Comprehensive Manual Metal Lathe Wiring Diagram Guide

Understanding Manual Metal Lathe Wiring Diagram

A manual metal lathe wiring diagram shows how to connect the lathe’s electrical components. Knowing this can help you troubleshoot or set up your lathe correctly. Each wire plays a vital role, ensuring the machine runs safely and efficiently. Have you ever wondered how machines like lathes work? A simple understanding of the wiring can make a huge difference. With the right diagram, you can keep your lathe in tip-top shape!Understanding Manual Metal Lathes

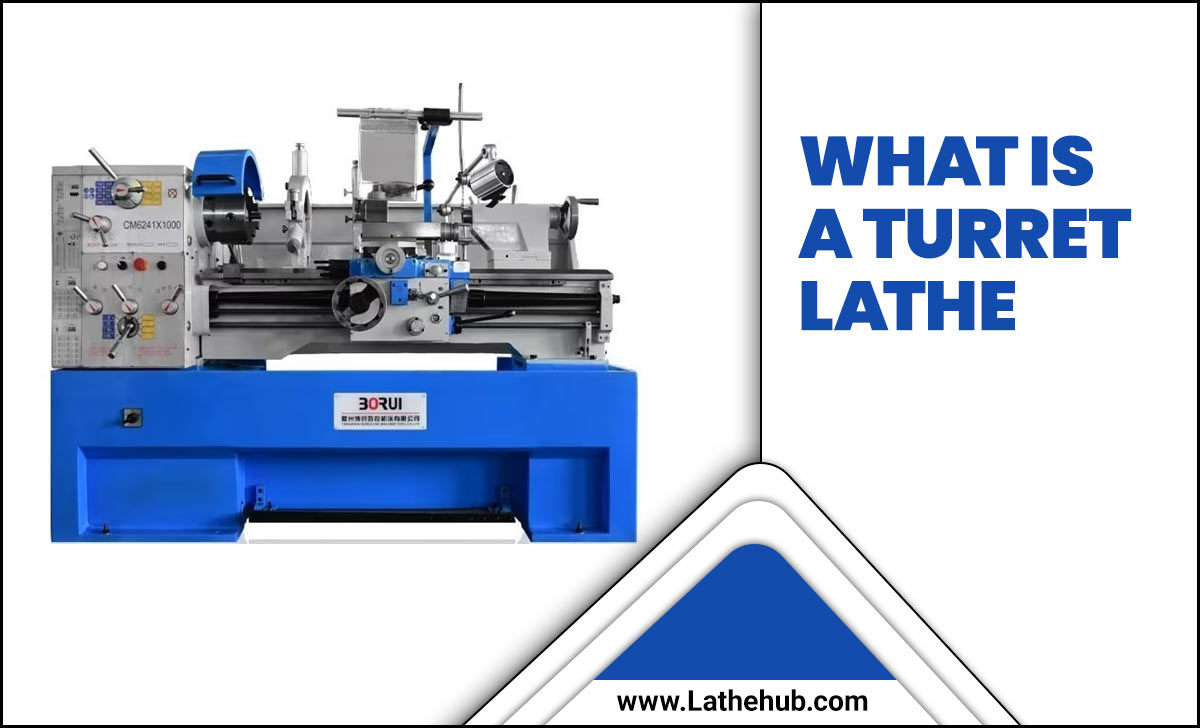

Definition and purpose of manual metal lathes. Key components and their functions.Manual metal lathes are tools that shape metal into desired forms, like magic wands for engineers! They let users cut, drill, and polish metal pieces through clever rotation and movement. The main components include the headstock, which houses the motor, and the tailstock, which supports the workpiece. Both work together, much like peanut butter and jelly, to create precise items. Here’s a quick look at their key parts:

| Component | Function |

|---|---|

| Headstock | Holds the motor and spinning chuck. |

| Tailstock | Supports and secures the metal piece. |

| Tool post | Holds cutting tools in place. |

| Bed | Base that supports the whole lathe. |

Learning about these parts makes working with manual metal lathes feel like being a wizard in a workshop!

Importance of Wiring Diagrams

Role of wiring diagrams in machine operation. Benefits of having a clear wiring guide.Wiring diagrams are very important for machines like metal lathes. They show how everything connects and works together. A clear wiring guide helps workers find problems quickly. This saves time and money. A good diagram can also prevent accidents. Here are some benefits:

- Clearly shows connections.

