Have you ever wondered how craftsmen create amazing metal pieces? The magic often starts in a lathe workshop. Setting up a lathe workshop might sound tricky, but it’s simpler than you think. With the right metal lathe tools, you can get started on your exciting projects.

Imagine this: you walk into a small workshop filled with the sounds of spinning metal. A lathe machine is at work, shaping a simple block into something beautiful. Wouldn’t you love to experience that? By using the proper tools and techniques, you can bring your ideas to life.

In this article, we’ll explore how to set up your very own lathe workshop. We’ll cover the essential metal lathe tools you need. Get ready to dive into a world where creativity meets craftsmanship!

Essential Lathe Workshop Setup: Metal Lathe Tools Explained

Lathe Workshop Setup: Metal Lathe Tools

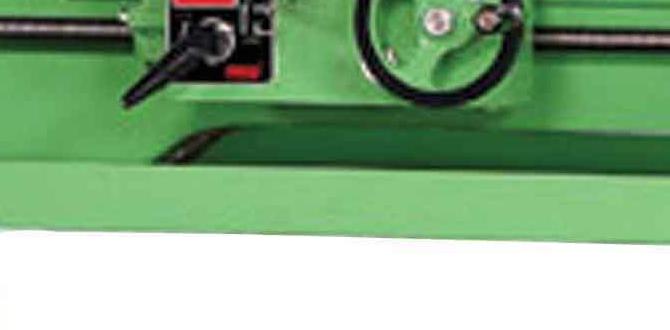

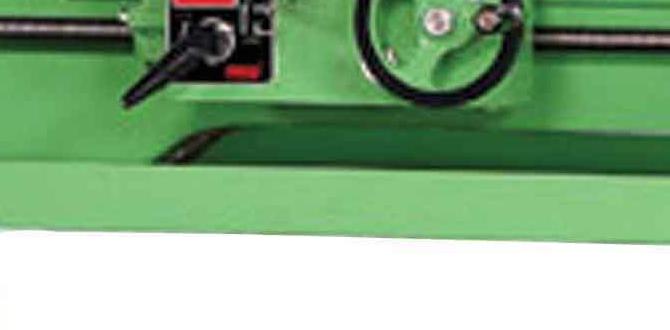

Setting up a lathe workshop can be fun and rewarding. A metal lathe is essential for shaping projects like tools or parts. Start by choosing a sturdy workbench. You’ll need essential tools like cutting tools, chucks, and tailstocks. Organize tools so you can find them quickly. Did you know the right setup can boost your creativity? Enjoy the process of crafting. Get inspired and let your imagination run wild!Choosing the Right Metal Lathe

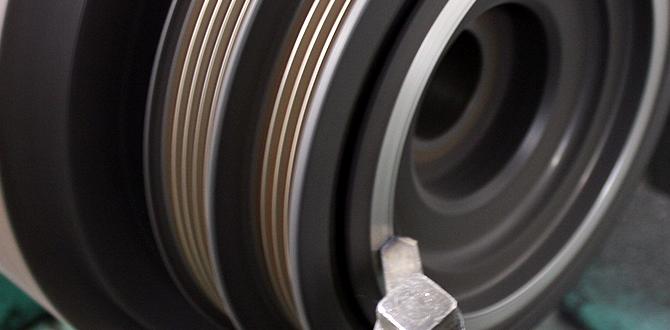

Types of metal lathes: benchtop, midi, and fullsize. Key features to consider: motor power, swing, bed length.Picking a metal lathe can feel like choosing a favorite ice cream flavor—so many options! The three main types are benchtop, midi, and full-size lathes. Benchtop lathes are great for small spaces and lighter projects, while midi lathes balance size and power. Full-size lathes? They handle the biggest jobs, but they need lots of room!

Key features to check include motor power, swing, and bed length. A strong motor means more cutting power. The swing is how big the workpiece can be, while the bed length affects the lathe’s capacity. Remember, size matters—just ask any giant cupcake!

| Type | Motor Power | Swing | Bed Length |

|---|---|---|---|

| Benchtop | Low | Small | Short |

| Midi | Medium | Medium | Medium |

| Full-Size | High | Large | Long |

Choose wisely, and soon you’ll be the proud owner of a lathe that works like a charm!

Workspace Requirements

Recommended space dimensions for a comfortable setup. Importance of ventilation and lighting in the workshop.Choosing the right space is key for a lathe workshop. A recommended area is at least 10 feet by 12 feet. This gives you room to move freely. Proper ventilation is also important. Fresh air helps keep you safe and comfortable. Good lighting brightens the workspace. You want to see everything clearly while working.

