Have you ever wondered how to keep your metal lathe working perfectly? A metal lathe is a powerful tool in many workshops. Yet, one small part can cause big problems: the foot brake. This simple device is crucial for your safety and control. What happens when it stops working?

Imagine trying to stop a spinning lathe without a functioning brake. It sounds scary, right? A well-maintained foot brake ensures you can stop your machine safely and quickly. But how do you maintain it? That’s where our guide comes in.

In this article, we’ll dive into the maintenance guide for the metal lathe foot brake. We’ll show you easy steps to keep it in top shape. You don’t need to be a mechanic to follow these tips. Just a little care can go a long way!

So, are you ready to learn how to ensure your foot brake works every time? Let’s get started!

Maintenance Guide For Metal Lathe Foot Brake: Essential Tips

Maintenance Guide for Metal Lathe Foot Brake

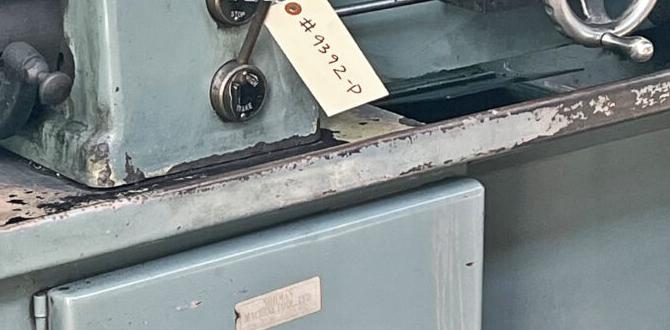

Keeping a metal lathe’s foot brake in top shape is vital for safe operation. Regularly check for wear and tear. Did you know a well-maintained brake can prevent accidents? Ensure all parts are clean and lubricated. Be sure to adjust the brake tension if needed. A simple inspection can save you money and keep your projects on track. With just a few minutes of care, you can make your lathe work easier and safer.Understanding the Metal Lathe Foot Brake

Definition and function of the foot brake in metal lathes. Importance of maintaining the foot brake for safety and performance.A metal lathe foot brake is an important tool that helps stop the lathe quickly and safely. It works by using your foot to activate the brake, which slows down the machine. Keeping the foot brake in good shape is essential for safety. A well-maintained brake ensures you can stop the machine instantly. Regular checks help avoid accidents and keep everything running smoothly.

Why is it important to maintain the foot brake?

Maintaining the foot brake is crucial for both safety and performance. Regular care can prevent injuries and ensure the lathe works as it should. Check for any signs of wear and test it often for smooth operation.

Key Points:

- Stops the lathe quickly.

- Prevents accidents.

- Ensures smooth operation.

Common Issues with Metal Lathe Foot Brakes

Signs of wear and failure in foot brakes. Common problems that can occur due to neglect.Foot brakes are key parts of metal lathes. Over time, they can wear out. Signs of this include:

- Squeaking or grinding noises

- Sluggish or unresponsive movement

- Loose or broken parts

Neglecting to maintain foot brakes can lead to common problems. These may include:

- Increased safety risks

- Higher repair costs

- Reduced machine efficiency

Taking care of your foot brake can help avoid these issues.

What are the signs of foot brake failure?

Some signs include unusual noises, poor response, and visible damage.

Essential Tools and Materials for Maintenance

List of tools required for foot brake maintenance. Recommended lubricants and replacement parts.Taking care of your metal lathe’s foot brake is important. You need some tools and supplies to help you. Here’s a list to get you started:

- Wrench set

- Screwdriver set

- Cleaning rag

- Grease

- Oil can

- Replacement parts

For lubricants, use:

- Machine oil

- Lithium grease

Keep these items handy for smooth operation!

What tools do I need for foot brake maintenance?

You need several tools for foot brake maintenance. Wrenches, screwdrivers, and cleaning rags are essential. Don’t forget lubricants like machine oil and lithium grease. Replacement parts are also crucial for repairs!

