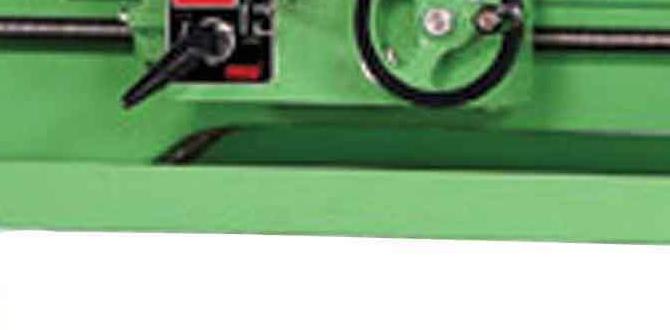

Manual Metal Lathe Compound Rest: A Comprehensive Guide

Understanding the Manual Metal Lathe Compound Rest

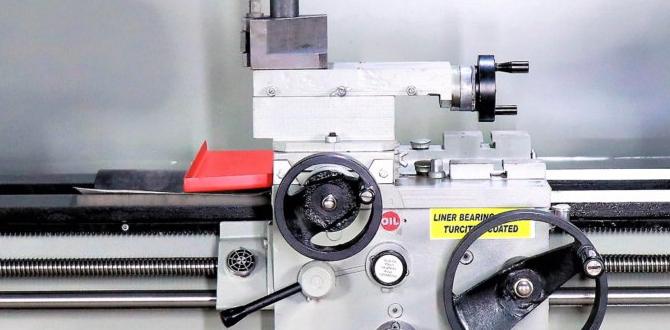

The manual metal lathe compound rest is an essential tool used for precision machining. This part allows for fine adjustments when cutting materials. Imagine you want to create a perfect cylinder. The compound rest helps you tilt and move the cutting tool accurately. Did you know that many experienced machinists rely on this handy feature for detailed work? Knowing how to use a compound rest can make your metalworking projects smooth and successful.What is a Compound Rest?

Definition and purpose of a compound rest in metal lathes. Key components and their functions.A compound rest is an important part of a metal lathe. It helps move the cutting tool smoothly and accurately. This device allows for precise shaping of materials. Key components include:

- Base: Provides stability.

- Cross Slide: Moves side to side for adjustments.

- Swivel Base: Allows angle adjustments for cutting.

- Handwheel: Controls movement easily.

By using the compound rest, you can make skilled cuts on metal pieces. It’s essential for creating things like parts and tools.

What are the benefits of using a compound rest?

Using a compound rest allows for greater precision and control when shaping metal. It helps achieve the desired angles and dimensions.

Importance of a Compound Rest in Metalworking

Role in precision machining and intricate operations. Advantages over fixed tool rests.A compound rest is essential for precise metalworking. It helps machines make accurate cuts and shapes. This tool allows smoother movements, which makes it easier to work on complicated designs. Without it, your work may lack detail and precision.

Compared to fixed tool rests, a compound rest offers these benefits:

- Greater flexibility for different angles.

- Improved control for intricate tasks.

- Enhanced stability during operation.

Having such a tool can lead to better results and higher quality projects.

Why is a compound rest better than a fixed tool rest?

A compound rest provides more flexibility and control. This allows for intricate cutting angles and smoother movements. It makes complicated tasks easier and more accurate.

Common Types of Compound Rests

Description of various types available in the market. Pros and cons of each type.Compound rests come in several types, each offering unique features. First, we have the fixed compound rest. It’s sturdy but lacks movement, which can be limiting. The swivel compound rest can tilt, making it great for tricky angles, but it may wobble sometimes. Then there’s the quick-change compound rest, perfect for fast setups, but it can be pricey. Lastly, the advanced digital compound rest is high-tech with precision, yet you need to charge it, or it might take a nap! Choosing the right one depends on your needs and budget.

