Have you ever wondered how machines shape metal into precise parts? One key player in this process is the manual metal lathe gear train. This system helps lathes spin and mold materials with great accuracy.

Imagine a clock. Each gear works together to keep time. The gear train in a lathe functions similarly. It helps the machine turn the metal smoothly, making it easier to cut and shape. Without this gear train, creating metal parts would be much harder.

Did you know that the concept of gears goes back thousands of years? Ancient inventors used simple gears to move heavy objects. Today, we still rely on this amazing technology to build our machines. The manual metal lathe gear train is a modern twist on this old idea, showing just how powerful and useful gears can be.

Understanding Manual Metal Lathe Gear Train Mechanics

Understanding the Manual Metal Lathe Gear Train

The manual metal lathe gear train is crucial for precision machining. This setup helps control the speed and movement of the cutting tool. Imagine making a perfect screw or bolt. That’s possible because of the gear train! Each gear plays a role in achieving desired rotation speeds. Users learn how to adjust gears for different tasks. Curious about how things spin? Understanding this gear train opens the door to a world of creativity in metalworking!What is a Manual Metal Lathe Gear Train?

Definition and purpose of gear trains in manual lathes. Importance of gear trains in precision machining.A gear train in a manual metal lathe is like the superhero team of the machine world. It connects different gears to control the speed and direction of the spindle. This teamwork is crucial for making pieces that fit perfectly and look fabulous. If you’ve ever tried to twist a soda bottle cap with a squeaky wheel, you’ll understand why gear trains are key—they make everything run smoothly. With precise gear ratios, they enhance accuracy in machining, ensuring your projects don’t end up as abstract art!

| Function | Importance |

|---|---|

| Speed Control | Helps achieve desired cutting speeds. |

| Direction Change | Allows flexibility in machining tasks. |

| Precision Enhancement | Ensures accurate dimensions for each piece. |

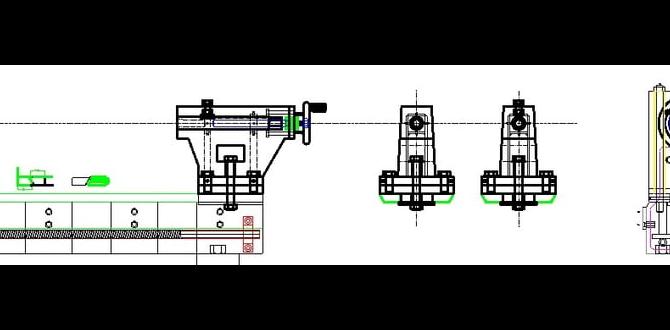

Components of a Gear Train in Manual Lathes

Detailed explanation of key components (gears, shafts, pulleys). Role of each component in the machining process.In a manual lathe, the gear train is made up of three main parts: gears, shafts, and pulleys. Each part plays a special role in making things spin properly. Gears connect together to change speed and direction. Shafts hold the gears and transfer the turning motion. Pulleys help attach belts, adding power to the system. Together, they help create smooth movements for shaping materials.

What are the key components of a manual lathe gear train?

The key components include:

- Gears: Control speed and direction.

- Shafts: Transfer motion from the motor.

- Pulleys: Connect belts to provide power.

How Gear Trains Affect Lathe Performance

Influence on speed, torque, and power transmission. Relationship between gear ratio and machining efficiency.Lathe performance improves with the right gear train. Gears help change speed and torque. This means they can make the lathe run faster or more powerfully. Gear ratio is essential, too. A higher gear ratio gives better efficiency during machining. Think of a bike. The right gears make it easier to pedal uphill. For a lathe, the same idea applies. Better gears help get the job done quicker and easier.

How do gear trains influence lathe performance?

Gear trains influence lathe performance by improving speed, torque, and power transmission. They help improve machining efficiency when the right gear ratio is chosen.

Key points:

- Faster speeds

- Increased torque

- Better power usage

- Higher efficiency through optimal gear ratios

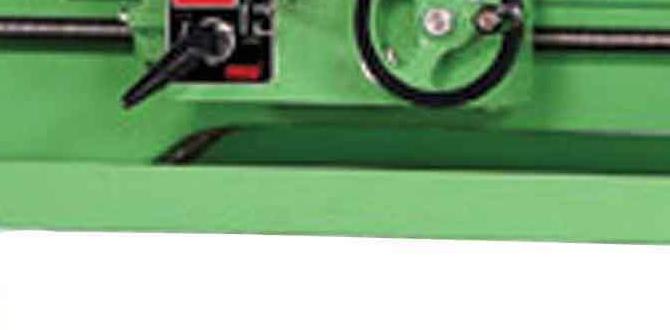

Setting Up and Adjusting Gear Trains

Stepbystep guide on setting up a gear train in a manual lathe. Tips for adjusting gear settings for optimized performance.Setting up a gear train in a manual lathe is like assembling a puzzle, but instead of a picture of a cat, you get smooth, shiny metal pieces! Start by ensuring the gears are properly fitted and aligned. Next, adjust the gear settings for optimal power. A trained hamster could run circles around your lathe if it’s set up right! Remember, less friction means faster spinning! Here’s a simple table for quick adjustments:

| Adjustment | Tip |

|---|---|

| Gear Alignment | Ensure gears mesh smoothly. |

| Lubrication | Use oil sparingly for less mess! |

| Speed Setting | Start slow, then go faster for fun! |

With these tips, your gear train will have better performance and might even win a race against your neighbor’s lawn mower!

