Have you ever wondered how a simple piece of metal can be turned into a work of art? If you’re curious about creating amazing projects with a metal lathe, you’re in the right place. Setting up a lathe workshop is an exciting adventure that can spark your creativity.

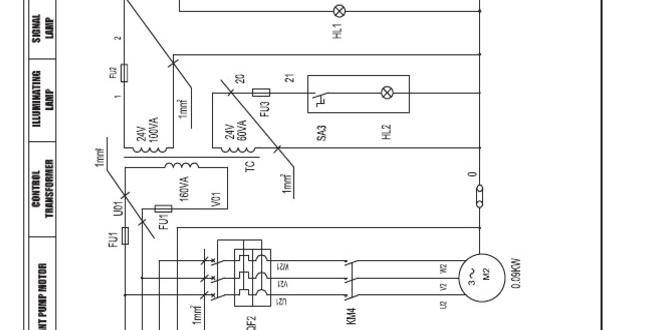

One essential part of this process is understanding the metal lathe wiring diagram. It’s like a roadmap guiding you through the setup. This diagram helps you connect everything properly and safely. Imagine trying to build a Lego set without instructions; it could get messy!

Picture this: you step into your workshop, and everything is in its right place. Your lathe is ready, and the tools are within reach. With the right setup, you’ll feel like a master craftsman before you even start. Let’s dive in and discover how to create the perfect lathe workshop that brings your ideas to life!

Lathe Workshop Setup: Metal Lathe Wiring Diagram Guide

Key Points on Lathe Workshop Setup and Wiring Diagrams

Setting up a metal lathe workshop starts with a solid plan. Did you know that proper wiring can enhance safety and efficiency? A clear wiring diagram is crucial for understanding connections. It shows how to link the lathe to the power supply easily. When you organize your workspace and tools, you boost productivity. The right setup not only helps you create quality work but also makes projects more enjoyable. Who doesn’t love a smooth-running machine?Understanding Metal Lathes

Definition and types of metal lathes.. Common applications in various industries..Metal lathes are cool machines that spin metal to shape it. You can find different types like engine lathes and CNC lathes. Each serves a unique purpose! They are handy in many industries, making everything from car parts to tiny gadgets.

Take a look at this table of types and uses:

| Type | Common Applications |

|---|---|

| Engine Lathe | Machining shafts and cylinders |

| CNC Lathe | Creating complex designs quickly |

| Toolroom Lathe | Precision work for small parts |

With a metal lathe, you can turn your metal dreams into reality! Just be careful not to turn it into a metal pretzel. Remember, safety first, fun second!

Essential Tools and Equipment for Lathe Workshops

Comprehensive list of tools needed.. Importance of each tool in the setup..Setting up a lathe workshop is like building your dream treehouse but with fewer splinters! First on the list are lathe machines themselves. They shine in shaping metal into various forms. Then, add measuring tools, like calipers to ensure everything is precise—no one wants a wobbly table leg! Next, include cutting tools for slicing through metal like a hot knife through butter. Finally, a reliable workbench gives you a solid surface to work on, preventing your creations from bouncing away! Below is a handy table to summarize these essential tools:

| Tool | Importance |

|---|---|

| Lathe Machine | Shapes metal into desired forms. |

| Measuring Tools | Ensures precision and accuracy. |

| Cutting Tools | Helps cut metal efficiently. |

| Workbench | Stable surface for safe working. |

Each tool is crucial for a successful workshop. Remember, a great setup makes every project smoother and more fun! Who knew metalworking could be this exciting?

Planning Your Lathe Workshop Layout

Factors to consider for optimal workflow.. Tips on space management and organization..Creating a great lathe workshop layout makes work easier and safer. First, think about your workflow. Place tools where you need them most. This cuts down on extra steps and saves time. Keep the area tidy to avoid accidents.

Space management is essential. Consider these tips:

- Store frequently used tools within reach.

- Use shelves to organize materials.

