks.

- Position the lathe away from walls for easy access.

How do I align my tailstock on a metal lathe?

To align your tailstock, first, check it is straight. Use a dial indicator for precision. This will help ensure your cuts are accurate. Adjust until it’s perfectly aligned with the headstock. A well-aligned tailstock allows better work quality and helps avoid mistakes.

Measuring Tailstock Alignment

Techniques for checking tailstock alignment. Tools needed for precise measurements.Aligning the tailstock is key for smooth turning. To check its alignment, use a few simple techniques. One method is to take a piece of round stock and center it in the chuck. Then, slide the tailstock up to it. If it’s not true, you might want to check your glasses—or your tailstock!

Tools you will need include a dial indicator and a straight edge. The dial indicator measures how far off the tailstock is. A straight edge can help you see if everything is level. Simple, right? Now, let’s see the tools:

| Tool | Purpose |

|---|---|

| Dial Indicator | Measures tailstock alignment |

| Straight Edge | Checks for straightness |

When you’re done, remember: a well-aligned tailstock will turn heads—literally! So, make these checks and keep those projects spinning smoothly.

Common Tailstock Alignment Issues

Identification of frequent problems and causes. How to troubleshoot alignment issues effectively.When working with a lathe, tailstock alignment can sometimes feel like trying to fit a square peg in a round hole. Common issues include the tailstock being too high or low, misalignment causing uneven cuts, and even wear affecting performance. These problems usually stem from improper setup or wear and tear over time. To troubleshoot, check the tailstock for levelness using a precision level or a known straight edge. Make adjustments as needed, and don’t forget to laugh at your first crooked attempt—it’s all part of the fun!

| Problem | Cause | Solution |

|---|---|---|

| High/Low Tailstock | Incorrect setup | Adjust using a precision level |

| Uneven Cuts | Misalignment | Realign tailstock properly |

| Excess Wear | Long-term use | Inspect and replace worn parts |

Adjusting the Tailstock for Perfect Alignment

Detailed methods for adjusting the tailstock. Tips for maintaining alignment over time.Aligning the tailstock correctly helps ensure accurate cuts. To adjust it, follow these steps:

- Loosen the tailstock locking screws.

- Slide the tailstock left or right as needed.

- Use a dial indicator to check alignment.

- Tighten the screws once aligned.

To maintain this alignment over time:

- Regularly check the tailstock position.

- Keep the lathe clean and free of debris.

- Handle adjustments gently, avoiding force.

Proper care helps achieve better results!

What is the best way to check tailstock alignment?

Use a dial indicator. Place it on the spindle and turn the lathe. Watch for needle movement. A steady reading means your tailstock is aligned.

Best Practices for Lathe Maintenance and Alignment

Regular maintenance tips to ensure accuracy. Importance of routine checks and adjustments.Keeping your lathe well-maintained helps it work better. Regular checks and adjustments are key. Here are some good practices to follow:

- Check for loose parts monthly.

- Clean the machine after each use.

- Oil moving parts regularly.

- Align the tailstock properly for accuracy.

Routine maintenance can prevent big problems. According to experts, small efforts can save time and money. By taking care of your lathe, you ensure it lasts longer and performs well.

Why is regular lathe maintenance important?

Regular maintenance keeps your lathe accurate and helps avoid breakdowns. Without it, your machine may not work properly. Daily checks ensure that everything runs smoothly.

Recommended Resources for Further Learning

Books, videos, and online courses for advanced techniques. Communities and forums for advice and support.If you want to learn more about metal lathe setups, many resources can help. Consider checking out some useful materials:

- Books on advanced lathe techniques.

- Online videos that show real-life demonstrations.

- Courses that teach the art of lathe work.

Joining communities and forums can also provide valuable support. You can ask questions and share experiences with others. This will help you improve your skills and confidence.

What are some good resources for learning lathe techniques?

Books, videos, and online courses are excellent resources for mastering lathe techniques. Consider engaging with communities for advice and support, as many provide practical tips and solutions.

Conclusion

In conclusion, setting up a lathe workshop requires careful tailstock alignment. This ensures your projects are precise and professional. Remember to check the alignment regularly for the best results. You can improve your skills by practicing and reading more about lathe techniques. Get started today, and enjoy creating amazing metalwork!FAQs

Sure! Here Are Five Questions Related To Lathe Workshop Setup And Tailstock Alignment:Okay! When you set up a lathe workshop, make sure your tools are easy to reach. Keep everything clean and organized. For tailstock alignment, check that it lines up with the spindle. You can use a ruler to help. Lastly, always wear safety gear to protect yourself while working!

Sure! Please provide the question you want me to answer.

How Can You Determine If The Tailstock On A Metal Lathe Is Properly Aligned With The Spindle?To check if the tailstock is aligned with the spindle, we can use a few simple steps. First, take a long, straight rod or a piece of scrap metal and put it in the tailstock. Next, make sure the rod is pointing straight towards the spindle. If the rod sticks out evenly at both ends, your tailstock is aligned. If not, we need to adjust it until it is.

What Tools And Techniques Are Recommended For Adjusting The Tailstock Alignment On A Metal Lathe?To adjust the tailstock alignment on a metal lathe, you need a few tools. First, use a dial indicator to check if everything is straight. You can also use a small wrench to loosen or tighten the tailstock. Move the tailstock slightly until it’s lined up correctly. Keep checking with the dial indicator until it looks good!

What Are The Potential Consequences Of An Improperly Aligned Tailstock During Machining Operations?If the tailstock is not aligned correctly, it can cause problems. The piece you’re working on can wobble or not fit right. This can lead to cutting mistakes or a messy product. You might also damage tools or hurt yourself. So, aligning the tailstock properly is very important for safety and good work.

How Often Should Tailstock Alignment Be Checked And Adjusted In A Well-Maintained Metal Lathe Workshop?You should check the tailstock alignment every few months. If you notice any problems with your work, adjust it right away. Regular checks help keep your lathe working well. This will make your projects turn out better, too!

Can You Explain The Differences Between Alignment Procedures For Different Types Of Metal Lathes, Such As Cnc Versus Manual Lathes?Metal lathes help shape metal into different parts. CNC lathes use computers to control movement. This makes alignment easier and more accurate. Manual lathes, however, need you to move everything by hand. You must measure carefully to get things right.