Step-by-Step Maintenance Procedures

Premaintenance safety checks. Detailed process for inspecting the foot brake assembly.Safety checks are crucial before diving into maintenance. Always turn off the machine and unplug it first. Check for any loose parts and make sure the floor is clear—no one wants to trip while checking brakes! For the foot brake assembly, inspect the pedal and springs. Make sure they move freely and don’t squeak like a hungry mouse. A quick visual check can save you from bigger problems later!

| Step | Action | Notes |

|---|---|---|

| 1 | Turn off & unplug machine | Safety first! |

| 2 | Inspect foot pedal | Look for cracks or damage |

| 3 | Check springs | Ensure smooth movement |

| 4 | Clear work area | No tripping hazards! |

Adjusting the Foot Brake for Optimal Performance

Techniques for adjusting brake tension and responsiveness. How to align the brake mechanism correctly.Getting the foot brake feeling just right is key for smooth operation. Start by checking the brake tension; it shouldn’t be too loose or too tight. Adjust it so the brake engages with a little push. Next, make sure everything is aligned. An off-kilter brake can throw a wrench in your plans, literally! Use a screwdriver to check the alignment and fix it if needed. If everything is right, your lathes won’t just stop; they’ll stop with style!

| Adjustment Technique | Steps |

|---|---|

| Brake Tension | Check for tightness, then adjust to feel right. |

| Mechanism Alignment | Align all parts, ensuring straight and true. |

Preventative Maintenance Tips

Regular maintenance schedule and checklists. Best practices to extend the lifespan of the foot brake.Keeping your metal lathe’s foot brake in top shape is crucial. Regularly check it to avoid surprises during work. Create a simple maintenance schedule. For example, inspect the brake every month. Check the strength and responsiveness as well. Here’s a quick checklist for you:

| Task | Frequency |

|---|---|

| Inspect brake pad | Monthly |

| Clean brake area | Weekly |

| Lubricate parts | Every 3 months |

Following these best practices can help extend your foot brake’s life. A happy foot brake means a happy you! After all, it’s much better to prevent issues than to stomp around in frustration!

Troubleshooting Common Problems

How to diagnose brake issues based on symptoms. Solutions for the most frequent foot brake malfunctions.Foot brakes can be tricky sometimes, just like trying to catch a slippery fish! If your brake isn’t working, pay attention to what it does. Is it sticking or making a strange noise? These signs can help you figure out the problem. Here’s a quick guide to troubleshoot common brake problems:

| Symptom | Possible Issue | Solution |

|---|---|---|

| Brake won’t release | Brake linkage jammed | Check and lubricate the linkage. |

| Brake makes noise | Worn out parts | Inspect for wear and replace as needed. |

| Pedal feels loose | Loose screws | Tighten screws to secure the pedal. |

By understanding these symptoms, you can quickly get your lathe back on track. Remember, always check the simple stuff first—sometimes, it’s just a matter of tightening a screw or two!

Resources for Further Learning

Recommended books and manuals on metal lathe maintenance. Online forums and communities for metalworking enthusiasts.Learning how to take care of your metal lathe is important. Here are some resources that can help:

- Books and Manuals: Look for books that focus on metal lathe maintenance. They often have step-by-step guides and tips.

- Online Communities: Join forums and website groups where metalworking fans share ideas. You can ask questions and get advice.

Using these resources will make your metal lathe experience easier and more enjoyable. Remember, the more you learn, the better you get!

What are the best books for metal lathe maintenance?

Some great options include “Metal Lathe for Beginners” and “The Complete Guide to Lathe Maintenance”. These books give clear instructions.

Conclusion

In summary, a maintenance guide for a metal lathe’s foot brake is crucial for safe operation. Regularly check the brake for wear and ensure it functions properly. This promotes safety and extends your lathe’s life. Always follow the guide’s steps and don’t hesitate to seek help if needed. For more tips, consider reading about lathe maintenance best practices!FAQs

Sure! Here Are Five Related Questions On The Topic Of Maintaining The Foot Brake Of A Metal Lathe:To keep the foot brake of a metal lathe working well, check it often. Make sure it is clean and free of dust or grease. If the brake feels stiff, you might need to oil it a little. Always test the brake after cleaning to see if it works smoothly. Remember, a good brake keeps you safe while working!

