Have you ever wondered how to keep your metal lathe running smoothly? A well-maintained machine can make all the difference. Imagine working on a project and your lathe suddenly stops. Frustrating, right?

The power feed on a metal lathe is crucial for precise work. Like a magic wand, it helps shape metal effortlessly. But just like any tool, it needs care to perform at its best.

In this maintenance guide, we will show you how to care for your metal lathe’s power feed. Regular maintenance can save you time and money in the long run. Did you know that a little attention can prevent big problems?

So, let’s dive into the essentials! With our tips, your lathe will be a trusty ally for years to come. Ready to keep your machine in top shape?

Essential Maintenance Guide For Metal Lathe Power Feed

Maintenance Guide for Metal Lathe Power Feed

Keeping your metal lathe’s power feed in top shape is crucial for smooth operation. Regular checks on gears, lubrication, and belt tension can prevent unexpected breakdowns. Did you know that a little maintenance can extend the life of your machine? Tightening loose screws and cleaning debris can also enhance performance. By following simple steps outlined in this guide, you can ensure your metal lathe works efficiently for years to come.Understanding Metal Lathe Power Feed Systems

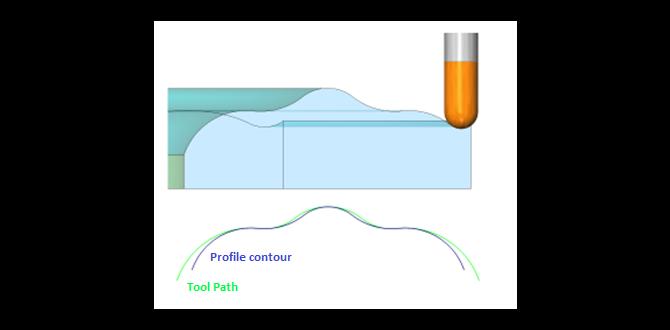

Definition and function of power feed in metal lathes. Benefits of utilizing power feed for machining operations.Power feed systems in metal lathes allow smooth and automatic movement of the machine. This means no more cranking the handle like you’re trying to start a stuck lawnmower! The main job of power feed is to guide the tool precisely along the workpiece, making cuts easier and faster.

Benefits of power feed include efficient machining and reduced operator fatigue. Who wouldn’t want to save energy for that next snack break? Plus, it helps achieve a uniform finish, making your projects look top-notch. Here’s a quick table summarizing the perks:

| Benefit | Description |

|---|---|

| Efficiency | Faster machining reduces production time. |

| Consistency | Uniform cuts improve overall quality. |

| Less Fatigue | Operators save energy for creativity! |

Using a power feed makes everyone’s job a tad easier. Now you can focus on making cool stuff instead of sweating the small stuff!

Routine Maintenance Practices

Daily checks: lubrication and cleaning protocols. Weekly inspections: monitoring wear and tear.Keeping your metal lathe in top shape is key to smooth operations. Start each day with simple checks. Lubricate moving parts and wipe away dust. Think of it as giving your machine a refreshing spa day! On a weekly basis, take a closer look at wear and tear. Check for any loose bolts or worn parts—it’s like your lathe is asking for a little TLC.

| Frequency | Task |

|---|---|

| Daily | Lubricate and clean |

| Weekly | Inspect for wear and tear |

Remember, a well-maintained lathe is a happy lathe! So don’t skip these easy practices. They save time and keep the workshop safe. Your future self will thank you—trust us!

Common Issues and Troubleshooting

Identifying signs of malfunction in power feed systems. Stepbystep troubleshooting for common problems.Power feed systems can sometimes be like mischievous cats—full of surprises! To spot issues, look for clues like strange noises, jerky movements, or if it simply refuses to budge. Identifying these signs early can save you time and money! To troubleshoot, start by checking for loose wires and connections. If the feed doesn’t engage, inspect the switches. Don’t forget to keep the gears greased! Here’s a handy table to help you with common problems:

| Problem | Possible Cause | Solution |

|---|---|---|

| No movement | Loose wiring | Check and secure all connections |

| Strange noises | Lack of lubrication | Apply grease to moving parts |

| Jerky motion | Worn gears | Replace or repair gears |

Remember, keeping your metal lathe in top shape is like sprinkling fairy dust on your work—everything runs smoother!

