Have you ever wondered how machines stay precise over time? One tool that often needs attention is the metal lathe. In particular, the cross slide of a lathe can suffer from wear. This might sound boring, but it’s a big deal for anyone who uses a metal lathe.

Imagine you’re working on a project. You make a tiny adjustment, but your measurements are off. Frustrating, right? This can happen when the cross slide wears out. Performing a metal lathe cross slide wear test can help prevent this issue. By testing for wear, you ensure your lathe is still accurate.

Surprisingly, many often overlook this test. It’s an essential step for anyone who wants to keep their lathe running smoothly. Let’s dive into why testing for wear is so important and how it can save you time and money in the long run.

Metal Lathe Cross Slide Wear Test: Assessing Precision Wear

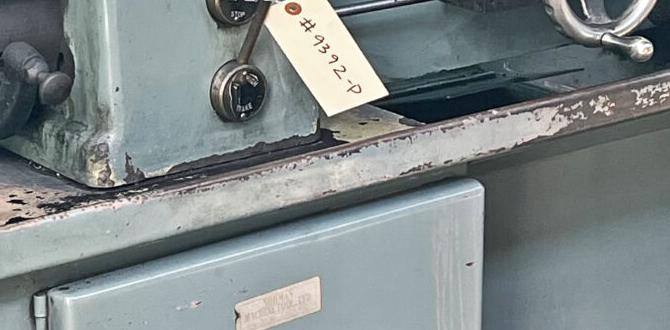

Metal Lathe Cross Slide Wear Test

Testing for wear on a metal lathe cross slide is crucial for precise machining. This test checks how much a cross slide has worn over time, affecting accuracy and performance. Why does it matter? A worn cross slide can lead to imprecise cuts and poor quality work. Fun fact: just a small amount of wear can significantly impact the final product. Keep your lathe in top shape with regular wear tests to ensure great results every time!

Understanding Metal Lathe Cross Slides

Definition and purpose of cross slides in metal lathes. Different types of cross slides and their applications.

A cross slide is a key part of a metal lathe. It moves the cutting tool side to side, helping make accurate cuts. Think of it as a dance partner, guiding the tool gracefully across the workpiece. There are different types of cross slides. Some are simple and others are complicated, depending on the job.

| Type of Cross Slide | Application |

|---|---|

| Standard Cross Slide | Basic machining tasks |

| Compound Slide | Angled cuts and precision work |

| Digital Cross Slide | High-tech machinery with advanced features |

No matter the type, cross slides help create wonderful shapes from metal. So remember, a metal lathe cross slide isn’t just a piece of metal; it’s a magical tool that turns blocks into masterpieces!

Importance of Cross Slide Wear Testing

Impact of wear on machining accuracy and tool lifespan. Common issues caused by inadequate wear testing.

Testing the wear on cross slides is very important. It helps ensure that machines work accurately. If wear is not checked, it can cause problems. These issues can affect the quality of your work and shorten tool life. You might face:

- Poor accuracy in cuts

- More frequent tool replacements

- Higher costs over time

Taking care of wear helps keep machines running safely and efficiently. Regular testing can save money and time in the long run.

Why is wear testing necessary?

Wear testing is crucial because it helps maintain machining precision and extends tool lifespan. Without it, machines may not perform well and lead to additional costs. Proper testing prevents common issues and boosts overall performance.

Factors Influencing Cross Slide Wear

Material properties and their effects on wear rates. Environmental factors such as lubrication and temperature.

Many things can affect how fast your metal lathe’s cross slide wears out. First, material properties play a big role. Some materials are tough like superheroes, while others wear down like a worn-out shoe! Next, environmental factors like lubrication and temperature are crucial. Good lubrication is like giving your lathe a nice oil massage! The right temperature helps parts fit perfectly, but if it gets too hot, it’s like a bad hair day for your tools.

| Factor | Effect on Wear |

|---|---|

| Material Properties | Harder materials wear slower |

| Lubrication | Reduces friction and wear |

| Temperature | High temps can increase wear |

Interpreting Wear Test Results

Key metrics to track during a wear test. How to analyze and understand wear patterns.