- Speeds up repairs.

- Reduces mistakes.

- Helps in maintenance.

In short, wiring diagrams make it easier to operate machines safely and efficiently.

Why are wiring diagrams crucial for machines?

Wiring diagrams are crucial because they help everyone understand how a machine works. They make troubleshooting simpler, ensure safety, and improve maintenance.

Steps to Create a Manual Metal Lathe Wiring Diagram

Tools and materials required for diagram creation. Detailed stepbystep guide for wiring layout.To create a wiring diagram for a manual metal lathe, gather the right tools and materials. You’ll need pen and paper, a ruler, and a multimeter. Start with a clear plan of your lathe components. Then, follow these simple steps:

- Draw the main parts like the motor and switches.

- Use lines to show how wires connect each part.

- Label each connection to avoid confusion.

- Check your diagram with a multimeter to ensure accuracy.

This process helps even beginners understand how things are wired together!

What tools do you need for a wiring diagram?

You’ll need paper, pen, ruler, and multimeter for your wiring diagram.

Interpreting Existing Wiring Diagrams

How to read and understand wiring symbols. Tips for troubleshooting based on diagrams.Reading wiring diagrams can seem tricky, but it doesn’t have to be! First, identify wiring symbols; they represent different components. Each symbol has a meaning, like a secret code. Here are some tips:

- Look for the legend or key; it explains the symbols.

- Follow the paths; they show how electricity moves.

- Compare with your machine; see if it matches.

If something doesn’t work, use the diagram to trace issues. Follow the lines and check each part. Keep calm, and you’ll figure it out!

What are the common wiring symbols?

Common wiring symbols include circles for lights, squares for switches, and lines for wires. Each symbol has a specific meaning that guides you when reading diagrams.

How do I troubleshoot using the diagram?

- Check connections carefully.

- Look for broken wires.

- Use a multimeter to measure voltage.

Safety Precautions When Wiring a Metal Lathe

Common hazards associated with wiring. Best practices for ensuring safety during installation.Wiring a metal lathe can be risky. Hazards like electric shocks and short circuits can surprise you like a hidden cat! Always wear protective gear, such as gloves and safety goggles. Keep your workspace dry and tidy; it’s hard to trip over a cord if it’s not lying around. Turn off the power before touching any wires. And remember, plan your wiring layout ahead to avoid any messy tangles!

| Hazard | Safety Tip |

|---|---|

| Electric Shock | Always switch off the power! |

| Short Circuits | Check connections twice! |

| Clutter | Keep wires organized! |

Follow these tips, and you’ll be the wiring wizard of the workshop!

Examples of Manual Metal Lathe Wiring Diagrams

Showcase of different wiring diagrams for various lathe models. Analysis of notable differences and adaptations.Manual metal lathe wiring diagrams come in various shapes and sizes. Each model has a unique twist. For instance, one diagram might connect wires in a way that looks like a spaghetti dinner gone wild! Meanwhile, another model may keep things neat and tidy, resembling a well-organized tool shed. Differences in designs help users adapt their machines for specific tasks. They keep our lathes running smoothly, even if the diagrams are as puzzling as a Rubik’s cube!

| Lathe Model | Wiring Features |

|---|---|

| Model A | Basic connection setup, fewer wires |

| Model B | Complex wiring with multiple switches |

| Model C | Upgraded features for advanced operations |

Understanding these diagrams is like learning a new dance. At first, it feels awkward, but with practice, you’ll be a pro in no time!

Troubleshooting Common Wiring Issues

Identification of common wiring problems and their causes. Solutions and preventative measures.Wiring problems can be sneaky little gremlins in your manual metal lathe. Common issues include frayed wires and loose connections. Frayed wires can cause shorts, while loose connections make machines grumpy. To solve these, check all wires carefully and tighten any loose screws. Don’t forget to look for signs of wear. Regular checks can save you from big headaches! Here’s a quick table of common issues, causes, and fixes:

| Problem | Cause | Solution |

|---|---|---|

| Frayed Wires | Wear and tear | Replace or tape |

| Loose Connections | Vibration | Tighten screws |

| Motor Not Running | Power issues | Check power source |

Follow these simple steps to keep your lathe happy and humming like a kitten at nap time!

