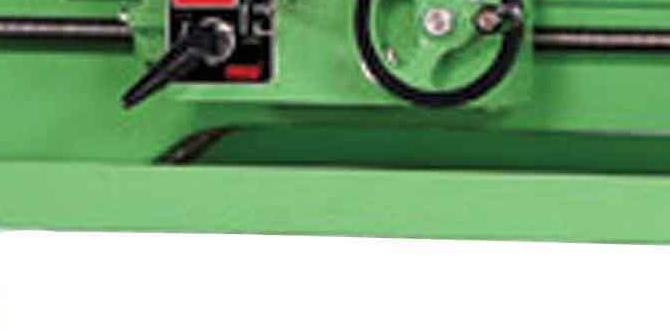

Maintenance Guide: Metal Lathe Torque Tips And Techniques Metal Lathes Are Essential Tools In Machining And Fabrication, Allowing For Precision Shaping And Cutting Of Various Materials. Proper Maintenance Is Crucial For Ensuring Optimal Performance And Longevity Of Your Metal Lathe, Particularly When It Comes To Torque Settings. In This Guide, We Will Delve Into Maintenance Routines And Torque Calibration, Providing You With The Knowledge Needed To Keep Your Metal Lathe In Top Condition. Importance Of Torque In Metal Lathe Maintenance Torque Plays A Vital Role In The Operation Of A Metal Lathe. It Is The Force That Enables The Lathe’S Spindle And Tooling To Perform Effectively. Incorrect Torque Settings Can Lead To Inefficiencies, Tool Wear, And Even Equipment Damage. Regular Maintenance And Recalibration Of Torque Are Necessary To Ensure Precise Operation. Routine Maintenance Checklist 1. **Inspect And Clean The Lathe:** Regularly Check For Debris, Chips, And Coolant Residue. A Clean Workspace Prevents Unexpected Issues And Promotes Accurate Machining. 2. **Check Torque Specifications:** Always Refer To The Manufacturer’S Manual To Understand The Necessary Torque Specifications For Various Components, Including Screws, Bolts, And Tool Mounts. 3. **Lubrication:** Ensure That All Moving Parts Are Well-Lubricated. This Minimizes Friction And Helps Maintain The Required Torque Levels As The Lathe Operates. 4. **Belt Tension Adjustment:** Check The Tension On The Drive Belts And Adjust Accordingly. Proper Tension Ensures Smooth Operation And The Necessary Torque Transfer From The Motor To The Spindle. 5. **Monitor Tool Condition:** Dull Or Damaged Tools Can Increase The Load On The Lathe, Affecting Torque. Regularly Inspect Cutting Tools And Replace Them As Needed. Calibration Of Torque Settings The Calibration Of Torque Settings Is A Critical Aspect Of Metal Lathe Maintenance. Here’S How To Ensure That Your Lathe Is Correctly Calibrated: 1. **Use A Torque Wrench:** Invest In A Quality Torque Wrench For Accurate Settings. This Tool Is Essential When Adjusting Fasteners And Clamps. 2. **Follow Manufacturer Guidelines:** Reference The Lathe’S Manual For Specific Torque Requirements On Each Component. 3. **Conduct Regular Checks:** Establish A Schedule For Checking And Recalibrating Torque Settings To Avoid Discrepancies Over Time. 4. **Document Adjustments:** Keep A Log Of All Torque Settings And Adjustments Made During Maintenance For Future Reference And Accountability. Addressing Common Torque-Related Issues Over Time, You May Encounter Some Common Issues Related To Torque On A Metal Lathe. Here Are A Few To Watch For: – **Vibration:** Excessive Vibration Can Signal Low Torque On Key Fasteners. Check All Mounting Bolts And Re-Torque As Necessary. – **Inaccurate Cuts:** If Your Lathe Is Not Producing Precise Cuts, It May Be A Sign Of Improper Torque On The Tool Holder Or Cutting Tool. – **Increased Wear:** Components That Are Under Or Over-Torqued Can Lead To Increased Wear And Tear. Regularly Checking Torque Can Help Prevent This. Conclusion Maintaining The Correct Torque Settings On Your Metal Lathe Is Crucial For Ensuring Efficient Operation And Longevity Of The Machine. By Adhering To A Regular Maintenance Routine, Utilizing Proper Tools, And Addressing Common Issues Proactively, You Can Extend The Life Of Your Lathe And Enhance Its Performance. Always Prioritize Following Manufacturer Recommendations To Achieve The Best Results.

Maintenance Guide for Metal Lathe Torque

Maintaining your metal lathe is crucial for its performance. Proper torque settings can prevent wear and tear. Did you know that regular checks can add years to your lathe’s life? Learn to adjust the torque to avoid costly repairs. Use tools like a torque wrench to ensure accuracy. Spotting issues early keeps your projects on track. Why risk a breakdown when simple routines can safeguard your equipment? Your lathe will thank you!Understanding Metal Lathe Torque

Definition of torque in the context of metal lathes. Importance of torque in maintaining lathe performance.Torque is the turning force that helps metal lathes work properly. It’s like a strong twist that makes things spin. Without the right torque, lathes can struggle or break. High torque keeps the lathe running smooth. Proper torque also helps get clean cuts on the metal. This is important for any project. When maintaining the lathe, checking torque is a must. It helps keep the machine safe and in good shape.

