Have you ever wondered how a metal lathe works? It’s a fascinating machine! The gear train inside plays a crucial role. Without proper maintenance, even the best lathe can fall short of its potential.

Think about it: what happens to your favorite toy if you don’t take care of it? It loses its shine, right? The same goes for your metal lathe. Keeping the gear train in top shape ensures smooth operation and great results.

In this maintenance guide, we’ll explore simple steps to care for your lathe’s gear train. You’ll learn tips that can help you avoid big problems down the line. Plus, you might be surprised by how easy it is to keep everything running smoothly!

So, are you ready to give your lathe the love it deserves? Let’s dive into the world of metal lathe gear train maintenance!

Maintenance Guide For Metal Lathe Gear Train Components

Maintenance Guide for Metal Lathe Gear Train

Keeping your metal lathe’s gear train in top shape is vital for smooth operation. Regular checks can prevent serious issues. Do you know how often you should lubricate the gears? A simple routine can extend their life. Cleaning debris is crucial too; dust can slow down your machine. Fun fact: even tiny specks can cause wear over time! By following basic maintenance steps, you ensure your lathe runs well and lasts longer. Enjoy smoother projects with less hassle!Understanding the Metal Lathe Gear Train

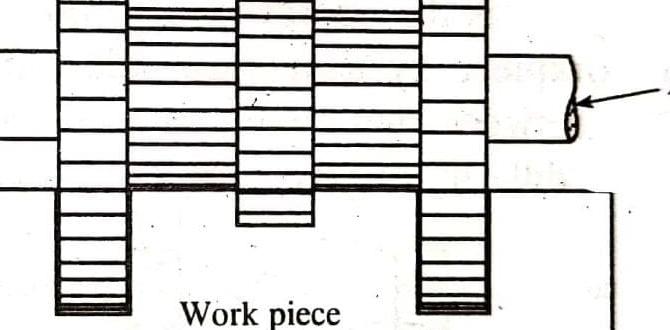

Explanation of the gear train system. Importance of each component in machining processes.The gear train system in a metal lathe is like the secret sauce in a burger—it makes everything work together! Each gear helps control the speed and torque of the machine. Missing one component is like trying to walk without shoes—not very effective! The gears work hard to ensure the cutting tool moves smoothly. Without them, you’d be left with a hunk of metal, not a masterpiece.

| Component | Importance |

|---|---|

| Gears | Control movement and force |

| Spindle | Holds the workpiece steady |

| Drive Belt | Transfers power smoothly |

So, keeping this gear train in tip-top shape is crucial for crafting those perfect pieces. Remember, a happy lathe is a productive lathe!

Common Issues in Gear Train Maintenance

Identification of typical problems (wear, misalignment, etc.). Impacts of neglecting gear train maintenance.Even the toughest metal lathe can have its quirks! Common problems in the gear train include wear and misalignment. Think of wear like your favorite shirt after too many washes—stretched out and a bit rough. Misalignment is like trying to fit a square peg in a round hole; it doesn’t work well! Ignoring these issues can lead to bigger headaches, like unwanted noise or slippage. Trust me, keeping up with maintenance can save you cash and keep your lathe smooth!

| Common Issues | Impact of Neglect |

|---|---|

| Wear and Tear | Decreased Performance |

| Misalignment | Increased Noise |

| Lack of Lubrication | Higher Repair Costs |

Essential Tools for Gear Train Maintenance

List of required tools (wrenches, lubricants, etc.). Recommended brands and qualities.To keep your metal lathe gear train running smoothly, you need the right tools. Here is a list of essential tools:

- Wrenches: Adjustable wrenches are great for tightening parts.

- Lubricants: Use high-quality oils to reduce friction.

- Screwdrivers: A set of various sizes helps with adjustments.

- Cleaning Brushes: Keep the gears clean with stiff-bristle brushes.

- Measuring Tools: Use calipers to ensure proper fit and alignment.

Consider brands like WD-40 for lubricants and Snap-On for wrenches for quality and reliability.

What tools do I need for metal lathe maintenance?

To maintain a metal lathe, you need tools such as: wrenches, lubricants, screwdrivers, cleaning brushes, and measuring tools. Quality brands can make a big difference in how effective your maintenance is.

Step-by-Step Maintenance Procedures

Lubrication techniques for gear components. Cleaning and inspection methods for gear train parts.To keep your lathe running smoothly, proper care of the gear train is key. Here’s how to maintain it:

- Use the right lubricant for the gear parts. This helps reduce friction.

- Clean the gear components regularly. Dirt can cause wear.

- Check for any wear and tear on the gears. Replace if needed.

Regular maintenance will help your metal lathe last longer and work better. Don’t skip it!

What lubricant should I use for my metal lathe?

Use a gear oil that is recommended by the manufacturer. This oil provides the best protection for your lathe gears.

Preventive Measures to Extend Gear Train Life

Best practices for regular maintenance schedules. Adjustments and calibrations to prevent issues.To keep your gear train running smoothly, regular maintenance is key. Here are some best practices:

- Set a maintenance schedule. Check your gear train every month.

