Have you ever wondered how a simple key can make a big difference in machining? The metal lathe chuck key is a small tool. Yet, it’s vital for keeping your lathe running smoothly. Without it, your projects could come to a halt. Isn’t that a scary thought?

Imagine working on your latest creation, only to find that you can’t adjust the chuck. It’s frustrating and could ruin your hard work. That’s why a maintenance guide for your metal lathe chuck key is so important. It helps you understand how to care for this handy tool.

Did you know that by regularly maintaining your chuck key, you can extend its life? It’s true! With a few easy steps, your projects can go off without a hitch. Stick around to learn how to keep your metal lathe chuck key in top shape!

Essential Maintenance Guide For Metal Lathe Chuck Key

Maintenance Guide for Metal Lathe Chuck Key

Keeping your metal lathe chuck key in top shape is essential for safe operation. Regularly check for wear and tear. A damaged chuck key can lead to accidents or poor machining results. Did you know that a poorly maintained chuck key can cause your workpiece to slip? Always clean the key after use and store it properly. By following these simple maintenance tips, you can ensure smooth and effective lathe operation. Stay safe while working!Understanding the Metal Lathe Chuck Key

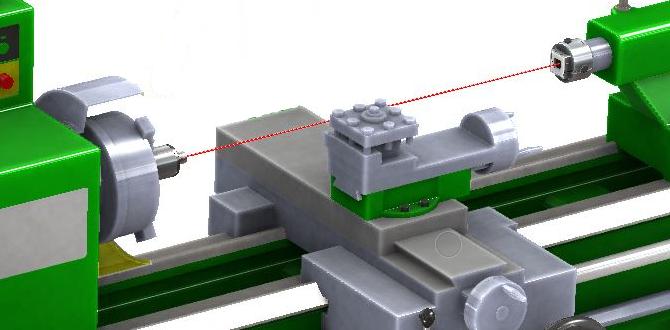

Definition and purpose of a chuck key. Types of chuck keys used in metal lathes.A chuck key is a special tool that helps open and close the chuck on a lathe. Think of it as the key to a treasure chest, but this treasure helps you hold and spin metal! It ensures that the workpiece is secure while you work on it. There are two main types of chuck keys used in metal lathes: the standard chuck key and the T-handle chuck key. Each one has its own perks that make them handy for different tasks.

| Type of Chuck Key | Description |

|---|---|

| Standard Chuck Key | Common and easy to use for most lathes. |

| T-Handle Chuck Key | Offers better grip and control for tough jobs. |

Remember, the right key makes all the difference. You wouldn’t want your treasure chest to fly open, would you?

Importance of Regular Maintenance

Benefits of maintaining the chuck key. Consequences of neglecting maintenance.Keeping your chuck key in top shape is like giving your metal lathe a daily hug! Regular maintenance helps to ensure smooth operation, making your work easier and more enjoyable. If you skip this upkeep, you risk things like rust, wear, or even a chuck key snapping during use—yikes! That could ruin your project or, worse, lead to injuries. So, keep that chuck key shiny and functional to avoid unplanned trips to the toolbox or the doctor!

| Benefits of Maintenance | Consequences of Neglect |

|---|---|

| Ensures smooth operation. | Increased wear and breakage. |

| Improves work quality. | Potential safety hazards. |

| Extends the life of the lathe. | Higher repair costs. |

Common Issues Faced with Chuck Keys

Worn out teeth and its impact on performance. Misalignment issues and solutions.Chuck keys can face some funny issues. First, worn-out teeth can lead to slipping during work. This means your project might start looking more like a “modern art” piece! Next, misalignment can cause problems too. Is your chuck key dancing offbeat? It’s time to fix it! Here’s a simple table to help you spot the problems:

| Issue | Description | Solution |

|---|---|---|

| Worn Teeth | Teeth lose grip, causing slips. | Replace the chuck key. |

| Misalignment | Chuck doesn’t fit right. | Align properly to secure grip. |

Addressing these issues can improve performance. Remember, a well-maintained chuck key is key to smoother projects!

Tools and Supplies Needed for Maintenance

Essential tools for maintaining a chuck key. Recommended lubricants and cleaning supplies.To keep your chuck key in top shape, you need some essential tools. First, grab a wrench. It helps tighten and loosen your chuck key without fuss. Next up, get a clean cloth to wipe away dirt. For those tricky spots, a brush works wonders. Lubrication is key too! A good quality machine oil will make things run smoothly. Don’t forget a mild cleaner to keep everything fresh. Let’s look at the tools you’ll love:

| Tool | Purpose |

|---|---|

| Wrench | Tightens/looses the chuck key |

| Clean Cloth | Wipes off dirt |

| Brush | Cleans tight spaces |

| Machine Oil | Lubricates for smooth use |

| Mild Cleaner | Keeps everything fresh |

These handy items are all you need. Time to make that chuck key gleam! Remember, a happy tool makes a happy worker!

Step-by-Step Maintenance Process

Cleaning the chuck key properly. Inspecting and replacing worn parts.Taking care of your chuck key is key to keeping your metal lathe running smoothly! First, give it a good clean. Use a soft cloth to wipe off dust and grime. After that, check for any worn parts. If the teeth look more like a toddler’s toothbrush, it’s time for a replacement! Regular checks can save you from bigger issues down the road.

| Check Every | Action |

|---|---|

| Weekly | Clean the chuck key |

| Monthly | Inspect for wear and tear |

| As Needed | Replace old parts |

Remember, a little care goes a long way. It’s like giving your tools a spa day—everyone feels better after a nice cleanup!

