Have you ever seen a metal lathe in action? It’s like magic how it shapes metal into parts. But sometimes, the cross slide can act up. This can make your work slow and frustrating. You might wonder, “Why isn’t my metal lathe cross slide moving smoothly?”

Don’t worry! You’re not alone in facing these problems. Many people who use lathes face similar issues. A simple hiccup with the cross slide can stall your project. Did you know that even small fixes can make a big difference?

Join us as we explore how to troubleshoot your metal lathe cross slide. With the right steps, you can fix common problems easily. Get ready to learn and get your lathe running perfectly again!

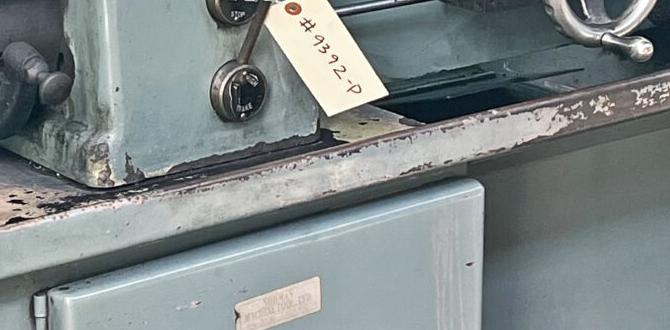

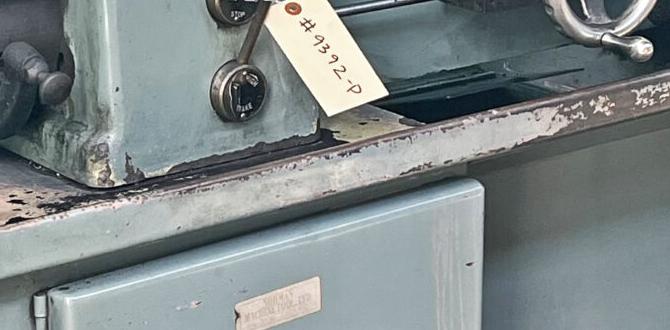

Metal Lathe Cross Slide Troubleshooting Tips And Techniques

Metal Lathe Cross Slide Troubleshooting

Having trouble with your metal lathe’s cross slide? You’re not alone! Many users face similar issues. Common problems include uneven movement or sticking. These can be fixed by checking the lubrication and cleaning the slide. Sometimes, loose bolts cause misalignment. A quick inspection often prevents bigger breakdowns. Did you know that regular maintenance can extend your lathe’s life? Understanding these simple tips makes the process easier and more efficient for everyone.Common Issues with Cross Slides

Description of typical problems encountered with cross slides. Impact of these issues on machining accuracy and efficiency.Cross slides can be a bit tricky, like trying to herd cats! Common problems include slippage, uneven movement, and even sticking. These issues can ruin your machining accuracy and slow you down, making it feel like you’re moving in slow motion. If your cross slide is not correctly aligned, it can affect your cuts, leading to a messy finish. Here’s a quick table of some typical issues:

| Issue | Effect |

|---|---|

| Slippage | Inaccurate cuts and wasted time |

| Sticking | Slow down the machining process |

| Uneven movement | Poor finish on workpieces |

Fixing these problems is key to smooth sailing in your machining adventures. Remember, a well-functioning cross slide is happier and helps you make better parts!

Diagnosing Cross Slide Problems

Stepbystep guide on how to identify cross slide issues. Tools and techniques for effective troubleshooting.Finding issues with your metal lathe’s cross slide can seem hard, but it’s easy! Start by checking for any loose parts or damage. Look at the adjustment mechanism carefully. Make sure everything moves smoothly. Use a straight edge to check for alignment. If there’s a problem with movement, clean and lubricate all moving parts. You may also need a few tools like:

- Feeler gauge for checking gaps

- Calipers for measuring

- Clean cloths for wiping dust

Follow these steps and you’ll be on your way to fixing your lathe!

How can I identify cross slide issues?