- Leave enough space to move around safely.

Remember, a well-planned space boosts creativity and efficiency.

What is an ideal layout for a lathe workshop?

The best layout allows easy access to tools and materials. Make sure to keep your lathe as the main focus, with other equipment nearby. This setup enhances productivity and comfort.

Some tips include:

- Arrange tools in a circular pattern around your lathe.

- Leave enough room for larger projects.

- Consider natural light for a better atmosphere.

Step-by-Step Wiring Guide for Metal Lathes

Detailed instructions on wiring connections.. Troubleshooting common wiring issues..Wiring a metal lathe is fun and important. First, connect the motor wires to the power supply. Next, check your connections carefully. If the lathe does not turn on, consider these tips:

- Make sure the power supply is on.

- Check for loose wires.

- Test the fuse for breaks.

Follow these simple steps, and you’re on your way to using your lathe safely!

What should I do if my lathe doesn’t work?

Check the power source, inspect all connections, and ensure the motor is functional.

Safety Measures in Lathe Workshops

Essential protective equipment for operators.. Best practices for maintaining safety in the workspace..Using a lathe can be fun, but safety is key! Operators should always wear protective gear like goggles and gloves, just in case things get wild. Remember, “safety first, but fun doesn’t have to take a backseat!” Keeping the workspace clean and organized is a must; it helps avoid accidents. Always check the equipment before use. Here’s a quick glance at essential safety gear:

| Protective Equipment | Purpose |

|---|---|

| Safety Goggles | Protects eyes from flying debris |

| Gloves | Prevents cuts and injuries |

| Ear Protection | Reduces noise exposure |

| Dust Mask | Safeguards from inhaling harmful particles |

Following these simple rules can keep you safe while enjoying the excitement of turning metal into art!

Regular Maintenance for Longevity of Metal Lathes

Importance of routine checks and servicing.. Tips for extending the lifespan of your lathe machine..Keeping your metal lathe in top shape is key for a long life. Regular checks can save you from costly repairs and make your projects run smoother. It’s like giving your lathe a spa day! Remember to clean it often and check the oil levels. Also, keep a close eye on those belts; they love to stretch out and relax too much if you let them!

| Tip | Description |

|---|---|

| Clean Regularly | Dust and chips can mess with performance. |

| Lubricate Parts | Oil keeps everything moving smoothly. |

| Check Belts | Tight belts mean tight work; loose belts mean hiccups! |

By following these simple tips, your lathe can last for years. Remember, a well-cared lathe is a happy lathe! And a happy lathe makes for happy projects!

Resources for Further Learning and Support

Recommended books, websites, and forums.. Where to find professional help and community support..Learning about metal lathes can feel like a whirlwind, but you don’t have to go it alone! A few great resources make this journey a breeze. Check out some recommended books like “Lathe Basics” for practical tips. Websites like YouTube have tons of tutorials. Online forums are awesome places to ask questions and share your projects. Don’t be shy; even the most seasoned pros learn from each other!

| Resource Type | Names |

|---|---|

| Books | “Lathe Basics” |

| Websites | YouTube, The Home Machinist |

| Forums | Machinery Forums, Reddit |

If you need professional help, local workshops often offer classes. These can be a great way to learn hands-on. Remember, every expert was once a beginner, so embrace the learning process and have fun! After all, if lathes can make beautiful things, imagine what you can create!

Conclusion

In conclusion, setting up a lathe workshop with proper wiring is essential for safety and efficiency. We learned that understanding a metal lathe wiring diagram helps you connect everything correctly. You can improve your skills by practicing and learning more about lathe operations. Don’t hesitate to explore further resources for tips and guides. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Wiring Diagrams:Sure! Setting up a lathe workshop means you need space and tools. First, find a clean, flat surface for the lathe. Next, gather tools like wrenches and safety glasses. For wiring, follow the metal lathe’s diagram carefully. This helps make sure everything works safely and correctly.

