Have you ever wondered how machines like metal lathes work? These incredible tools shape metal into useful parts. But what happens when they start to wear down? A little care goes a long way in keeping them running smoothly.

This is where a maintenance guide comes in handy. Whether you are a hobbyist or a professional, understanding maintenance is important. A metal lathe CNC retrofit can give your old machine new life, making it more efficient and precise.

Imagine being able to turn your worn-out lathe into a modern powerhouse. It sounds amazing, right? Taking the time to learn about upkeep can save money and time. In this article, we will explore the essential steps of maintaining your metal lathe. You’ll find tips that keep your machine in top shape.

Get ready to uncover secrets that will help your lathe last longer. Maintenance doesn’t have to be a chore. With the right knowledge, you can enjoy using your metal lathe for many years to come!

Comprehensive Maintenance Guide For Metal Lathe Cnc Retrofit

Maintenance Guide for Metal Lathe CNC Retrofit

Keeping your metal lathe in top shape is key for quality results. A CNC retrofit enhances your lathe’s capabilities but requires careful maintenance. Did you know that regular oiling can extend your machine’s life? Simple tasks like cleaning and checking for wear can prevent costly repairs. Understanding your machine’s needs helps ensure it runs smoothly. Are you ready to take your lathe operations to the next level? A little effort goes a long way in staying productive!Essential Components of CNC Metal Lathes

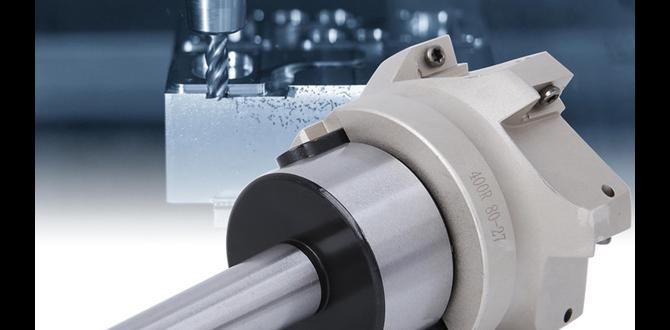

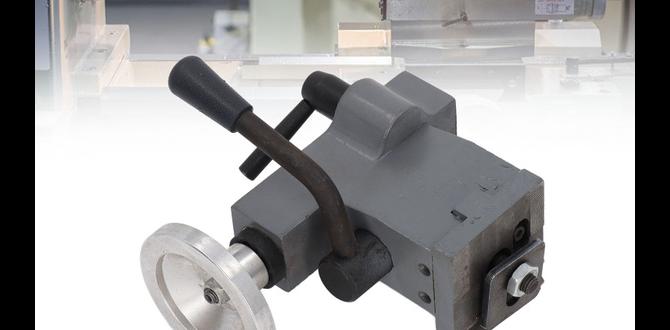

Key parts and their functions. Importance of each component in maintenance.CNC metal lathes rely on several key components to function properly. Each part plays a crucial role, much like a team at a soccer game. The spindle spins the material, while the tool post holds cutting tools steady. Don’t forget the carriage, which moves the tool back and forth like a robot doing the cha-cha. Regular maintenance of these parts keeps everything running smoothly. A clean machine is a happy machine!

| Component | Function |

|---|---|

| Spindle | Holds and rotates the workpiece. |

| Tool Post | Secures the cutting tools. |

| Carriage | Moves the cutting tool along the workpiece. |

Regular Maintenance Tasks for CNC Retrofits

Daily, weekly, and monthly maintenance checklists. Recommended tools and supplies for upkeep.Keeping your CNC retrofits in top shape is key to avoiding drama at the workbench. Daily tasks include checking oil levels and cleaning dust. Weekly, add a quick look at belts and tool sharpness. Monthly, inspect the motor and rails. Using the right tools makes everything easier. Grab some cloths, lubricants, and a nice precision tool kit. Trust me, a happy lathe is a productive lathe—minus the drama!

| Frequency | Tasks | Recommended Tools |

|---|---|---|

| Daily | Check oil, clean dust | Cloths, lubricant |

| Weekly | Inspect belts, check tool sharpness | Wrenches, sharpener |

| Monthly | Examine motor, inspect rails | Precision tool kit, cleaning supplies |