Inspect for loose components and ensure all screws are tight. Test movement to feel for smooth operation. You can also check for any signs of wear or corrosion.

Tightening and Adjustment Techniques

Guidelines for proper tightening of the cross slide. Stepbystep adjustments to improve performance.Getting the cross slide to work perfectly is like tuning a guitar. First, check the screws. If they’re too loose, your slide might wobble like a jelly on a rollercoaster. Tighten them gently—think “snug,” not “Hulk smash.” Next, you can adjust the gibs. Loosening the gibs can help your slide move smoothly. Remember to also clean the ways; a little oil can be like giving your lathe a spa day!

| Step | Action |

|---|---|

| 1 | Check and tighten screws |

| 2 | Adjust the gibs |

| 3 | Clean and oil the ways |

Follow these tips, and your cross slide will sing like a bird. A well-adjusted lathe not only performs better but also lasts longer. So, get your tools ready and keep your lathe happy!

Maintenance Practices for Longevity

Recommended maintenance routines to prevent cross slide issues. Importance of lubrication and cleaning in maintaining the cross slide.Keeping your cross slide in tip-top shape is like giving a pig a spa day—everyone wins! Regular maintenance is key to avoiding those pesky issues. Use a soft cloth to keep grime at bay. Lubrication is your best friend here! A little oil goes a long way in preventing wear and tear. Plus, it ensures smooth operation, like butter on toast. Bringing in a cleaning routine can prolong your machine’s life. Here’s a quick table for some handy tips:

| Practice | Frequency | Notes |

|---|---|---|

| Clean surface | Daily | Remove dust and debris. |

| Lubricate | Weekly | Use the right oil. |

| Inspect for wear | Monthly | Check for any damage. |

Take care of your equipment, and it will take care of you!

Troubleshooting Techniques for Specific Symptoms

Addressing issues like backlash, binding, and movement irregularities. Solutions for each symptom with detailed steps.Sometimes, your metal lathe can feel like it’s playing hide and seek! If you notice backlash, it means parts have too much play. You can fix this by tightening the gib screws. If your slide feels like it’s stuck in glue, that’s binding. Try cleaning the ways and applying a bit of oil. For movement irregularities, check for any loose screws or misaligned parts. Remember, a little adjustment can transform your machine into a smooth operator!

| Symptom | Solution |

|---|---|

| Backlash | Tighten the gib screws |

| Binding | Clean the ways and add oil |

| Irregular Movement | Check screws and alignment |

When to Seek Professional Help

Signs that indicate a need for expert intervention. Benefits of consulting with a professional machinist or technician.Sometimes, a metal lathe can cause problems that seem too big to handle. Here are some signs that it’s time to call a professional:

- Unusual noises while operating

- Difficulty in adjusting the cross slide

- Visible damage or wear on parts

- Frequent tool breakage

Getting help from a machinist or technician brings many benefits. They can:

- Diagnose issues quickly

- Provide expert repairs

- Ensure your lathe runs safely

- Extend the machine’s lifespan

Don’t hesitate to seek help. A skilled expert can prevent bigger problems down the line.

When to Call a Professional?

If you see any of these signs, it’s best to contact a professional. They can fix issues effectively and keep your machine running smoothly.

Preventative Measures to Avoid Future Problems

Strategies to enhance the reliability of the cross slide system. Best practices for regular checks and adjustments.To keep your cross slide system in tip-top shape, regular checks are a must! Just like you wouldn’t ignore a pet’s need for food, don’t ignore your lathe. Check the slide adjustment often, so it doesn’t become a stubborn mule. Cleaning the system is also key—grit and grime are like sandpaper for your parts! Here’s a quick checklist:

| Task | Frequency |

|---|---|

| Clean the cross slide | Weekly |

| Check for loose screws | Monthly |

| Inspect lubrication levels | Every 3 months |

Following these tips can help your lathe run smoothly. Remember, a happy lathe means less hassle for you!