| Type | Pros | Cons |

|---|---|---|

| Fixed | Stable | No movement |

| Swivel | Adjustable angles | Can wobble |

| Quick-change | Fast setups | More expensive |

| Digital | High precision | Needs charging |

Features to Look for in a Quality Compound Rest

Essential features that enhance usability and performance. Factors affecting durability and maintenance.Quality matters! A great compound rest should be sturdy and easy to use. Look for robust materials to ensure durability. Smooth movement is a must for precise cuts and less head-scratching. Also, adjustability helps you tackle different tasks, making your projects easier and more fun! Oh, and don’t forget—some features are so fancy, you’ll feel like a wizard at the lathe! Always check how easy it is to maintain, too. After all, nobody wants to babysit their tools!

| Feature | Importance |

|---|---|

| Material Strength | Durability and stability during use |

| Smooth Operation | Improves performance and accuracy |

| Adjustability | Versatility for different projects |

| Maintenance Ease | Simplifies care and upkeep |

Setting Up a Compound Rest on a Manual Metal Lathe

Stepbystep guide to installation. Tips for achieving optimal alignment.Getting your compound rest set up properly gives you control over your metal lathe. First, ensure you have the right tools ready. You’ll need a wrench and a few screws. Next, follow these steps:

| Step | Action |

|---|---|

| 1 | Loosen the screws on the compound rest. |

| 2 | Align it with the cross-slide. |

| 3 | Tighten the screws firmly. |

To achieve optimal alignment, remember to check for even gaps. If all looks good, you’re ready to roll—or should I say spin? If things get wobbly, just adjust a bit more. After all, even the best lathe needs a little TLC sometimes!

Operating Techniques for Using a Compound Rest

Recommended practices for effective usage. Common mistakes to avoid during operation.To use a compound rest effectively, follow these simple practices: keep your tools clean and sharp, and always check your alignment before starting. Common mistakes to avoid include rushing your work and ignoring safety measures. Work slowly and carefully for the best results.

- Ensure correct tool height.

- Secure your workpiece properly.

- Double-check settings before cutting.

What are some tips for using a compound rest?

Take your time and practice regularly. This will help you become familiar with the machine and improve your skills over time. Don’t forget to ask for help if you’re unsure of something!

Maintenance Tips for Longevity of the Compound Rest

Regular maintenance routines. Troubleshooting common issues.Keeping the compound rest in good shape helps it last longer. Regular routines can help you avoid problems later. Here are some tips:

- Clean it often to remove dirt and debris.

- Check for loose parts and tighten them.

- Lubricate moving parts so they work smoothly.

If you run into issues, try these fixes:

- If it sticks, apply more oil.

- If a part is broken, replace it right away.

By following these steps, your compound rest will work better and last longer!

What are the common problems with a compound rest?

Common problems include sticking parts, loose fittings, and wear from lack of lubrication. Regular checks can find these issues early.

Comparing Compound Rests for Different Metal Lathes

Analysis of compatibility with various lathe models. Recommendations based on specific metalworking needs.Not all compound rests fit every lathe like a glove. Each model has its quirks! Compatibility is key. For instance, a small lathe might not handle a big compound rest well. Ensure you check the model before buying. If you need precision for tiny parts, opt for a rest designed for those tasks. Think of it as choosing the right shoes for a school dance—style counts, but comfort is a must!

| Lathe Model | Recommended Compound Rest | Best Use |

|---|---|---|

| Mini Lathe | Compact Rest | Tiny Projects |

| Standard Lathe | Medium Rest | General Use |

| Heavy-Duty Lathe | Large Rest | Big Projects |

Frequently Asked Questions About Compound Rests

Addressing common queries and concerns from users. Expert insights and tips based on user experiences.Many users have questions about using a compound rest. Here are some common ones:

How do I adjust my compound rest?

You can adjust it by loosening the locking screws and turning the handwheel. This helps you set the angle for cutting.

What materials can I use with it?

You can use metals like aluminum, steel, and brass. Each material has its own working properties.

- Master your setup: Always keep it clean and properly aligned.

- Practice: Experiment with different angles to see what works best.

Listening to expert tips can make a big difference. Many users say that a steady hand and careful adjustments lead to the best results.