What are the workspace requirements for a lathe workshop?

The space should be cozy and safe. Aim for the measurements mentioned above. Adequate ventilation and lighting will make it easier to work. Good air keeps you healthy. Bright lights help you see your projects well.

Essential Tools for a Metal Lathe Workshop

List of musthave tools: cutting tools, tool holders, and measuring tools. Optional accessories: chucks, tailstocks, and faceplates.A metal lathe workshop needs a few important tools for success. Each tool serves a special purpose. Here’s a list of must-have items:

- Cutting Tools: These shape the metal as it spins.

- Tool Holders: These hold the cutting tools firmly.

- Measuring Tools: You need these for accurate measurements.

Also, consider adding some optional accessories:

- Chucks: These help hold the workpiece.

- Tailstocks: They support long pieces of metal.

- Faceplates: These assist in shaping bigger items.

What tools do I need for a metal lathe setup?

You should have cutting tools, tool holders, and measuring tools to start your metal lathe setup correctly. Optional tools like chucks, tailstocks, and faceplates can enhance your workshop. These tools will help you work more efficiently and safely.

Safety Measures and Best Practices

Personal protective equipment (PPE) recommendations. Safety protocols when operating metal lathes.When using a metal lathe, safety comes first. Personal protective equipment (PPE) is crucial. Always wear safety goggles to protect your eyes. Use ear protection to block noise. A dust mask helps with particles. Don’t forget gloves to shield your hands from cuts.

Follow these safety protocols:

- Keep hair tied back and avoid loose clothing.

- Ensure tools are sharp and in good condition.

- Focus on your work; no distractions.

- Know how to stop the machine quickly.

By following these tips, you help create a safer workshop. Always remember, safety is your best tool. With the right gear and practices, you can work confidently.

What is the best PPE for lathe work?

The best PPE includes safety goggles, ear protection, and gloves to keep you safe while operating a lathe.

Setting Up Your Metal Lathe

Stepbystep instructions for leveling and anchoring the lathe. Tips for organizing tools and materials in your workspace.To set up your metal lathe, follow these simple steps for leveling and anchoring:

- Find a flat surface. Use a level tool to check it.

- Adjust the lathe feet. Keep it steady and straight.

- Anchor the lathe to the floor with sturdy bolts.

For an organized workspace, it’s helpful to keep tools and materials tidy:

- Group similar tools together.

- Use shelves or drawers for easy access.

- Label containers to find items quickly.

What do I need to level a metal lathe?

You need a level tool, shims for adjustments, and sturdy bolts for anchoring. This will help keep your lathe steady and enhance your work.

Maintenance Tips for Longevity

Routine cleaning and lubrication practices. Common issues and troubleshooting solutions.To keep your metal lathe running well, regular care is important. Small tasks can make a big difference. Start with routine cleaning. Wipe down the lathe after each use. Dust and chips can cause problems. Next, don’t forget to lubricate moving parts. Oil is your friend! This keeps everything smooth and quiet.

Also, watch for common issues. If the lathe squeaks, check for dirt or lack of oil. If it stops unexpectedly, check the power source. Troubleshooting can save you time and money.

- Clean after each use.

- Lubricate every few uses.

- Check for noises or stops.

What common issues might I face with my metal lathe?

Common issues include squeaking noises, sudden stops, and uneven cuts. Regular maintenance helps prevent these problems.

Expanding Your Workshop

Considerations for adding additional machines and tools. Futureproofing your workspace for advanced projects.Adding new machines to your workshop can help you tackle bigger projects. First, think about the space you have. Do you have enough room for more tools? Next, choose tools that match your projects. This way, you’ll stay prepared for advanced work. Don’t forget to plan for easy access to all your tools. A neat setup keeps you focused and efficient.

What tools should I consider adding?

Consider items like a bandsaw, drill press, or milling machine to expand your capabilities. These tools make complex tasks easier and faster.

- Consider your project needs.

- Ensure proper electric supply for new machines.

- Stay organized to maintain efficiency.

Conclusion

In conclusion, setting up a lathe workshop takes careful planning and the right tools. You need essential lathe tools, proper workspaces, and safety equipment. By organizing your materials, you can work more efficiently. Start small, practice regularly, and consider reading more guides to improve your skills. With dedication, you can create amazing metal projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Tools:Sure! Here are five questions we could ask about setting up a lathe workshop and the tools you might need: 1. What is a lathe? A lathe is a machine that shapes metal or wood by rotating it while cutting tools shape it. 2. What tools do you need for a lathe workshop? You need tools like cutting bits, calipers, and wrenches to work safely and accurately. 3. How should you set up your lathe workshop? You should keep your lathe in a clean space, with good lighting and all your tools nearby. 4. Why is safety important in a lathe workshop? Safety is important to avoid accidents and protect yourself while using sharp tools and heavy machines. 5. Can you work with different materials on a lathe? Yes, you can work with metal, wood, and plastic, but each material needs different tools.