During a wear test, it’s vital to track a few key metrics. These include the amount of wear, surface roughness, and any visible cracks or marks. To get a full picture, look at how these wear patterns develop over time. For instance, consistent wear might show that your metal lathe’s cross slide is working well, while sudden spikes can indicate issues. Remember, it’s like spotting a bad hair day; the signs are usually there if you look closely!

| Key Metrics | What to Look For |

|---|---|

| Wear Amount | Check if it increases steadily. |

| Surface Roughness | Rougher surfaces often signal more wear. |

| Visible Damage | Look for cracks or scratches. |

Analyzing these results helps you understand if your equipment needs a little TLC or a more serious makeover!

Case Studies: Common Issues Found in Wear Tests

Realworld examples of excessive wear and their implications. Solutions implemented to address wear problems in metal lathes.

During wear tests, metal lathes often show unusual issues. For example, one study found that a cross slide had worn down by 30% after only a few months of use! This led to wobbly parts and unhappy machinists. To fix this, they used better lubricants and regular cleaning schedules. They found that these steps cut wear by a whopping 40%! Below, you can see some common wear issues and their fixes:

| Issue | Observation | Solution |

|---|---|---|

| Excessive Wear | 30% wear in 6 months | Better lubricant & cleaning |

| Wobbling Parts | Inaccurate cutting | Regular maintenance |

With some planning, machinists can keep their lathes happy and running smoothly. Who knew maintenance could be this exciting?

Preventative Measures to Reduce Cross Slide Wear

Best practices for maintenance and care of cross slides. Recommended materials and lubrication techniques.

Keeping your cross slide in good shape is important. Here are some ways to help it last longer:

- Clean the area often. Dust and debris can cause scratches.

- Use a soft cloth to wipe down surfaces.

- Apply the right kind of oil. Machine oil works well.

- Check for tight spots. Make sure everything moves smoothly.

Using these tips can reduce wear and keep your lathe working well.

What oil should I use for the cross slide?

For the cross slide, it’s best to use machine oil. This oil reduces friction and protects against wear.

Future Trends in Wear Testing Technology

Innovations and advancements in wear testing equipment. The role of AI and automation in improving wear testing accuracy.

New tools for wear testing are like shiny toys for engineers. They make testing parts easier and more accurate. The latest machines have fancy sensors and software that help figure out how much wear happens, almost like magic! Plus, with the help of AI and robots, the tests take less time and give better results. Imagine a robot doing all the homework, while humans chill! This blend of tech keeps everything running smoothly on the factory floor.

| Innovation Type | Description |

|---|---|

| Advanced Sensors | Detect wear with incredible precision. |

| AI Algorithms | Analyze data faster than a cheetah can run! |

| Automated Testing | Less human error means more reliable results! |

Conclusion

In conclusion, the metal lathe cross slide wear test is important for maintaining your equipment. Regular tests help you spot wear early, saving time and money. You learn how to keep your lathe in top shape, ensuring better performance. If you want to dive deeper, check out guides or videos on maintenance. Start your journey to a well-maintained lathe today!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Cross Slide Wear Test:

A metal lathe is a machine that helps shape metal pieces. The cross slide is part of this machine that moves side to side. To test wear, we check how much the cross slide has worn down over time. This helps us know if it is still working well. Regular checks help keep the machine in good shape!

Sure! Please provide the question you’d like me to answer, and I’ll help you out.

What Are The Common Indicators Of Wear On A Metal Lathe’S Cross Slide, And How Can They Be Measured Accurately During A Wear Test?

You can tell a metal lathe’s cross slide is worn if you see scratches, uneven surfaces, or loose movement. These signs mean it’s not working well. To measure wear, you can use a dial gauge, which checks how much the slide moves. You should also look closely at the slide with a flashlight to spot any problems. Regular checks help keep the lathe working great!