Conclusion

In conclusion, the manual metal lathe compound rest is essential for precise machining. It helps you adjust angles and positions easily. Understanding how to use it improves your skills. We encourage you to practice with it and explore more resources to deepen your knowledge. The more you learn, the better you’ll become at using lathes effectively. Happy machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of A Manual Metal Lathe Compound Rest:A manual metal lathe compound rest is a part of a machine that helps shape metal. It holds the tool steady as you work. You can move it in different directions for precise cuts. Using it makes your metal projects easier and more accurate. Be careful when using it to stay safe!

Sure! Please provide the question you would like me to answer.

What Is The Primary Function Of The Compound Rest On A Manual Metal Lathe?The compound rest on a manual metal lathe helps you make precise cuts. It can tilt and move side to side. This lets you create different shapes and angles on metal pieces. You can adjust it easily for your work. It makes your projects more accurate!

How Do You Properly Set The Angle Of The Compound Rest For Tapered Machining Operations?To set the angle of the compound rest for making a taper, first measure the angle you need. Use a protractor or angle gauge to help. Next, loosen the angle lock on the compound rest. Tilt the rest to match the angle you measured, then tighten it back. Now you’re ready to start machining the taper!

What Are Some Common Materials Used In The Construction Of A Compound Rest, And How Do They Affect Its Performance?Some common materials for making a compound rest are steel, aluminum, and plastic. Steel is strong and lasts a long time. Aluminum is lighter, making it easier to move, but still strong. Plastic can be less expensive and lighter, but it might not last as long as metal. Each material changes how well the compound rest works.

How Can You Troubleshoot Alignment Issues With The Compound Rest To Ensure Accurate Machining?To fix alignment problems with the compound rest, first look at the screws and make sure they are tight. You can check the angle by using a level or a protractor, which helps you see if it’s straight. If it’s not, you can adjust it by turning the screws gently. Also, make sure the tool you’re using is set correctly. Finally, test your setup by making a small cut and checking if it’s smooth and even.

What Safety Precautions Should Be Taken When Operating A Manual Metal Lathe With A Compound Rest?When you use a manual metal lathe, always wear safety glasses to protect your eyes. Keep your hands away from moving parts and never wear loose clothing. Make sure the tool is set up correctly before starting. You should also keep your work area clean and free from clutter. Finally, never leave the machine running unattended.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of A Manual Metal Lathe Compound Rest:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A manual metal lathe compound rest is a part of a machine that helps shape metal. It holds the tool steady as you work. You can move it in different directions for precise cuts. Using it makes your metal projects easier and more accurate. Be careful when using it to stay safe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Compound Rest On A Manual Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest on a manual metal lathe helps you make precise cuts. It can tilt and move side to side. This lets you create different shapes and angles on metal pieces. You can adjust it easily for your work. It makes your projects more accurate!”}},{“@type”: “Question”,”name”: “How Do You Properly Set The Angle Of The Compound Rest For Tapered Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set the angle of the compound rest for making a taper, first measure the angle you need. Use a protractor or angle gauge to help. Next, loosen the angle lock on the compound rest. Tilt the rest to match the angle you measured, then tighten it back. Now you’re ready to start machining the taper!”}},{“@type”: “Question”,”name”: “What Are Some Common Materials Used In The Construction Of A Compound Rest, And How Do They Affect Its Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some common materials for making a compound rest are steel, aluminum, and plastic. Steel is strong and lasts a long time. Aluminum is lighter, making it easier to move, but still strong. Plastic can be less expensive and lighter, but it might not last as long as metal. Each material changes how well the compound rest works.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Alignment Issues With The Compound Rest To Ensure Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix alignment problems with the compound rest, first look at the screws and make sure they are tight. You can check the angle by using a level or a protractor, which helps you see if it’s straight. If it’s not, you can adjust it by turning the screws gently. Also, make sure the tool you’re using is set correctly. Finally, test your setup by making a small cut and checking if it’s smooth and even.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Manual Metal Lathe With A Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a manual metal lathe, always wear safety glasses to protect your eyes. Keep your hands away from moving parts and never wear loose clothing. Make sure the tool is set up correctly before starting. You should also keep your work area clean and free from clutter. Finally, never leave the machine running unattended.”}}]}