Sure! Please provide me with the question you’d like me to answer.

What Are The Essential Tools And Accessories Needed For A Metal Lathe Workshop Setup?To set up a metal lathe workshop, you need some important tools and accessories. First, get a metal lathe, which does the main work. You will also need cutting tools to shape the metal. A set of measuring tools, like calipers and rulers, helps you check your work. Safety gear, like goggles and gloves, keeps you safe while you work. Lastly, have a sturdy workbench to hold everything in place.

How Do You Properly Maintain And Calibrate A Metal Lathe To Ensure Optimal Performance?To maintain a metal lathe, you should clean it regularly. Wipe off dirt and oil after every use. Check all moving parts and make sure they’re not worn out. To calibrate, you can use a ruler to measure the tool’s position and adjust it if needed. Doing this helps the lathe work better and last longer.

What Safety Precautions Should Be Taken When Operating A Metal Lathe In A Workshop Environment?When using a metal lathe, you should always wear safety glasses to protect your eyes. Keep your long hair tied back and wear tight clothing so nothing gets caught. Stand clear of the machine when it’s running, and keep your hands away from the spinning parts. Make sure to read the instructions carefully before starting. Finally, keep the area clean to avoid any accidents.

How Can One Effectively Organize A Lathe Workshop To Improve Workflow And Efficiency?To organize a lathe workshop, you can start by clearing the space. Put the lathe and tools in easy-to-reach places. Use shelves or drawers for storage. Keep small items in labeled boxes so you can find them quickly. Lastly, make sure there is enough room to move around safely while you work.

What Are The Differences Between Various Types Of Cutting Tools Used On A Metal Lathe, And How Do You Choose The Right One For Specific Operations?Cutting tools on a metal lathe can be different shapes and sizes. Some have sharp edges for cutting, while others are more blunt for smoothing. You choose a tool based on what you want to do. For example, use a sharp tool for cutting and a flat tool for finishing. Always think about the material you’re working with and the job you need to do.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions we could ask about setting up a lathe workshop and the tools you might need: 1. What is a lathe? A lathe is a machine that shapes metal or wood by rotating it while cutting tools shape it. 2. What tools do you need for a lathe workshop? You need tools like cutting bits, calipers, and wrenches to work safely and accurately. 3. How should you set up your lathe workshop? You should keep your lathe in a clean space, with good lighting and all your tools nearby. 4. Why is safety important in a lathe workshop? Safety is important to avoid accidents and protect yourself while using sharp tools and heavy machines. 5. Can you work with different materials on a lathe? Yes, you can work with metal, wood, and plastic, but each material needs different tools.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Accessories Needed For A Metal Lathe Workshop Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe workshop, you need some important tools and accessories. First, get a metal lathe, which does the main work. You will also need cutting tools to shape the metal. A set of measuring tools, like calipers and rulers, helps you check your work. Safety gear, like goggles and gloves, keeps you safe while you work. Lastly, have a sturdy workbench to hold everything in place.”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Calibrate A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To maintain a metal lathe, you should clean it regularly. Wipe off dirt and oil after every use. Check all moving parts and make sure they’re not worn out. To calibrate, you can use a ruler to measure the tool’s position and adjust it if needed. Doing this helps the lathe work better and last longer.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe In A Workshop Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should always wear safety glasses to protect your eyes. Keep your long hair tied back and wear tight clothing so nothing gets caught. Stand clear of the machine when it’s running, and keep your hands away from the spinning parts. Make sure to read the instructions carefully before starting. Finally, keep the area clean to avoid any accidents.”}},{“@type”: “Question”,”name”: “How Can One Effectively Organize A Lathe Workshop To Improve Workflow And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To organize a lathe workshop, you can start by clearing the space. Put the lathe and tools in easy-to-reach places. Use shelves or drawers for storage. Keep small items in labeled boxes so you can find them quickly. Lastly, make sure there is enough room to move around safely while you work.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Various Types Of Cutting Tools Used On A Metal Lathe, And How Do You Choose The Right One For Specific Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Cutting tools on a metal lathe can be different shapes and sizes. Some have sharp edges for cutting, while others are more blunt for smoothing. You choose a tool based on what you want to do. For example, use a sharp tool for cutting and a flat tool for finishing. Always think about the material you’re working with and the job you need to do.”}}]}