Have you ever seen a metal lathe in action? It’s fascinating! This machine turns raw metal into beautiful and precise shapes. But there’s something that can make a big difference in the work you do: knurling depth control.

Knurling is a process where we add a textured pattern to the surface of the metal. This pattern improves grip and looks great too! But how do we control the depth of that knurling? That’s where the magic happens.

Imagine you are holding a tool that just doesn’t fit right. Frustrating, isn’t it? That’s why getting the knurling depth right is so important. If it’s too deep, you might ruin your piece. If it’s too shallow, it won’t grip well. Finding that perfect balance can be tricky.

In this article, we will explore the secrets of metal lathe knurling depth control. You’ll learn tips and tricks that can help you master your craft. Ready to dive in and discover more?

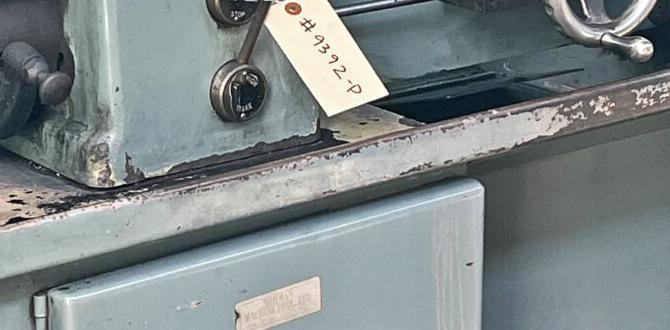

Metal Lathe Knurling Depth Control: A Comprehensive Guide

Metal Lathe Knurling Depth Control

Controlling knurling depth on a metal lathe is crucial for precise work. It ensures that knobs or handles fit just right. Did you know that too deep of a knurl can weaken your piece? Using the right settings helps create a strong, textured surface. Adjustments depend on material and tool type. Beginners may find it tricky, but with practice, you will master this skill. Perfecting knurling can enhance your projects and impress others with your craftsmanship!Understanding Knurling and Its Importance

Definition and purpose of knurling in metalworking. Types of knurl patterns and their applications.Knurling is a metalworking process that creates a textured pattern on metal surfaces. This texture helps improve grip and can make items look more attractive. Think of it as giving your metal a little fashion makeover! There are various knurl patterns, such as straight, diamond, and circular, each serving different uses. For example, a straight knurl is best for items needing a solid grip, while a diamond pattern adds style and function.

| Knurl Pattern | Application |

|---|---|

| Straight | Tools and handles |

| Diamond | Decorative items |

| Circular | Fittings |

Setting Up Your Metal Lathe for Knurling

Stepbystep guide on preparing a metal lathe for knurling. Importance of proper tool selection and alignment.Getting your metal lathe ready for knurling is like prepping for a fun cooking show! First, choose the right knurling tool. It’s crucial for making those cool patterns. Next, align the tool correctly; a wobbly tool is like a chef with a dull knife—no fun!

| Step | Action |

|---|---|

| 1 | Select the right knurling tool |

| 2 | Align the tool properly |

| 3 | Adjust the depth control for perfect patterns |

Without proper alignment, your knurling might end up looking like a pizza with toppings all over! Remember, practice makes perfect, so don’t worry if it’s not perfect on your first try. Keep going, and soon you’ll be a knurling pro!

Methods for Controlling Knurling Depth

Adjustable tool holder techniques and advantages. Manual vs. automated depth control methods.Controlling how deep you knurl can feel like trying to tame a wild beast. Luckily, you have options! First up, adjustable tool holders are your trusty sidekicks. They let you change the depth easily, so you can go from light patterns to deep grooves with a twist. It’s like adjusting your hat size—easy peasy!