What is the role of torque in metal lathe maintenance?

The right torque ensures smooth operation and extends the lathe’s life. Proper torque helps avoid damage and ensures precise cuts, making every project easier and better.

Key Factors of Torque Importance

- Improves cutting performance

- Reduces wear and tear

- Helps maintain accuracy

- Increases safety during use

Essential Maintenance Tools and Supplies

List of necessary tools for torque maintenance. Recommended lubricants and cleaning agents.To keep your metal lathe running smoothly, having the right tools and supplies is crucial. These include a torque wrench, oil cans, and cleaning brushes. With these tools in your toolbox, you’ll be ready for anything. Your lathe will appreciate the regular love it receives!

| Essential Tool | Purpose |

|---|---|

| Torque Wrench | Checks and sets torque |

| Lubricating Oil | Reduces friction, keeps parts moving |

| Cleaning Brush | Removes chips and debris |

For lubricants, choose a high-quality oil that won’t break the bank! Look for options labeled specifically for machinery use. Remember, a clean lathe is a happy lathe, so grab your favorite cleaning agent too. It’s like a spa day but for machines!

Torque Specifications for Metal Lathes

How to find manufacturer torque specifications. Importance of adhering to specified torque values.Finding the right torque specifications for your metal lathe is simple. Check the manufacturer’s manual; it’s like a treasure map for your machine! Each lathe has its own unique torque values, so follow them closely. Why? Because using the wrong torque is like trying to bake a cake without following the recipe — you might end up with a disaster! Here’s a quick look at some typical specifications:

| Part | Torque (ft-lbs) |

|---|---|

| Spindle Nut | 20-30 |

| Tool Holder | 10-15 |

Sticking to these specified torque values keeps your lathe running smoothly. Remember, a happy lathe means fewer headaches for you!

Regular Maintenance Tasks for Optimal Torque

Scheduled checks and adjustments needed for torque. Procedures for tightening and calibrating lathe components.Keeping your metal lathe in tip-top shape is like feeding a hungry pet. It needs regular attention! Scheduled checks help keep the torque just right. You want to ensure all parts are snug, so they don’t wiggle like jelly. Tighten bolts and calibrate components regularly—that’s the secret sauce to effective lathe performance.

| Task | Frequency |

|---|---|

| Tightening bolts | Weekly |

| Calibrating torque settings | Monthly |

| Lubricating moving parts | Every 500 hours |

Remember, a well-maintained lathe is a happy lathe! Regular tasks make sure your lathe runs smoothly and minimizes surprises. Think of it as giving your machine a pep talk before it starts a big project!

Troubleshooting Torque-Related Issues

Common problems caused by improper torque. Stepbystep guide to diagnose and resolve torque issues.Torque is like the Goldilocks of your metal lathe. Too little or too much can cause common problems. These include parts not fitting right, screws coming loose, or even your machine stalling like it saw a ghost! To troubleshoot, follow these simple steps:

| Problem | Action |

|---|---|

| Loose screws | Check the torque settings and adjust as needed. |

| Poor cuts | Increase torque gradually until the machine runs smoothly. |

| Stalling | Inspect for proper torque on all moving parts. |

Remember, it’s all about balance! Keeping an eye on torque prevents headaches later. Happy lathe-ing!

Best Practices for Maintaining Torque on Metal Lathes

Daily habits to ensure consistent torque maintenance. Recommended maintenance schedules and intervals.To keep your metal lathe running smoothly, develop daily habits. Check the torque settings before each use; it’s like checking your shoelaces before a race! Regularly lubricate parts to ensure they glide like a hot knife through butter. Set a schedule for deeper maintenance: every week for a quick clean, and every month for a thorough check. This way, your lathe will be as happy as a cat in a sunbeam!

| Maintenance Task | Frequency |

|---|---|

| Check torque settings | Daily |

| Lubricate parts | Daily |

| Quick clean | Weekly |

| Deep inspection | Monthly |

These practices help maintain optimal torque. Remember, a well-maintained lathe is like a well-oiled machine—a happy tool makes for happy work!

Upgrading Your Metal Lathe for Better Torque Performance

Modifications to enhance torque efficiency. Potential upgrades for increased longevity and performance.Improving your metal lathe’s torque can make a big difference in its performance. Small changes can help your machine run better and last longer. Consider these modifications:

- Upgrade the motor for more power.

- Install a better belt for less slippage.

- Add a torque converter for smoother operation.

These upgrades can boost efficiency and extend the life of your lathe. A well-maintained tool is key to great projects!

What are some upgrades for metal lathes?

Upgrades for metal lathes include improved motors, better belts, and torque converters. These enhancements can lead to better torque and overall performance.