Resources for Further Learning

Recommended books and websites on manual lathes. Communities and forums for lathe enthusiasts.Learning about manual lathes can be exciting! Here are some great resources to explore:

- Books: “Manual Lathe Basics” and “The Art of Turning”. These books cover everything you need to know.

- Websites: Check out LatheTools.com and MachinistForums.com for helpful tips and tricks.

- Communities: Join groups on Facebook or forums like Reddit to share ideas and get help from other lathe lovers.

Conclusion

In summary, a manual metal lathe wiring diagram is essential for understanding your machine’s electrical setup. By following the diagram, you can ensure safe and proper connections. Remember to take your time and double-check your work. If you’re curious, explore more resources or tutorials to deepen your knowledge. Happy machining!FAQs

What Are The Essential Components Included In A Manual Metal Lathe Wiring Diagram?A manual metal lathe wiring diagram shows how to connect the wires. It includes a power source, which provides electricity. You’ll also see the motor, which makes the lathe turn. There are switches to start and stop the machine too. Lastly, it shows the connections for safety features to keep everyone safe.

How Can I Identify The Power Supply Connections In A Manual Metal Lathe Wiring Diagram?To find power supply connections in a manual metal lathe wiring diagram, look for the lines labeled “Power” or “Voltage.” These lines usually come from a plug or outlet. We can recognize them because they often connect to the motor. You might see symbols like circles or dots at the ends of the wires—these are important spots to check. Follow these lines to see where they go, and you’ll find your power supply connections!

What Safety Measures Should Be Considered When Interpreting A Manual Metal Lathe Wiring Diagram?When looking at a manual metal lathe wiring diagram, you should always be careful. First, make sure the machine is unplugged before you start. This keeps you safe from electric shocks. Next, wear safety glasses to protect your eyes. Lastly, ask an adult for help if you don’t understand something.

How Do The Wiring Configurations Differ Between Single-Phase And Three-Phase Manual Metal Lathes?Single-phase lathes use two wires for electricity. You find one wire carrying the current and one wire for returning it. In contrast, three-phase lathes use three wires. These wires share the power load, making them stronger and more efficient. This means three-phase lathes can run bigger machines better than single-phase ones.

Where Can I Find A Reliable Manual Metal Lathe Wiring Diagram For Specific Lathe Models?You can find a reliable wiring diagram for your specific metal lathe by checking the owner’s manual. If you don’t have the manual, look online on the manufacturer’s website. You can also visit forums where other lathe users share their diagrams. Libraries or tool shops may have useful books too.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Included In A Manual Metal Lathe Wiring Diagram? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A manual metal lathe wiring diagram shows how to connect the wires. It includes a power source, which provides electricity. You’ll also see the motor, which makes the lathe turn. There are switches to start and stop the machine too. Lastly, it shows the connections for safety features to keep everyone safe.”}},{“@type”: “Question”,”name”: “How Can I Identify The Power Supply Connections In A Manual Metal Lathe Wiring Diagram? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find power supply connections in a manual metal lathe wiring diagram, look for the lines labeled Power or Voltage. These lines usually come from a plug or outlet. We can recognize them because they often connect to the motor. You might see symbols like circles or dots at the ends of the wires—these are important spots to check. Follow these lines to see where they go, and you’ll find your power supply connections!”}},{“@type”: “Question”,”name”: “What Safety Measures Should Be Considered When Interpreting A Manual Metal Lathe Wiring Diagram? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When looking at a manual metal lathe wiring diagram, you should always be careful. First, make sure the machine is unplugged before you start. This keeps you safe from electric shocks. Next, wear safety glasses to protect your eyes. Lastly, ask an adult for help if you don’t understand something.”}},{“@type”: “Question”,”name”: “How Do The Wiring Configurations Differ Between Single-Phase And Three-Phase Manual Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Single-phase lathes use two wires for electricity. You find one wire carrying the current and one wire for returning it. In contrast, three-phase lathes use three wires. These wires share the power load, making them stronger and more efficient. This means three-phase lathes can run bigger machines better than single-phase ones.”}},{“@type”: “Question”,”name”: “Where Can I Find A Reliable Manual Metal Lathe Wiring Diagram For Specific Lathe Models? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find a reliable wiring diagram for your specific metal lathe by checking the owner’s manual. If you don’t have the manual, look online on the manufacturer’s website. You can also visit forums where other lathe users share their diagrams. Libraries or tool shops may have useful books too.”}}]}