Common Issues and Troubleshooting Gear Trains

Identification of common problems (wear, misalignment). Troubleshooting steps to resolve gear train issues.Gear trains can be tricky little beasts! Common problems include wear and misalignment. If your lathe starts acting funny, check the gears for wear. Worn gears need to retire and make way for new ones. Misalignment is like your gear train doing the cha-cha instead of its job. To fix this, make sure everything is lined up correctly. Adjustments can be a real game-changer! Here’s a simple guide:

| Issue | Troubleshooting Steps |

|---|---|

| Wear | Inspect gears, replace worn parts. |

| Misalignment | Realign gears, check settings. |

Keep your gear train happy, and it will work like a charm! Remember: a happy lathe is a productive lathe.

Maintenance Tips for Long-lasting Gear Train Performance

Recommended maintenance practices (lubrication, inspection). Importance of regular upkeep for consistent machining quality.Keeping your gear train happy is like feeding a pet—give it what it needs, and it’ll work wonders for you! Regular lubrication is key. Use the right oil to keep parts sliding smoothly, like butter on toast. Check for wear and tear often. Those little inspections can save you from big headaches later. Consistent upkeep helps ensure your machining quality stays top-notch, like pizza’s importance at a party—no one wants a soggy slice!

| Maintenance Task | Frequency |

|---|---|

| Lubrication | Every Week |

| Inspection | Monthly |

Innovations in Manual Metal Lathe Gear Train Technology

Recent advancements in gear train design and materials. Impact of technology on efficiency and precision in metalworking.Manual metal lathes are getting smarter! New gear train designs are lighter and stronger. Manufacturers use materials like carbon fiber and high-strength steel.

These changes mean more efficiency and precision in metalworking. Machines can work faster and more accurately than ever before.

- Better materials reduce wear and tear.

- Advanced designs minimize friction.

- These improvements help save time and money.

In fact, some machines now cut production time by up to 30%! Isn’t that amazing?

What are the recent advancements in manual metal lathe gear train technology?

Recent advancements include the use of lightweight materials and new designs that increase efficiency and precision.

Resources for Further Learning

Recommended books, articles, and online courses. Communities and forums for professional advice and tips.Learning about the manual metal lathe gear train can be fun! Here are some great resources. First, check out books and articles that explain the concepts simply. Online courses are nifty, too. They often have videos that will make you laugh while you learn. Joining communities and forums can boost your skills and connect you with pros. They love sharing tips and might even have secrets to share! Talk about a win-win!

| Type | Resource |

|---|---|

| Books | “Metal Lathe Basics” by J. Brown |

| Articles | “Understanding Gear Trains” from DIY Metalwork |

| Online Courses | “Lathe Mastery” on Skillshare |

| Forums | Metalworking Community on Reddit |

Conclusion

In summary, a manual metal lathe gear train helps us control the speed and torque of the lathe. Understanding its parts makes your machining work easier and more efficient. You can adjust settings for different projects. If you want to learn more, check out tutorials or guides. Experimenting with your lathe will also improve your skills and confidence.FAQs

Certainly! Here Are Five Related Questions On The Topic Of Manual Metal Lathe Gear Trains:A manual metal lathe is a tool that helps shape metal. Gear trains are used inside to change how fast the lathe spins. By changing gears, you can work with different materials. This makes it easier for you to create different shapes and sizes. Using gear trains helps you be more precise in your work!

Sure! Please provide the question you’d like me to answer.

What Is The Primary Function Of A Gear Train In A Manual Metal Lathe?The gear train in a manual metal lathe helps change the speed and direction of the cutting tool. Gears are like wheels that fit together. They can turn faster or slower depending on how they are connected. This helps you create different shapes and sizes when you work on metal. It makes the machine easier to use and more precise.

How Does The Gear Ratio In A Lathe’S Gear Train Affect The Spindle Speed And Torque Characteristics?The gear ratio in a lathe helps control how fast the spindle turns. A higher gear ratio makes the spindle spin faster, which is good for lighter tasks. A lower gear ratio gives more power or torque, helping you cut harder materials. So, by changing the gear ratio, you can choose between speed and power. This way, you can do a variety of projects easily!

What Are Some Common Types Of Gear Configurations Used In Manual Metal Lathes, And How Do They Differ In Application?On manual metal lathes, there are a few common gear setups. One is the direct drive, where power goes straight to the lathe. This is good for simple cutting. Another is a gear train, which uses different gears to change speed. This helps when we need to cut materials differently or with more precision. Choosing the right setup helps you work better on your metal projects.

How Can Wear And Tear In A Lathe’S Gear Train Impact The Overall Precision And Performance Of Machining Operations?Wear and tear in a lathe’s gear train can cause problems. Gears might not fit together well anymore. This can make the machine cut less accurately. If the cuts are not smooth, our work won’t be perfect. So, taking care of the gears helps keep our projects looking great!

What Maintenance Practices Can Be Implemented To Ensure The Longevity And Efficiency Of A Manual Metal Lathe’S Gear Train?To keep a manual metal lathe’s gear train working well, we should do a few simple things. First, clean the gears regularly to remove dust and dirt. Next, check and change the oil often to keep everything smooth. We should also look for any loose parts and tighten them. Lastly, always use the lathe gently to avoid wear and tear.