Next, let’s chat about manual versus automated methods. Manual controls are great when you enjoy a hands-on approach. But if you want precision without the fuss, try automated options. They can help you get the job done faster—like having your own robot helper saying, “I got this!”

| Method | Advantages |

|---|---|

| Adjustable Tool Holder | Easily changeable, gives flexibility |

| Manual Control | Hands-on experience, allows for personal touch |

| Automated Control | Precision and efficiency |

So whether you’re spinning knobs or pressing buttons, you’ll find the best method for knurling depth that suits you!

Factors Affecting Knurling Depth Consistency

Material properties and their influence on knurling results. Impact of lathe speed and feed rate on depth accuracy.Knurling depth is influenced by various factors. First, the material properties matter. Softer metals may lead to deeper knurls, while harder metals can result in shallower ones. Lathe speed also plays a role. Higher speeds can create finer patterns, but too fast might damage the workpiece. Feed rate affects how quickly the tool moves. A slower feed rate often gives better depth control. Balancing these factors is key for consistent results.

What factors impact knurling depth?

Material hardness, lathe speed, and feed rate all significantly affect knurling depth. Softer materials allow deeper grooves, while the right lathe settings ensure accuracy.

Troubleshooting Common Knurling Depth Issues

Identifying and resolving under or over knurling problems. Tips for achieving consistent depth across multiple pieces.Sometimes, knurling can go wrong. You might notice under-knurling, which means the texture isn’t deep enough. Or you might face over-knurling, where it gets too deep. To fix this, check your tool height and speed. Adjusting these can help. For even depth across pieces, try these tips:

- Use the same pressure for each piece.

- Keep the metal and tool clean.

- Measure depth settings carefully.

Following these steps can help you make perfect knurls every time.

How can I fix uneven knurling depth?

To fix uneven knurling depth, ensure your tool and workpiece are stable and clean. Check your feed rate and pressure during operation. A smooth, consistent motion is key.

Best Practices for Successful Metal Lathe Knurling

Recommended settings for various materials and knurl types. Maintenance tips for ensuring lathe and tool longevity.To achieve great results with knurling on a metal lathe, we need the right settings for different materials. For softer metals like aluminum, a shallower depth works best, while tougher materials like steel require deeper cuts. Check your knurl type too; cross-hatch patterns are a crowd favorite! Don’t forget maintenance—clean your tool and lathe regularly. A happy lathe is a productive lathe. Remember, “A clean lathe is a happy lathe!”

| Material | Recommended Knurl Depth | Knurl Type |

|---|---|---|

| Aluminum | 0.005 – 0.015 inches | Straight |

| Brass | 0.010 – 0.020 inches | Diamond |

| Steel | 0.020 – 0.030 inches | Cross-hatch |

Staying on top of maintenance can extend the life of your lathe by up to 50%. That’s like having two metal lathes for the price of one! So, put on your best apron and keep that lathe running smoothly.

Advanced Techniques in Metal Lathe Knurling

Exploring CNC lathe options for precision knurling. Innovative methods for customized knurl patterns.Using CNC lathes for knurling is an exciting way to create precise patterns. These machines offer high accuracy, which helps achieve consistent results. You can also explore special tools for creating unique knurl designs. These innovative methods allow for creativity, making projects more personalized. The combination of technology and skill leads to amazing outcomes.

What are some CNC lathe options for precision knurling?

CNC lathes offer amazing options like adjustable speeds and multiple tooling setups. They help create detailed knurls that fit specific needs. Customized patterns become easier to achieve.

Benefits of using CNC lathes:

- High precision

- Customizable patterns

- Efficient production

Innovative methods lead to exciting designs. Metal lathe knurling creates patterns suited for different projects. With these advanced techniques, makers can turn their ideas into reality, combining art and technology. Why settle for ordinary when you can create something extraordinary?

Resources for Further Learning

Recommended books, videos, and online courses on knurling. Community forums and organizations for metalworking enthusiasts.Learning about metal lathe knurling can be fun! Here are some great resources to check out:

- **Books:** Search for titles on machine tools and metalworking techniques at your library.

- **Videos:** YouTube has many tutorials showing knurling steps and tips.