Advanced Maintenance Techniques

Techniques for disassembling and reassembling power feed components. Advanced diagnostics: using tools and software for performance analysis.Advanced maintenance of a metal lathe’s power feed can help keep your machine running great. Start by carefully disassembling parts. Use the right tools, and take photos for easy reassembly. This way, you know where everything goes. For diagnostics, modern tools and software can check how well your lathe performs. Regular checks help you find issues before they become big problems.

How can I diagnose performance issues in my lathe?

You can diagnose performance issues by using specialized tools that measure speed, vibrations, and power usage. These tools can spot problems early, saving you time and money.

Tips for Disassembling and Diagnosing:

- Use the right screwdriver and wrenches.

- Label each part when you take it apart.

- Use software for performance checks.

Safety Precautions During Maintenance

Essential safety measures to prevent accidents. Personal protective equipment (PPE) recommendations.Safe maintenance of metal lathes is super important. Follow these simple rules to keep accidents away:

- Always wear proper Personal Protective Equipment (PPE).

- Use safety goggles to protect your eyes.

- Wear gloves to shield your hands from sharp edges.

- Protect your ears if using loud machines.

- Keep hair tied back and wear snug clothing.

Remember, safety comes first! It helps you work better and avoids injuries.

What are important safety measures for maintenance?

Wear safety goggles, gloves, and ear protection to avoid accidents during maintenance.

PPE recommendations

- Safety goggles

- Heavy-duty gloves

- Ear protection

- Proper footwear

Tools and Supplies Needed for Maintenance

List of essential tools for effective maintenance. Recommended lubricants and replacement parts.Keeping your metal lathe in top shape requires a few handy tools and supplies. First off, grab a trusty wrench set, as you’ll need them for tightening parts. Don’t forget a screwdriver for those pesky screws that love to play hide and seek! A clean cloth is a must for dusting off. Lubricants are like magic potions for your machine. Use machine oil to keep everything running smoothly. As for parts, ensure you have replacement belts and bushings on hand, just in case they need a little TLC. Here’s a quick reference:

| Tool/Supply | Purpose |

|---|---|

| Wrench Set | Tightening Parts |

| Screwdriver | Fixing Screws |

| Clean Cloth | Dusting |

| Machine Oil | Lubrication |

| Replacement Belts | For Updates |

| Bushings | Emergency Replacements |

Now you’re ready to tackle maintenance like a pro, and your lathe will thank you with smooth operations!

Upgrading Your Metal Lathe Power Feed

When to consider upgrades or replacements. Benefits of modern power feed systems.Upgrading your metal lathe power feed can boost your workshop’s productivity. Think about an upgrade when your machine starts to feel sluggish, or if you tire of cranking the handwheels like your granddad! Modern power feed systems are smoother and more efficient. They save time and effort, letting you focus on your projects rather than fighting your tools. Plus, they often come with cool features like digital readouts. Who knew metalworking could have a touch of technology and fun?

| When to Upgrade | Benefits of Modern Systems |

|---|---|

| Sluggish performance | Smoother operation |

| Excessive wear and tear | Increased efficiency |

| Lack of advanced features | Modern tech perks |

Upgrading can turn your old metal beast into a fine-tuned machine. Don’t be afraid to embrace new technology; your lathe will thank you!

Resources for Further Learning

Recommended books, online courses, and forums. Manufacturer guides and specifications for specific models.Learning more about metal lathe maintenance can be a piece of cake! Start with **recommended books** like “The Complete Guide to Lathes” that simplifies everything. Want to unlock new skills? Try **online courses** that offer step-by-step videos; they might even feature a cat on a lathe for some laughs! Join friendly **forums** to swap tips with fellow hobbyists. Don’t forget to check the **manufacturer guides** for your specific model—they’re like treasure maps for your lathe. Here’s a quick look:

| Resource | Type |

|---|---|

| The Complete Guide to Lathes | Book |

| Metalworking Mastery Course | Online Course |

| Lathe Lovers Forum | Forum |

| Your Model’s Manual | Manufacturer Guide |

Conclusion

In conclusion, a maintenance guide for metal lathe power feeds helps you keep your tools in great shape. Regular checks prevent issues and ensure safety. You should clean, lubricate, and adjust parts often. By following these steps, you can extend your lathe’s life and improve performance. For more detailed tips, consider reading about specific maintenance practices. Happy turning!FAQs

Sure! Here Are Five Related Questions About The Maintenance Of A Metal Lathe Power Feed:To keep a metal lathe power feed working well, we should check the oil regularly. Oil helps the machine run smoothly. We also need to clean it often to remove dust and chips. If we notice any strange noises, we should look for problems right away. Finally, don’t forget to tighten loose parts to keep everything safe!