Conclusion

In conclusion, troubleshooting a metal lathe cross slide requires careful checks of all components. Start with the leadscrew and handle for any jams. Next, inspect the slide for wear or damage. Regular maintenance keeps your lathe running smoothly. We encourage you to explore more guides or seek help from experts. Happy machining!FAQs

What Are Common Signs That Indicate A Problem With The Cross Slide On A Metal Lathe?If you notice your metal lathe isn’t cutting evenly, that could be a sign. You might see uneven lines on the metal. The cross slide may also feel sticky or hard to move. If it makes strange noises while moving, there could be a problem too. These signs mean it’s time to check the cross slide more closely.

How Can Misalignment Of The Cross Slide Affect The Precision Of Machining Operations?If the cross slide is not lined up right, it can cause problems when we cut or shape materials. It might make parts too big or too small. This means our finished pieces won’t fit together well. We need to ensure everything is aligned to make accurate and good-quality work.

What Steps Can Be Taken To Adjust And Calibrate A Metal Lathe’S Cross Slide For Optimal Performance?To adjust and calibrate a metal lathe’s cross slide, first, check if it moves smoothly. You can do this by turning the handwheel. If it feels tight, loosen the adjusting screws a little. Next, make sure the cross slide is level. Use a small level tool to check this. Finally, test it by cutting a small piece of metal and see if it works well.

What Are The Best Practices For Maintaining The Cross Slide And Preventing Damage Or Wear Over Time?To keep the cross slide in good shape, we should clean it regularly. Use a soft cloth to wipe away dust and dirt. Lubricate moving parts with oil to help them slide smoothly. Always check for any loose screws and tighten them if needed. Finally, try not to force anything, as that can cause damage.

How Can One Diagnose And Fix Issues Such As Excessive Backlash In The Cross Slide Mechanism?To find excessive backlash in the cross slide, you can use a dial indicator. First, attach the dial indicator to the slide. Then, move the slide back and forth. If the dial moves too much without touching the work, you have backlash. To fix it, look for adjustment screws on the mechanism. Tighten them a little to reduce the gap. Test again to see if the backlash is better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are Common Signs That Indicate A Problem With The Cross Slide On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you notice your metal lathe isn’t cutting evenly, that could be a sign. You might see uneven lines on the metal. The cross slide may also feel sticky or hard to move. If it makes strange noises while moving, there could be a problem too. These signs mean it’s time to check the cross slide more closely.”}},{“@type”: “Question”,”name”: “How Can Misalignment Of The Cross Slide Affect The Precision Of Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the cross slide is not lined up right, it can cause problems when we cut or shape materials. It might make parts too big or too small. This means our finished pieces won’t fit together well. We need to ensure everything is aligned to make accurate and good-quality work.”}},{“@type”: “Question”,”name”: “What Steps Can Be Taken To Adjust And Calibrate A Metal Lathe’S Cross Slide For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust and calibrate a metal lathe’s cross slide, first, check if it moves smoothly. You can do this by turning the handwheel. If it feels tight, loosen the adjusting screws a little. Next, make sure the cross slide is level. Use a small level tool to check this. Finally, test it by cutting a small piece of metal and see if it works well.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining The Cross Slide And Preventing Damage Or Wear Over Time? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the cross slide in good shape, we should clean it regularly. Use a soft cloth to wipe away dust and dirt. Lubricate moving parts with oil to help them slide smoothly. Always check for any loose screws and tighten them if needed. Finally, try not to force anything, as that can cause damage.”}},{“@type”: “Question”,”name”: “How Can One Diagnose And Fix Issues Such As Excessive Backlash In The Cross Slide Mechanism? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find excessive backlash in the cross slide, you can use a dial indicator. First, attach the dial indicator to the slide. Then, move the slide back and forth. If the dial moves too much without touching the work, you have backlash. To fix it, look for adjustment screws on the mechanism. Tighten them a little to reduce the gap. Test again to see if the backlash is better.”}}]}