Sure! Please provide the question you’d like me to answer.

What Are The Essential Components Required For Wiring A Metal Lathe In A Workshop Setup?To wire a metal lathe, you need a few important parts. First, get a power supply to give it electricity. Next, you need a switch, so you can turn it on and off easily. Wires connect everything together, creating the circuit. Lastly, make sure you have safety tools like fuses to protect against accidents.

How Can I Ensure Proper Electrical Safety When Wiring A Metal Lathe?To keep safe when wiring a metal lathe, first, always turn off the power before you start. Use rubber gloves and shoes to protect yourself from electric shocks. Make sure all wires are connected tightly and are in good shape. Check that your lathe is grounded, which means it has a safe connection to the earth. Lastly, always ask an adult or expert for help if you’re unsure about anything.

What Specific Wiring Diagram Should Be Followed For A Three-Phase Metal Lathe?To wire a three-phase metal lathe, you need a specific diagram. First, look at the lathe’s manual for the wiring guide. This shows where to connect the wires for power. You usually connect three wires to the motor. Make sure to follow the color codes for safety. If you’re unsure, ask an adult for help!

How Do I Determine The Appropriate Power Supply Requirements For My Metal Lathe?To find the right power supply for your metal lathe, first check the lathe’s manual. It will tell you how much power it needs in watts or volts. Next, look at your home outlets. They usually provide 120 volts, but your lathe might need more. If it does, you may need a special outlet or an adapter. Always ask an adult for help if you’re unsure!

What Common Troubleshooting Steps Should I Take If My Metal Lathe Does Not Power On After Wiring?First, check if the power cord is plugged in. Make sure the outlet works by trying another device. Next, look for a switch on the lathe and make sure it’s turned on. If it still doesn’t work, check the wiring connections to see if anything is loose. Finally, consult the user manual for more help.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Setting up a lathe workshop means you need space and tools. First, find a clean, flat surface for the lathe. Next, gather tools like wrenches and safety glasses. For wiring, follow the metal lathe’s diagram carefully. This helps make sure everything works safely and correctly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Required For Wiring A Metal Lathe In A Workshop Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe, you need a few important parts. First, get a power supply to give it electricity. Next, you need a switch, so you can turn it on and off easily. Wires connect everything together, creating the circuit. Lastly, make sure you have safety tools like fuses to protect against accidents.”}},{“@type”: “Question”,”name”: “How Can I Ensure Proper Electrical Safety When Wiring A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep safe when wiring a metal lathe, first, always turn off the power before you start. Use rubber gloves and shoes to protect yourself from electric shocks. Make sure all wires are connected tightly and are in good shape. Check that your lathe is grounded, which means it has a safe connection to the earth. Lastly, always ask an adult or expert for help if you’re unsure about anything.”}},{“@type”: “Question”,”name”: “What Specific Wiring Diagram Should Be Followed For A Three-Phase Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a three-phase metal lathe, you need a specific diagram. First, look at the lathe’s manual for the wiring guide. This shows where to connect the wires for power. You usually connect three wires to the motor. Make sure to follow the color codes for safety. If you’re unsure, ask an adult for help!”}},{“@type”: “Question”,”name”: “How Do I Determine The Appropriate Power Supply Requirements For My Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right power supply for your metal lathe, first check the lathe’s manual. It will tell you how much power it needs in watts or volts. Next, look at your home outlets. They usually provide 120 volts, but your lathe might need more. If it does, you may need a special outlet or an adapter. Always ask an adult for help if you’re unsure!”}},{“@type”: “Question”,”name”: “What Common Troubleshooting Steps Should I Take If My Metal Lathe Does Not Power On After Wiring?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, check if the power cord is plugged in. Make sure the outlet works by trying another device. Next, look for a switch on the lathe and make sure it’s turned on. If it still doesn’t work, check the wiring connections to see if anything is loose. Finally, consult the user manual for more help.”}}]}