- Clean the gears to remove dust and debris that can cause wear.

- Lubricate moving parts to prevent rust and friction.

Make adjustments and calibrations as needed. This helps prevent issues down the road and extends the life of your gear train.

How can I extend the life of my gear train?

Regular checks, proper lubrication, and keeping it clean maximize your gear train’s lifespan.

Troubleshooting Common Gear Train Issues

Diagnostic steps for specific problems. Solutions for resolving common gear train malfunctions.Gear train problems? No worries! First, check for strange noises and loose parts. A noise might mean something is loose or broken. Next, inspect the gears for wear. If you see damage, replace them right away. Don’t forget to check the oil level! Low oil can cause gears to grind. If everything looks good but it still isn’t working right, consult the manual.

| Problem | Diagnostic Steps | Solution |

|---|---|---|

| Strange noises | Listen closely! Look for loose parts. | Tighten or replace parts. |

| Worn gears | Inspect for visible wear. | Replace damaged gears. |

| Grinding sounds | Check oil levels. | Add oil to maintain lubrication. |

Remember, if your gear train is acting stubborn, don’t panic! Maintenance can save you from a meltdown. Happy turning!

Professional Services: When to Seek Help

Signs that indicate a need for professional assistance. How to choose the right technician for gear train issues.It’s important to know when to ask for help. If your metal lathe gear train makes strange noises or does not run smoothly, it is time to seek a professional. Look for these signs:

- Unusual sounds during operation.

- Difficulty changing speeds.

- Visible wear or damage on parts.

Choosing the right technician is key. Look for someone with experience and good reviews. Ask them about similar issues they’ve fixed before.

When should I seek professional help?

If you notice any odd sounds or problems, contact a professional right away. Delaying can cause more damage.

How to choose the right technician?

- Check their qualifications.

- Read client reviews.

- Ask for quotes and compare.

Getting help from the right person is important for your gear train’s health.

Staying Up-to-Date with Gear Train Technology

Innovations in gear train design and materials. Resources for continual learning and updates in gear train maintenance.New ideas keep changing the gear train world. Innovative designs are making machines run smoother and last longer. Materials are being improved too, making them lighter and stronger. To stay updated, you can explore useful resources:

- Online forums for discussions

- YouTube channels with tutorials

- Books about maintenance and technology

By learning from these resources, you can keep your gear train in top shape!

What are good resources for learning about gear train maintenance?

Good resources include online tutorials, forums, and books. These sources help keep you informed about the latest gear train technologies and maintenance tips.

Conclusion

In summary, a maintenance guide for a metal lathe gear train is essential for keeping your machine running smoothly. Regular checks prevent wear and tear. Lubrication ensures gears move freely and efficiently. You can take simple steps to maintain your lathe. For more detailed tips, consider reading user manuals or online resources. Your metal lathe will thank you!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Maintaining The Gear Train Of A Metal Lathe:To keep the gear train of a metal lathe in good shape, you should check it often. Look for dirt or dust and clean it away. Make sure all the parts move smoothly and aren’t rusty. If something seems broken or worn out, it’s best to fix or replace it. This way, your lathe works well for a long time!

Sure! Please give me the question you want to be answered, and I’ll be happy to help.

What Are The Common Signs Of Wear Or Damage In The Gear Train Of A Metal Lathe, And How Can They Be Identified Early?You can spot wear or damage in the gear train of a metal lathe by looking for some signs. First, listen for strange noises while it runs. You might also see uneven cuts in the metal. Check for any loose or wobbly parts. To find these problems early, do regular checks and clean the lathe often.

How Often Should Lubrication Be Applied To The Gears In A Metal Lathe’S Gear Train, And What Type Of Lubricant Is Recommended?You should apply lubrication to the gears of a metal lathe every few weeks. If you use the lathe a lot, check it more often. Use a light oil or grease, like motor oil or machine oil, for the best results. Always make sure to wipe away extra oil to keep it clean.

What Steps Should Be Taken To Properly Clean The Gear Train Components Of A Metal Lathe Without Causing Damage?To clean the gear train components of a metal lathe, first, turn off the machine and unplug it. Next, use a soft brush to gently remove dust and dirt. You can also use a cloth dampened with mild soap and water to clean the parts. Be careful not to use too much water, as it can cause rust. Finally, dry everything well before you put it back together.

How Can One Adjust The Alignment Of The Gear Train To Ensure Smooth Operation And Prevent Gear Slippage?To adjust the alignment of your gear train, first, check if the gears are touching properly. You want them to mesh well without gaps. If they are too far apart or too close, you can move them a bit. Tighten any screws to hold them in place. This helps the gears work smoothly and avoid slipping.

What Preventative Maintenance Practices Can Be Implemented To Extend The Lifespan Of A Metal Lathe’S Gear Train?To keep a metal lathe’s gear train working well, we can do a few simple things. First, we should clean the gears regularly to remove dirt and dust. Next, we can oil the gears to keep them running smoothly. It’s also important to check for any loose parts and tighten them if needed. Finally, we should watch for any strange sounds and fix problems early.