Troubleshooting Common Issues in CNC Metal Lathes

Identifying common mechanical and software problems. Best practices for troubleshooting and repairs.Troubleshooting CNC metal lathes can feel like finding a needle in a haystack. Common issues often include mechanical hiccups, like vibrations, or software glitches that leave you scratching your head. But don’t panic! Start with simple checks. Look for loose parts or faulty connections. Always remember, if a machine starts acting weird, it might need a little love—or just a good restart! Here’s a handy table with quick tips:

| Issue | Potential Cause | Solution |

|---|---|---|

| Vibrations | Loose components | Tighten connections |

| Software errors | Glitches | Restart software |

| Unusual noise | Worn parts | Inspect and replace |

These best practices will help you tackle issues like a pro. Keep your tools handy and your humor close. After all, sometimes a little laugh can keep you from losing your mind over a lumpy bolt!

Best Practices for Extended Lathe Lifespan

Techniques to enhance machine durability. Importance of proper usage techniques.To keep your lathe running well, use it correctly. Follow these tips for a long-lasting machine:

- Clean it often to remove dust and chips.

- Lubricate moving parts regularly for smooth operation.

- Adjust settings carefully to avoid extra wear.

- Inspect it for problems before starting.

Taking breaks can help too. Overworking your lathe can cause stress and damage. Remember, the way you use your lathe affects how long it lasts.

How can proper usage techniques extend lathe lifespan?

Proper usage techniques prevent wear and tear, ensuring smoother operation. Simple actions like regular cleaning and maintenance keep your lathe in top shape.

Upgrading and Implementing New Technologies

Integrating advanced features and controls. Futureproofing your CNC lathe setup.New technology is exciting! Upgrading your CNC lathe helps with speed and accuracy. By adding advanced features, you make work easier. Think of tools that improve control. They can save time and mistakes. This upgrade can protect your machine’s future, too. Futureproofing keeps your setup relevant. You won’t need to replace everything later. Oh, and keep up with the trends! Here’s how:

- Install updated software for easy use.

- Add sensors for better monitoring.

- Use smart controls for easy adjustments.

How does upgrading improve a CNC lathe?

Upgrading a CNC lathe can boost performance, increase quality, and reduce downtime. Features like automation save time, while smart controls help in making precise adjustments. You get better results without extra effort.

Maintaining Software and Control Systems

Importance of software updates and backups. Tips for managing control system errors.Keeping your software updated is like feeding your CNC machine its morning coffee. Without it, things can get sluggish or even break down. Regular updates fix bugs and add new features. Always remember to create a backup. It’s like taking a snapshot of your machine’s brain. You’ll thank yourself later if something goes wrong!

Control system errors can feel like finding a needle in a haystack. To manage them, keep a troubleshooting guide handy. Note error codes and potential fixes. It’s like having a superhero sidekick when things get tricky. Here’s a quick reference table:

| Error Code | Suggested Fix |

|---|---|

| 101 | Restart system |

| 202 | Check connections |

| 303 | Update software |

With the right maintenance, you’ll keep your lathe running smoother than a freshly greased wheel! Remember, a happy machine makes for happy projects.

Safety Considerations in CNC Maintenance

Essential safety precautions during maintenance. Personal protective equipment (PPE) recommendations.Keeping safe during CNC maintenance is super important. First, always wear appropriate personal protective equipment (PPE). This means safety goggles, gloves, and ear protection—because noisy machines can scare your eardrums! Add a catchy helmet to the mix, and you’ll look like a CNC superhero.

| PPE Item | Purpose |

|---|---|

| Safety Goggles | Protects eyes from flying debris |

| Gloves | Prevents cuts and bruises |

| Ear Protection | Reduces loud noises |

| Helmet | Protects head from falls |

Additionally, always keep your workspace clean. A tidy area is less likely to trip you up—literally! So, be safe, gear up, and make maintenance fun. Remember: Safety first, machine magic after!

Conclusion

In conclusion, a maintenance guide for a metal lathe CNC retrofit helps you keep your machines running well. Regular checks and proper cleaning extend their life. You can improve performance by learning about upgrades. We encourage you to explore more resources on maintenance and retrofitting. Taking these steps will make your lathe work better and last longer!FAQs

Sure! Here Are Five Related Questions On The Topic Of Maintenance For A Metal Lathe Cnc Retrofit:To keep your metal lathe CNC (Computer Numerical Control) running well, we need to do regular checks. First, we should clean it often to remove dust and chips. Next, we check the oil levels to keep everything moving smoothly. Also, we need to tighten any loose parts so nothing falls apart. Finally, we should inspect the cables and wires to make sure they aren’t damaged.

