Have you ever wondered how old machines can become modern marvels? One exciting way is through a manual metal lathe CNC retrofit. This simple process turns a traditional lathe into a high-tech tool. Imagine taking a machine from the past and giving it new life.

Many hobbyists and small businesses want to make their work easier. They turn to CNC to help them create precise parts. A manual metal lathe retrofit makes this possible without needing to buy a brand-new machine.

Did you know that many factories still use older lathes? These machines are strong and reliable. By retrofitting them, users can combine old-school craftsmanship with new technology. This blend of old and new can lead to amazing results.

In the following sections, we will explore how to retrofit these machines. You will learn what parts you need and how to install them. Join us on this journey to discover the world of manual metal lathe CNC retrofit!

Manual Metal Lathe Cnc Retrofit: Transforming Precision Machining

Manual Metal Lathe CNC Retrofit

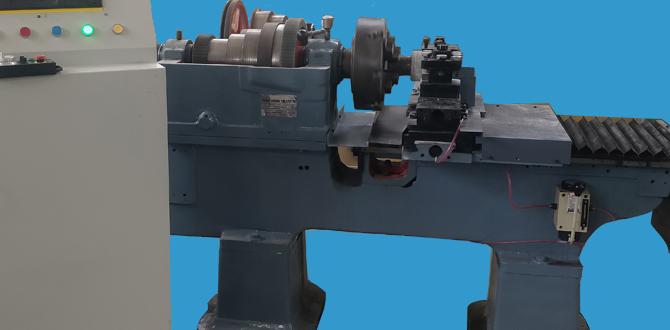

Ever wondered how to modernize an old metal lathe? A CNC retrofit turns your manual lathe into a computer-controlled machine. This upgrade enhances precision and efficiency in your metalworking projects. Imagine completing tasks faster and with greater accuracy! By adding CNC components, you can save time and reduce errors. Retrofitting is often more cost-effective than buying new machines. Curious about how it all works? This transformation opens a world of possibilities for hobbyists and professionals alike!Understanding Manual Metal Lathes

Definition and functionality of manual metal lathes. Key components and mechanics of operation.Manual metal lathes are machines that help shape metal. They turn the metal while tools cut, creating various shapes. Essential parts include the bed, spindle, and carriage. Tools move along the metal to create objects like gears and pipes. These machines are used in shops for different projects. They offer precise control and are great for custom work.

What are the key components of manual metal lathes?

- Bed: The main part that supports everything.

- Spindle: Holds the metal and spins it.

- Carriage: Moves tools along the metal.

The Benefits of CNC Retrofitting

Advantages of converting a manual lathe to CNC. Costeffectiveness compared to purchasing a new CNC machine.Upgrading a manual lathe to CNC brings many benefits. It simplifies work and improves precision. You can achieve complex shapes more easily than before. Overall, it is often cheaper than buying a new CNC machine. This change also extends the life of the old lathe, keeping it useful. Here are some advantages:

- Cost savings: Retrofitting costs less than a new CNC machine.

- Improved accuracy: CNC allows for better precision in tasks.

- Efficiency: Less time is needed to complete jobs.

How Cost-effective is CNC Retrofitting?

CNC retrofitting is usually more affordable than buying a new machine. Retrofitting can save you thousands of dollars. This means budget-friendly long-term use. Many businesses find this option very appealing for upgrading their tools.

Assessing Your Lathe for Retrofit Potential

Criteria to determine if your lathe is suitable for retrofitting. Common limitations and considerations.Knowing if your lathe can be retrofitted is important. Check these criteria:

- Age: Older lathes may have parts that can’t support new tech.

- Condition: Worn-out machines might not work well after upgrading.

- Size: Make sure your lathe can handle new equipment without issues.

- Compatibility: Some lathes don’t fit with modern CNC systems.

Consider these limitations carefully. If your lathe fails to meet these points, retrofitting might not be worth it.

How do I know if my lathe is suitable for retrofit?

Check parts quality, age, and size of your lathe. Look for compatibility with newer CNC designs. Older or damaged lathes may need replacements instead.

Components Required for CNC Retrofitting

Essential hardware for the retrofit process. Recommended software and control systems.To turn your manual metal lathe into a CNC powerhouse, you need some key components. First, grab a high-quality stepper motor or a servo motor for smooth movement. Next, don’t forget a sturdy controller board and the right power supply. Software-wise, look for user-friendly programs like Mach3 or LinuxCNC. They help you direct your machine without needing a PhD in robotics! Below is a simple table of what you’ll need:

| Component | Purpose |

|---|---|

| Stepper/Servo Motor | Controls movement |

| Controller Board | Links software and hardware |

| Power Supply | Powers your setup |

| Software (Mach3/LinuxCNC) | Interface for operation |

With these essentials, you’re on the right track. Remember, CNC retrofitting can turn your manual lathe into a machine that even the Terminator would envy!

The Retrofit Process: Step-by-Step Guide

Preparation and planning for the retrofit. Detailed steps in the installation and setup.Before starting the retrofit, careful planning is important. Gather all your tools and parts. Make a checklist of everything you need. Then, follow these steps for a smooth installation:

- Research your model; find the right CNC kit.

- Remove old parts carefully.

- Install the new hardware according to instructions.

- Test connections and wiring.

- Calibrate the machine for accuracy.

Each step in the process brings your machine closer to being fully automated. Patience and attention to detail make a big difference!

What should I prepare before starting?