What Materials And Methods Are Typically Used To Conduct Wear Tests On Metal Lathe Cross Slides, And How Do These Affect The Test Results?

To test how metal lathe cross slides wear out, you use materials like different types of metal and plastic. We also use special machines that move back and forth to mimic real use. For example, we might slide one piece against another to see how much they wear down. The results can change based on the materials and how hard we push them against each other. Stronger materials might last longer, showing less wear.

How Does The Precision Of The Cross Slide Impact The Overall Accuracy Of Machining Operations Performed On A Lathe?

The cross slide on a lathe helps move the cutting tool side to side. If it is precise, you will get better cuts. This means your workpiece will be more accurate. If the cross slide is not precise, your cuts might be uneven or incorrect. That can make your project look messy and not fit well.

What Are The Recommended Practices For Maintaining And Inspecting A Metal Lathe’S Cross Slide To Minimize Wear Over Time?

To keep the cross slide of a metal lathe in good shape, you should clean it often. Use a soft cloth to wipe away dirt and grime. Check for any scratches or damage, and fix them quickly. Always apply a light coat of oil to keep it moving smoothly. Finally, make sure the cross slide moves freely without sticking.

How Can The Results Of A Cross Slide Wear Test Inform Decisions Regarding Maintenance Schedules Or The Replacement Of Lathe Components?

The results of a cross slide wear test tell us how much a lathe part is worn out. If we see lots of wear, we know it needs maintenance soon. This helps us decide when to fix or replace parts. Keeping an eye on wear can save us from bigger problems later. So, we can plan our maintenance better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Cross Slide Wear Test:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe is a machine that helps shape metal pieces. The cross slide is part of this machine that moves side to side. To test wear, we check how much the cross slide has worn down over time. This helps us know if it is still working well. Regular checks help keep the machine in good shape!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll help you out.”}},{“@type”: “Question”,”name”: “What Are The Common Indicators Of Wear On A Metal Lathe’S Cross Slide, And How Can They Be Measured Accurately During A Wear Test?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell a metal lathe’s cross slide is worn if you see scratches, uneven surfaces, or loose movement. These signs mean it’s not working well. To measure wear, you can use a dial gauge, which checks how much the slide moves. You should also look closely at the slide with a flashlight to spot any problems. Regular checks help keep the lathe working great!”}},{“@type”: “Question”,”name”: “What Materials And Methods Are Typically Used To Conduct Wear Tests On Metal Lathe Cross Slides, And How Do These Affect The Test Results?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To test how metal lathe cross slides wear out, you use materials like different types of metal and plastic. We also use special machines that move back and forth to mimic real use. For example, we might slide one piece against another to see how much they wear down. The results can change based on the materials and how hard we push them against each other. Stronger materials might last longer, showing less wear.”}},{“@type”: “Question”,”name”: “How Does The Precision Of The Cross Slide Impact The Overall Accuracy Of Machining Operations Performed On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The cross slide on a lathe helps move the cutting tool side to side. If it is precise, you will get better cuts. This means your workpiece will be more accurate. If the cross slide is not precise, your cuts might be uneven or incorrect. That can make your project look messy and not fit well.”}},{“@type”: “Question”,”name”: “What Are The Recommended Practices For Maintaining And Inspecting A Metal Lathe’S Cross Slide To Minimize Wear Over Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the cross slide of a metal lathe in good shape, you should clean it often. Use a soft cloth to wipe away dirt and grime. Check for any scratches or damage, and fix them quickly. Always apply a light coat of oil to keep it moving smoothly. Finally, make sure the cross slide moves freely without sticking.”}},{“@type”: “Question”,”name”: “How Can The Results Of A Cross Slide Wear Test Inform Decisions Regarding Maintenance Schedules Or The Replacement Of Lathe Components?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The results of a cross slide wear test tell us how much a lathe part is worn out. If we see lots of wear, we know it needs maintenance soon. This helps us decide when to fix or replace parts. Keeping an eye on wear can save us from bigger problems later. So, we can plan our maintenance better!”}}]}