Have you ever wondered how a metal lathe works? Setting up a lathe workshop can be exciting and a bit tricky. A metal lathe is a powerful tool. It can shape metal into many forms. But what if things go wrong? That’s where troubleshooting comes in. Understanding how to fix problems will help you enjoy your lathe even more.

Let’s imagine you are in your very own workshop. You just finished a new project, but suddenly, the lathe makes a strange noise. What do you do? This article will guide you through common issues and easy solutions. You’ll learn how to create the perfect lathe workshop setup and tackle any metal lathe troubleshooting you might face.

Did you know that lathes date back thousands of years? Craftsmen used them to create intricate designs. Today, you can build on that rich history. With the right setup and a little knowledge, you can master your lathe. So, let’s dive in and make your workshop a place of creativity and fun!

Lathe Workshop Setup: Essential Metal Lathe Troubleshooting Tips

Setting up a metal lathe can be tricky, but mastering it is worthwhile. First, check for proper alignment and securely mount the lathe. Regular maintenance keeps it running smoothly. Have you ever faced a vibration that shakes your project? It could be an unbalanced part. Learning these tips helps avoid common pitfalls. Fun fact: even small adjustments can enhance precision. With practice, your lathe will become a reliable tool in your workshop!

Essential Tools and Equipment for Your Lathe Workshop

List of musthave tools for a basic lathe setup. Description of necessary safety equipment.

To set up your lathe workshop, you need a few essential tools. First, a good metal lathe is crucial. You’ll also want calipers, measuring tape, and tools like drills and chisels. They help you create amazing designs. But wait! Don’t forget about safety! Safety glasses and gloves are must-haves. Trust me, you don’t want metal shavings in your eyes. Here’s a quick list of tools you might need:

| Essential Tools | Safety Equipment |

|---|---|

| Metal Lathe | Safety Glasses |

| Calipers | Gloves |

| Measuring Tape | Dust Mask |

| Drills | Ear Protection |

| Chisels | Apron |

So gear up, or you might end up with more than just cool projects—like a visit to the eye doctor!

Setting Up Your Lathe Workshop Space

Guidelines for optimal workspace layout and organization. Importance of good lighting and ventilation.

Creating the perfect lathe workshop is like building a cozy nest for your tools. Start by arranging your workspace in a way that keeps everything within reach—like a well-organized treasure map! This helps you work faster and with fewer accidents (and fewer lost tools, which can be a real pirate’s curse!).

Good lighting is crucial. Imagine trying to read in a dark room—you’d miss all the juicy details! Proper ventilation is key too, so your workshop feels fresh. Nobody wants to be in a stuffy space that makes you cough like an old wheezy dragon. Keep your workshop bright and breezy, and you’ll likely produce top-notch projects.

| Workspace Tips | Benefits |

|---|---|

| Arrange tools within reach | Faster work, fewer accidents |

| Use bright lights | See all the details |

| Ensure good ventilation | Fresh air, less coughing |

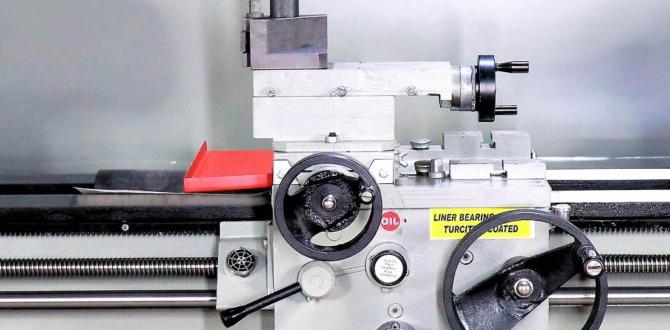

Common Metal Lathe Components and Their Functions

Breakdown of key components (headstock, tailstock, carriage). Explanation of how each part interacts during operation.

A metal lathe has three important parts: the headstock, tailstock, and carriage. Each part plays a key role during operation.

- Headstock: This part holds the spindle. It spins the material and controls speed.

- Tailstock: This part supports the other end of the material. It can be moved for different lengths.

- Carriage: This part moves the cutting tool. It adjusts to create shapes and sizes as needed.

These parts work together to shape metal. The headstock spins, the tailstock supports, and the carriage moves the tool. Understanding these parts helps avoid problems in a lathe workshop setup.

What is the function of the tailstock?

The tailstock supports the end of the workpiece and allows for adjustments. It ensures the material is secure while it spins, letting the lathe shape the metal properly.

Metal Lathe Troubleshooting: Common Issues and Fixes

List of frequent problems (e.g., vibration, misalignment). Practical solutions and adjustments for each issue.