Gather tools, parts, and manuals beforehand. Make sure your workspace is clean and safe.

Maintenance and Troubleshooting of Retrofitted CNC Lathes

Regular maintenance practices for longevity. Solutions to common issues faced postretrofit.Keeping your retrofitted CNC lathe in good shape is key for a long life. Regular checks help spot problems early. Here are some maintenance tips:

- Clean the machine often.

- Check oil and coolant levels.

- Tighten loose parts and screws.

- Inspect cables and connections.

Common issues can pop up, like power loss or strange noises. Here’s how to fix them:

- **Check the power supply if your lathe won’t start.**

- **Lubricate moving parts to stop loud sounds.**

- **Adjust the software settings if cuts aren’t smooth.**

Following these steps helps keep your machine running smoothly!

What are some important maintenance tips for retrofitted CNC lathes?

Proper maintenance keeps your CNC lathe running. You should clean it often and check oil levels. That way, your machine will last longer.

Case Studies: Successful Manual to CNC Conversions

Realworld examples of retrofitting projects. Lessons learned and results achieved.Many workshops have successfully switched from manual lathes to CNC systems. One case involved a small machine shop upgrading their manual lathe. They improved their speed and accuracy. Another example is a factory that saved costs by retrofitting old machines. Here are key takeaways:

- Increased Production: Retrofits led to faster work.

- Better Precision: CNC systems ensured high-quality output.

- Cost Savings: Upgrading older machines cut expenses.

These examples proved that a manual metal lathe CNC retrofit can be a smart investment.

What are the benefits of converting manual lathes to CNC?

Converting boosts speed, accuracy, and reduces costs.

Future Trends in CNC Technology and Retrofitting

Innovations in CNC retrofitting. Predictions for the future of manual lathes in CNC applications.Exciting changes are happening in the world of CNC technology. Innovations in retrofitting make older machines smarter and faster. Imagine your manual lathe suddenly becoming a tech wizard! Predictions show that in the future, these manual machines will be the cool sidekicks of advanced CNC systems. They may transform, offering more precision at a fraction of the cost. It’s like turning a rusty old dinosaur into a speedy robot!

| Innovation | Impact |

|---|---|

| Smart sensors | Improve accuracy |

| User-friendly software | Ease of use |

| Energy-efficient motors | Reduce costs |

Conclusion

In conclusion, a manual metal lathe CNC retrofit can upgrade your machinery for better precision and efficiency. You can transform old equipment into advanced tools. This process saves money and extends the life of your lathe. We encourage you to explore retrofit kits or guides online to learn more. Start improving your workshop today and enjoy the benefits!FAQs

Sure! Here Are Five Related Questions On The Topic Of Manual Metal Lathe Cnc Retrofit:Sure! Here are five related questions about turning a manual metal lathe into a CNC (Computer Numerical Control) machine. 1. What is a manual metal lathe? A manual metal lathe is a machine that helps shape metal by rotating it while cutting tools shape it. 2. Why would we want to change it to CNC? We change it to CNC to make it easier and faster to create precise shapes and designs automatically. 3. How does a CNC retrofit work? A CNC retrofit adds new parts, like motors and a computer, to let the machine run on its own. 4. What do we need for the retrofit? You’ll need new motors, a controller, a computer, and software to make the machine work as CNC. 5. Is it hard to do a retrofit? It can be tricky, but with the right tools and instructions, you can definitely do it!

Sure! Just give me the question you’d like me to answer, and I’ll help you with a short response.

What Are The Key Components Required For Retrofitting A Manual Metal Lathe Into A Cnc Machine?To change a manual metal lathe into a CNC machine, you need some important parts. First, you need a CNC controller, which tells the machine what to do. Next, you’ll need a stepper motor or servo motor, which helps move the lathe. You also need a power supply to give energy to the motors. Lastly, add limit switches to keep everything safe.

How Does The Accuracy And Precision Of A Cnc-Retrofitted Lathe Compare To A Fully Cnc Machine?A CNC-retrofitted lathe is an older machine that has been updated with new technology. It can be pretty good, but a fully CNC machine usually works better. The fully CNC machine is more accurate, which means it makes parts that fit perfectly. It’s also more precise, so it can repeat the same job very well every time. You might find that the fully CNC machine produces better results, especially for complex tasks.

What Types Of Control Software Are Commonly Used In Retrofitting Manual Lathes For Cnc Operation?When we change a manual lathe to a CNC (Computer Numeric Control) lathe, we need special software. Popular options include LinuxCNC, Mach3, and GRBL. LinuxCNC is free and works on many machines. Mach3 is easy for beginners to use. GRBL is simple and works with small machines. These programs help us control the lathe using a computer.

What Are The Common Challenges Faced During The Retrofitting Process Of A Manual Metal Lathe?When we retrofit a manual metal lathe, we might face some problems. First, finding the right parts can be tough. Sometimes, the old machine may not work well with new pieces. We also need to make sure everything fits together correctly. Lastly, if we’re not careful, we could make mistakes that would cost money.

How Can You Determine Whether Retrofitting A Manual Lathe Is More Cost-Effective Than Purchasing A New Cnc Lathe?To see if fixing up a manual lathe is cheaper than buying a new CNC lathe, we need to add up costs. First, check how much it will cost to retrofit, which means upgrading the old machine. Then, look at the price of a new CNC lathe. We should also think about how much money we’ll save in the future. If the retrofit costs less and helps you work better, it might be the better choice.