Sure! Please provide me with the question you’d like answered.

What Are The Essential Maintenance Tasks For Ensuring The Optimal Performance Of A Metal Lathe’S Power Feed System?To keep your metal lathe’s power feed system working well, you should do a few simple tasks. First, check the oil level and add more if it’s low. Then, clean any dirt or chips from the gears and belts. Also, look for loose screws and tighten them if needed. Finally, make sure the feed mechanism moves smoothly without sticking.

How Often Should The Lubricants In The Power Feed Mechanism Be Checked And Replaced?You should check the lubricants in the power feed mechanism every month. If they look dirty or thick, it’s time to replace them. Fresh lubricants help machines work better. We need to keep our tools in good shape!

What Signs Indicate That The Power Feed System Of A Metal Lathe Needs Adjustment Or Repair?You might see a few signs that tell us the power feed system on a metal lathe needs fixing. If the lathe makes strange noises, that’s a clue. You may also notice the feed isn’t smooth and feels bumpy. If it suddenly stops working, it definitely needs our attention. Finally, if any parts look worn or damaged, we should check and fix them right away.

How Can Debris And Contaminants In The Power Feed Mechanism Be Effectively Removed?To clean debris and dirt from the power feed mechanism, you can use a soft brush or a cloth. First, make sure the machine is off and safe. Then, gently scrub or wipe away the dirt you see. If there are stubborn spots, you can use some mild soap and water. Keep everything dry once you’re done!

What Tools And Supplies Are Necessary For Performing Routine Maintenance On A Metal Lathe’S Power Feed?To take care of a metal lathe’s power feed, you need a few simple tools. First, grab a wrench to tighten bolts. You also need a screwdriver to adjust small parts. A brush helps clean dirt and dust away. Lastly, keep some lubricating oil handy to keep everything running smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About The Maintenance Of A Metal Lathe Power Feed:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe power feed working well, we should check the oil regularly. Oil helps the machine run smoothly. We also need to clean it often to remove dust and chips. If we notice any strange noises, we should look for problems right away. Finally, don’t forget to tighten loose parts to keep everything safe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like answered.”}},{“@type”: “Question”,”name”: “What Are The Essential Maintenance Tasks For Ensuring The Optimal Performance Of A Metal Lathe’S Power Feed System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe’s power feed system working well, you should do a few simple tasks. First, check the oil level and add more if it’s low. Then, clean any dirt or chips from the gears and belts. Also, look for loose screws and tighten them if needed. Finally, make sure the feed mechanism moves smoothly without sticking.”}},{“@type”: “Question”,”name”: “How Often Should The Lubricants In The Power Feed Mechanism Be Checked And Replaced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the lubricants in the power feed mechanism every month. If they look dirty or thick, it’s time to replace them. Fresh lubricants help machines work better. We need to keep our tools in good shape!”}},{“@type”: “Question”,”name”: “What Signs Indicate That The Power Feed System Of A Metal Lathe Needs Adjustment Or Repair?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might see a few signs that tell us the power feed system on a metal lathe needs fixing. If the lathe makes strange noises, that’s a clue. You may also notice the feed isn’t smooth and feels bumpy. If it suddenly stops working, it definitely needs our attention. Finally, if any parts look worn or damaged, we should check and fix them right away.”}},{“@type”: “Question”,”name”: “How Can Debris And Contaminants In The Power Feed Mechanism Be Effectively Removed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean debris and dirt from the power feed mechanism, you can use a soft brush or a cloth. First, make sure the machine is off and safe. Then, gently scrub or wipe away the dirt you see. If there are stubborn spots, you can use some mild soap and water. Keep everything dry once you’re done!”}},{“@type”: “Question”,”name”: “What Tools And Supplies Are Necessary For Performing Routine Maintenance On A Metal Lathe’S Power Feed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of a metal lathe’s power feed, you need a few simple tools. First, grab a wrench to tighten bolts. You also need a screwdriver to adjust small parts. A brush helps clean dirt and dust away. Lastly, keep some lubricating oil handy to keep everything running smoothly.”}}]}