Metal lathe issues can be a real headache, but don’t worry, we’ve got your back! One common problem is vibration. It’s like your lathe is doing the cha-cha instead of spinning smoothly. To fix this, check if it’s level and tighten loose bolts. Misalignment is another troublemaker. Your workpiece might wobble and dance around. Just adjust the tailstock alignment to get it back on track. Here’s a quick table of issues and fixes:

| Problem | Solution |

|---|---|

| Vibration | Check and tighten bolts; level the lathe. |

| Misalignment | Adjust the tailstock alignment. |

| Tool Wear | Replace or sharpen tools. |

Remember, a happy lathe makes for happy projects. Keep it tidy, aligned, and in its place. Happy turning!

Maintenance Tips for Longevity of Your Lathe

Routine maintenance checklist to keep your lathe in top condition. Importance of cleaning and lubrication.

To keep your lathe running smoothly, a little TLC goes a long way! Regularly check the areas that need attention. Cleaning and lubrication are key. Dirt loves to hide in corners. So, give your lathe a scrub with a soft cloth. Oil those moving parts like you’re giving them a spa day. It’s probably not as fun, but it helps avoid breakdowns.

| Maintenance Task | Frequency |

|---|---|

| Clean Spindle and Bed | Weekly |

| Lubricate Moving Parts | Every 100 hours |

| Check Tension and Belts | Monthly |

| Replace Worn Tools | As needed |

Keeping a routine ensures that your lathe will serve you for years. Imagine trying to fix a cake with a broken oven. Yup, that’s a lathe without maintenance! So, keep it clean and well-oiled for a hassle-free workshop experience.

Resources for Further Learning and Improvement

Recommended books, websites, and online courses for lathes. Communities and forums for connecting with other lathe enthusiasts.

Learning more about lathes can be exciting and helpful. Many great resources are available for those eager to improve. Here are some recommendations:

- Books: Find titles like “The Complete Manual of Woodworking” for practical skills.

- Websites: Check out sites like “YouTube” and “Instructables” for videos and DIY guides.

- Online Courses: Explore platforms such as “Udemy” or “Coursera” for structured lessons.

Joining online communities can also be fun. Forums like “The WoodenBoat Forum” let you connect with other lathe lovers. Share tips, ask questions, and learn together!

What is a good website for lathe enthusiasts?

One excellent site is WoodworkingTalk.com. It has forums to help you connect with other lathe users.

Are there beginner-friendly online courses for using a lathe?

Yes! Check Skillshare for easy-to-follow courses designed for beginners.

Conclusion

In summary, setting up a lathe workshop involves key tools and space planning. If you face problems with your metal lathe, check for common issues like misalignment or worn parts. Understanding these basics helps you work efficiently. You can improve your skills by practicing regularly and reading more on lathe techniques. Let’s keep learning together!

FAQs

What Are The Essential Components And Tools Needed For A Proper Metal Lathe Workshop Setup?

To set up a metal lathe workshop, you need a few important tools. First, get a good metal lathe machine. Next, have cutting tools to shape the metal. You also need safety gear, like goggles and gloves, to protect yourself. Finally, a sturdy workbench and storage for tools help keep everything organized.

How Can You Identify And Correct Common Issues Such As Vibration Or Misalignment In A Metal Lathe?

To find problems like vibration or misalignment on a metal lathe, first listen for strange noises. Then, watch the machine as it works; if it shakes, that’s a sign. You can check the lathe’s parts to see if they are lined up straight. If something isn’t right, adjust the parts carefully or ask someone for help. Always make sure everything is tight and secure before you start working.

What Safety Precautions Should Be Taken When Setting Up And Operating A Metal Lathe In A Workshop?

When using a metal lathe, we need to be very careful. First, always wear safety glasses to protect your eyes. Next, keep long hair tied back and remove any loose clothing or jewelry. Make sure the area is clean and free of clutter. Finally, never put your hands close to the moving parts while it’s working.

How Do You Determine The Correct Cutting Speeds And Feeds For Different Materials When Using A Metal Lathe?

To find the right cutting speeds and feeds for different materials on a metal lathe, you can start by checking a chart. These charts show safe speeds based on the material you are using. You also need to know the size of your tool and the workpiece. After trying it out, you can adjust if it feels too fast or too slow. Always be careful and make sure everything runs smoothly.

What Troubleshooting Steps Should Be Taken If The Metal Lathe Is Producing Inconsistent Or Poor-Quality Finishes On Machined Parts?

First, check the cutting tool. Make sure it’s sharp and not damaged. Next, look at the speed settings. If it’s too fast or too slow, adjust it. Also, clean the machine to remove any dirt or chips. Finally, test different materials to see if they give better results.