Case Studies: Successful Maintenance Practices

Examples of effective maintenance routines from various industries. Lessons learned from maintenance failures and their impact on torque reliability.Many industries have found success by following effective maintenance routines. For example, a car manufacturing plant implemented a daily torque check that kept machines running smoothly. The result? Fewer breakdowns and happier workers! However, not all stories are sunshine and rainbows. A company that ignored maintenance notices faced huge repair costs. They learned the hard way: never underestimate the importance of torque. Here’s a recap in the table below:

| Industry | Effective Routine | Impact of Failure |

|---|---|---|

| Automotive | Daily torque checks | Reduced breakdowns |

| Aerospace | Weekly inspections | Increased safety risks |

| Manufacturing | Monthly training sessions | Higher repair costs |

These examples show how smart maintenance practices can save time and money. So, let’s keep that metal lathe running like a well-oiled machine!

Conclusion

In conclusion, understanding torque in your metal lathe is essential for safe and effective operation. Regularly check and adjust torque settings for best results. This helps prevent damage to your lathe and ensures accurate work. We encourage you to create a maintenance guide for your lathe and explore more resources for deeper insights. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Maintenance Guide For Metal Lathe Torque:Sure! A metal lathe is a machine that shapes metal pieces. To keep it working well, you need to check the torque. Torque is how tight the screws and bolts are. If they are too loose, the lathe can break or work badly. So, make sure to tighten everything correctly to help it run smoothly!

Sure! Just ask your question and I’ll do my best to give you a clear and simple answer!

What Is The Recommended Torque Specification For Various Components Of A Metal Lathe During Maintenance?When you take care of a metal lathe, it’s important to know how tight to make the bolts. For most bolts, you should use about 15 to 30 foot-pounds of torque. That means how much strength you use to turn the bolt. Always check your owner’s manual for special parts, as they might need different settings! This helps keep everything working well and safe.

How Can Improper Torque Settings Affect The Performance And Longevity Of A Metal Lathe?If you don’t use the right torque settings on a metal lathe, it can cause problems. The parts might become loose or too tight. This can make the machine work poorly or even break. If parts break, the lathe won’t last as long and you’ll have to fix it more often. So, using the correct torque helps keep everything running smoothly.

What Tools Are Best Suited For Measuring And Applying Torque When Maintaining A Metal Lathe?To measure and apply torque on a metal lathe, you can use a torque wrench. A torque wrench helps you tighten bolts just right. Another useful tool is a torque screwdriver, which is good for smaller screws. Both tools let you know when you’ve used the right amount of force. Always check your tools before starting work!

How Often Should The Torque Specifications Be Checked And Adjusted On A Metal Lathe To Ensure Optimal Performance?You should check the torque settings on your metal lathe often. It’s best to do this every week or whenever you change tools. Make sure the screws are tight but not too tight. This helps the lathe work better and last longer. If you feel something is off, check it right away!

What Are The Common Signs That Indicate A Need For Torque Adjustments On A Metal Lathe?You might need to adjust the torque on a metal lathe if you see some signs. First, if there are strange noises, that’s a clue. Second, if the metal piece isn’t cutting smoothly, it’s time to check. Lastly, if the tool gets stuck or jumps around, we should make adjustments to the torque. Keeping an eye on these signs helps us work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Maintenance Guide For Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine that shapes metal pieces. To keep it working well, you need to check the torque. Torque is how tight the screws and bolts are. If they are too loose, the lathe can break or work badly. So, make sure to tighten everything correctly to help it run smoothly!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question and I’ll do my best to give you a clear and simple answer!”}},{“@type”: “Question”,”name”: “What Is The Recommended Torque Specification For Various Components Of A Metal Lathe During Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you take care of a metal lathe, it’s important to know how tight to make the bolts. For most bolts, you should use about 15 to 30 foot-pounds of torque. That means how much strength you use to turn the bolt. Always check your owner’s manual for special parts, as they might need different settings! This helps keep everything working well and safe.”}},{“@type”: “Question”,”name”: “How Can Improper Torque Settings Affect The Performance And Longevity Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t use the right torque settings on a metal lathe, it can cause problems. The parts might become loose or too tight. This can make the machine work poorly or even break. If parts break, the lathe won’t last as long and you’ll have to fix it more often. So, using the correct torque helps keep everything running smoothly.”}},{“@type”: “Question”,”name”: “What Tools Are Best Suited For Measuring And Applying Torque When Maintaining A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure and apply torque on a metal lathe, you can use a torque wrench. A torque wrench helps you tighten bolts just right. Another useful tool is a torque screwdriver, which is good for smaller screws. Both tools let you know when you’ve used the right amount of force. Always check your tools before starting work!”}},{“@type”: “Question”,”name”: “How Often Should The Torque Specifications Be Checked And Adjusted On A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the torque settings on your metal lathe often. It’s best to do this every week or whenever you change tools. Make sure the screws are tight but not too tight. This helps the lathe work better and last longer. If you feel something is off, check it right away!”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Need For Torque Adjustments On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might need to adjust the torque on a metal lathe if you see some signs. First, if there are strange noises, that’s a clue. Second, if the metal piece isn’t cutting smoothly, it’s time to check. Lastly, if the tool gets stuck or jumps around, we should make adjustments to the torque. Keeping an eye on these signs helps us work better!”}}]}