Tips for Prolonging the Life of Your Chuck Key

Best practices for usage. Storage recommendations to avoid damage.To make your chuck key last longer, follow some easy tips. First, always use it properly. Don’t use it for prying open stubborn cans or as a doorstop. That could end badly! Always store your chuck key in a safe spot, away from moisture and heavy tools. A drawer works great. Check out the table below for more tips!

| Practice | Description |

|---|---|

| Proper Usage | Only use the chuck key for its intended purpose. |

| Smart Storage | Keep it dry and away from heavy items. |

By treating your chuck key like a treasured pet, it will serve you well for years. Remember, a happy chuck key is a long-lasting chuck key!

When to Seek Professional Help

Signs that indicate professional maintenance is needed. How to choose a reliable service provider.Many signs show it’s time to get help with your lathe chuck key. Listen for strange noises, like grinding or clanking. Feel for vibrations that seem off. Notice if the chuck key is stuck or not working smoothly. These issues can mean more than a simple fix.

When searching for a service provider, look for someone with good reviews. Check that they have experience with metal lathe tools. Ask them questions to feel confident in their skills.

What are signs that your lathe chuck key needs repair?

Look for loud noises, unusual vibrations, or if the key doesn’t fit well. These might suggest it’s time for professional help.

How to find a good service provider?

- Check online reviews

- Ask friends for recommendations

- Look for specialists in metal lathe repair

Conclusion

In summary, a maintenance guide for your metal lathe chuck key helps you keep it in good shape. Clean it regularly and check for wear or damage. This simple care ensures your lathe works smoothly and lasts longer. For more tips, consider reading up on lathe maintenance strategies. You’ll see how easy it is to keep your workspace efficient!FAQs

What Are The Key Signs That Indicate A Metal Lathe Chuck Key Needs Maintenance Or Replacement?You should check your metal lathe chuck key for a few signs. If it feels loose or wobbly, it may need fixing. Look for cracks or breaks in the metal. If the handle is hard to turn, that’s a problem, too. Keeping it in good shape helps you work better!

How Often Should You Perform Maintenance On Your Metal Lathe Chuck Key To Ensure Optimal Performance?You should check your metal lathe chuck key regularly, like once a month. Clean it to remove dirt and oil. Look for any damage, like cracks or bends. If it’s worn out, replace it right away. This keeps your lathe working well!

What Is The Proper Cleaning Procedure For Maintaining A Metal Lathe Chuck Key?To clean a metal lathe chuck key, you should start by wiping it with a dry cloth. This removes dust and dirt. If it’s really dirty, use warm soapy water and a soft brush. After cleaning, dry it completely. Finally, keep it in a safe, dry place to prevent rust.

How Do You Properly Store A Metal Lathe Chuck Key To Prevent Damage Or Wear?To store a metal lathe chuck key, find a safe spot where it won’t get lost. You can use a drawer or a small container. Make sure it’s always dry, as moisture can cause rust. Keep it away from heavy tools to avoid bending or breaking. By doing this, you help it last longer and work better when you need it!

What Safety Precautions Should Be Taken When Using And Maintaining A Metal Lathe Chuck Key?When using a metal lathe chuck key, always keep your hands clear of moving parts. Make sure to remove the chuck key right after tightening the chuck. Never leave the key in the chuck, as it can cause accidents. Regularly check the key for damage and keep it clean. Always wear safety glasses to protect your eyes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Signs That Indicate A Metal Lathe Chuck Key Needs Maintenance Or Replacement? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check your metal lathe chuck key for a few signs. If it feels loose or wobbly, it may need fixing. Look for cracks or breaks in the metal. If the handle is hard to turn, that’s a problem, too. Keeping it in good shape helps you work better!”}},{“@type”: “Question”,”name”: “How Often Should You Perform Maintenance On Your Metal Lathe Chuck Key To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check your metal lathe chuck key regularly, like once a month. Clean it to remove dirt and oil. Look for any damage, like cracks or bends. If it’s worn out, replace it right away. This keeps your lathe working well!”}},{“@type”: “Question”,”name”: “What Is The Proper Cleaning Procedure For Maintaining A Metal Lathe Chuck Key? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean a metal lathe chuck key, you should start by wiping it with a dry cloth. This removes dust and dirt. If it’s really dirty, use warm soapy water and a soft brush. After cleaning, dry it completely. Finally, keep it in a safe, dry place to prevent rust.”}},{“@type”: “Question”,”name”: “How Do You Properly Store A Metal Lathe Chuck Key To Prevent Damage Or Wear? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To store a metal lathe chuck key, find a safe spot where it won’t get lost. You can use a drawer or a small container. Make sure it’s always dry, as moisture can cause rust. Keep it away from heavy tools to avoid bending or breaking. By doing this, you help it last longer and work better when you need it!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using And Maintaining A Metal Lathe Chuck Key? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe chuck key, always keep your hands clear of moving parts. Make sure to remove the chuck key right after tightening the chuck. Never leave the key in the chuck, as it can cause accidents. Regularly check the key for damage and keep it clean. Always wear safety glasses to protect your eyes.”}}]}