Sure! Please ask the question you want me to answer, and I’ll be happy to help.

What Are The Common Signs That The Foot Brake On A Metal Lathe Needs Maintenance Or Repair?You might notice the foot brake on a metal lathe needs help if it feels stiff or hard to press. If you hear strange noises when you press it, that’s another sign. Sometimes, the brake may not stop the lathe quickly. Also, check if the brake pedal is loose or wobbly. If any of these happen, it’s time to get it fixed!

How Often Should The Foot Brake Mechanism Of A Metal Lathe Be Inspected And Serviced?You should check the foot brake on a metal lathe every month. This helps make sure it works well and keeps you safe. If you use the lathe a lot, you can check it more often. Always remember to fix anything that seems wrong. Regular checks keep you working smoothly!

What Specific Lubrication Or Cleaning Procedures Should Be Followed To Ensure The Foot Brake Operates Smoothly?To keep the foot brake working well, you should clean it regularly. Use a soft cloth to wipe off any dirt or dust. You can also spray a little brake cleaner on the moving parts. Then, add some lubricant made for brakes to help them move smoothly. Remember to check the brakes often to make sure they’re working right!

Are There Any Safety Precautions To Consider When Performing Maintenance On The Foot Brake Of A Metal Lathe?Yes, there are safety precautions to take. First, always turn off the lathe before you start. Make sure to unplug it so it won’t accidentally turn on. Wear safety glasses to protect your eyes from dust or small pieces. Keep your hands away from moving parts. Finally, don’t wear loose clothes that could get caught.

What Tools And Replacement Parts Might Be Needed To Troubleshoot And Repair Issues With The Foot Brake System?To fix problems with the foot brake system, you might need a few tools and parts. First, you’ll need a wrench to take off parts. A screwdriver helps to remove screws too. You might also need new brake pads or brake fluid if those are worn out. Always have a flashlight to see better while you work!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Maintaining The Foot Brake Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the foot brake of a metal lathe working well, check it often. Make sure it is clean and free of dust or grease. If the brake feels stiff, you might need to oil it a little. Always test the brake after cleaning to see if it works smoothly. Remember, a good brake keeps you safe while working!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask the question you want me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That The Foot Brake On A Metal Lathe Needs Maintenance Or Repair?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice the foot brake on a metal lathe needs help if it feels stiff or hard to press. If you hear strange noises when you press it, that’s another sign. Sometimes, the brake may not stop the lathe quickly. Also, check if the brake pedal is loose or wobbly. If any of these happen, it’s time to get it fixed!”}},{“@type”: “Question”,”name”: “How Often Should The Foot Brake Mechanism Of A Metal Lathe Be Inspected And Serviced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the foot brake on a metal lathe every month. This helps make sure it works well and keeps you safe. If you use the lathe a lot, you can check it more often. Always remember to fix anything that seems wrong. Regular checks keep you working smoothly!”}},{“@type”: “Question”,”name”: “What Specific Lubrication Or Cleaning Procedures Should Be Followed To Ensure The Foot Brake Operates Smoothly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the foot brake working well, you should clean it regularly. Use a soft cloth to wipe off any dirt or dust. You can also spray a little brake cleaner on the moving parts. Then, add some lubricant made for brakes to help them move smoothly. Remember to check the brakes often to make sure they’re working right!”}},{“@type”: “Question”,”name”: “Are There Any Safety Precautions To Consider When Performing Maintenance On The Foot Brake Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are safety precautions to take. First, always turn off the lathe before you start. Make sure to unplug it so it won’t accidentally turn on. Wear safety glasses to protect your eyes from dust or small pieces. Keep your hands away from moving parts. Finally, don’t wear loose clothes that could get caught.”}},{“@type”: “Question”,”name”: “What Tools And Replacement Parts Might Be Needed To Troubleshoot And Repair Issues With The Foot Brake System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with the foot brake system, you might need a few tools and parts. First, you’ll need a wrench to take off parts. A screwdriver helps to remove screws too. You might also need new brake pads or brake fluid if those are worn out. Always have a flashlight to see better while you work!”}}]}