Sure! Please provide the question you’d like me to answer.

What Are The Essential Maintenance Tasks To Ensure The Longevity Of A Retrofitted Cnc Metal Lathe?To keep your retrofitted CNC metal lathe working well, you should do a few important tasks. First, clean it often to remove dust and metal shavings. Next, check and change the oil to keep parts moving smoothly. You also need to make sure the belts and screws are tight. Finally, keep an eye on the machine for any strange sounds or problems.

How Often Should Lubricant Be Applied And What Type Is Recommended For Different Components Of A Cnc Lathe?You should apply lubricant to a CNC lathe about once a week. For the ways and rails, use a special oil called way oil. For the ball screws, a light grease works well. Always check the machine’s manual for specific recommendations. This keeps the lathe running smoothly!

What Diagnostic Tools Or Software Are Useful For Monitoring The Performance And Maintenance Of A Retrofitted Cnc Lathe?To monitor a retrofitted CNC (Computer Numerical Control) lathe, you can use several helpful tools. One useful tool is a performance monitoring software. This software tracks how well the lathe is working. Another tool is vibration analysis software, which checks for unusual movements. You can also use temperature sensors to ensure everything stays cool. These tools help keep your lathe in good shape and running smoothly.

How Can You Identify And Troubleshoot Common Issues That May Arise In A Cnc Lathe Retrofit System?To find problems in a CNC lathe retrofit system, you can start by checking the connections. Make sure all wires are plugged in tightly. Next, look for error messages on the screen. If the machine isn’t moving right, we can check the settings and make sure they match what we need. Finally, testing each part one by one helps us find what’s wrong.

What Safety Precautions Should Be Taken During The Maintenance Of A Cnc Lathe Retrofit Project?When we work on a CNC lathe (a machine that shapes metal), we should be very careful. First, always wear safety goggles to protect your eyes. Next, make sure the machine is turned off before you touch anything. We should also use gloves to keep our hands safe. Finally, be sure to keep the work area clean to avoid tripping or accidents.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Maintenance For A Metal Lathe Cnc Retrofit: “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe CNC (Computer Numerical Control) running well, we need to do regular checks. First, we should clean it often to remove dust and chips. Next, we check the oil levels to keep everything moving smoothly. Also, we need to tighten any loose parts so nothing falls apart. Finally, we should inspect the cables and wires to make sure they aren’t damaged.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Maintenance Tasks To Ensure The Longevity Of A Retrofitted Cnc Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your retrofitted CNC metal lathe working well, you should do a few important tasks. First, clean it often to remove dust and metal shavings. Next, check and change the oil to keep parts moving smoothly. You also need to make sure the belts and screws are tight. Finally, keep an eye on the machine for any strange sounds or problems.”}},{“@type”: “Question”,”name”: “How Often Should Lubricant Be Applied And What Type Is Recommended For Different Components Of A Cnc Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should apply lubricant to a CNC lathe about once a week. For the ways and rails, use a special oil called way oil. For the ball screws, a light grease works well. Always check the machine’s manual for specific recommendations. This keeps the lathe running smoothly!”}},{“@type”: “Question”,”name”: “What Diagnostic Tools Or Software Are Useful For Monitoring The Performance And Maintenance Of A Retrofitted Cnc Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To monitor a retrofitted CNC (Computer Numerical Control) lathe, you can use several helpful tools. One useful tool is a performance monitoring software. This software tracks how well the lathe is working. Another tool is vibration analysis software, which checks for unusual movements. You can also use temperature sensors to ensure everything stays cool. These tools help keep your lathe in good shape and running smoothly.”}},{“@type”: “Question”,”name”: “How Can You Identify And Troubleshoot Common Issues That May Arise In A Cnc Lathe Retrofit System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find problems in a CNC lathe retrofit system, you can start by checking the connections. Make sure all wires are plugged in tightly. Next, look for error messages on the screen. If the machine isn’t moving right, we can check the settings and make sure they match what we need. Finally, testing each part one by one helps us find what’s wrong.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken During The Maintenance Of A Cnc Lathe Retrofit Project?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we work on a CNC lathe (a machine that shapes metal), we should be very careful. First, always wear safety goggles to protect your eyes. Next, make sure the machine is turned off before you touch anything. We should also use gloves to keep our hands safe. Finally, be sure to keep the work area clean to avoid tripping or accidents.”}}]}