- **Online Courses:** Websites like Coursera or Udemy offer courses on machining.

- **Forums:** Join metalworking communities on Reddit or Facebook to share ideas.

- **Organizations:** Look for local maker spaces or clubs focused on metalworking.

These resources will help you get better at your knurling projects!

What are good resources to learn about knurling techniques?

Some great resources include books, YouTube videos, and online courses. Joining community forums can also connect you with experienced metalworkers.

Conclusion

In summary, controlling the knurling depth on a metal lathe is essential for achieving precise patterns. You can adjust the tool’s position to get the right depth. Understanding this concept helps improve your machining skills. If you want to learn more, check out tutorials or practice on your lathe. With time and effort, you will master this important technique!FAQs

What Are The Common Methods For Adjusting The Knurling Depth On A Metal Lathe?To adjust the knurling depth on a metal lathe, you can do a few simple things. First, change the pressure on the knurling tool by twisting a knob. Second, move the tool closer or farther from the metal. Third, you can switch to a different knurling tool if needed. Each of these methods helps make the grooves deeper or shallower.

How Does The Choice Of Knurling Wheel Affect The Depth And Quality Of The Knurling Process?The knurling wheel is very important. If you choose a wheel with deep patterns, it makes bigger grooves on the surface. This gives you a rougher feel. A wheel with smooth patterns creates shallower grooves, making the surface nicer to touch. Picking the right wheel helps you get the depth and quality you want.

What Are Some Troubleshooting Tips For Achieving Consistent Knurling Depth During Machining?To get a smooth and even knurling depth, make sure the tool is sharp and clean. Check that the workpiece is securely held in place. Adjust the pressure you use when pressing the tool against the metal. You can also try changing the speed of the machine for better results. Lastly, always keep an eye on how deep the tool is cutting.

How Can You Measure The Depth Of Knurling Accurately On Finished Parts?You can measure the depth of knurling by using a special tool called a depth gauge. Place the gauge in the grooves of the knurling. Make sure it fits snugly. Then, read the measurement on the gauge. This will tell you how deep the knurling is.

What Materials And Feed Rates Are Recommended For Optimal Knurling Depth On Different Types Of Metals?For knurling, softer metals like aluminum work best with a slower feed rate. You can use a medium feed rate for steel and brass. Harder metals, like stainless steel, need a faster feed rate for good depth. Always use the right tool for the metal type. This way, you get nice, clear patterns on the surface.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Methods For Adjusting The Knurling Depth On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the knurling depth on a metal lathe, you can do a few simple things. First, change the pressure on the knurling tool by twisting a knob. Second, move the tool closer or farther from the metal. Third, you can switch to a different knurling tool if needed. Each of these methods helps make the grooves deeper or shallower.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Knurling Wheel Affect The Depth And Quality Of The Knurling Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The knurling wheel is very important. If you choose a wheel with deep patterns, it makes bigger grooves on the surface. This gives you a rougher feel. A wheel with smooth patterns creates shallower grooves, making the surface nicer to touch. Picking the right wheel helps you get the depth and quality you want.”}},{“@type”: “Question”,”name”: “What Are Some Troubleshooting Tips For Achieving Consistent Knurling Depth During Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a smooth and even knurling depth, make sure the tool is sharp and clean. Check that the workpiece is securely held in place. Adjust the pressure you use when pressing the tool against the metal. You can also try changing the speed of the machine for better results. Lastly, always keep an eye on how deep the tool is cutting.”}},{“@type”: “Question”,”name”: “How Can You Measure The Depth Of Knurling Accurately On Finished Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can measure the depth of knurling by using a special tool called a depth gauge. Place the gauge in the grooves of the knurling. Make sure it fits snugly. Then, read the measurement on the gauge. This will tell you how deep the knurling is.”}},{“@type”: “Question”,”name”: “What Materials And Feed Rates Are Recommended For Optimal Knurling Depth On Different Types Of Metals? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For knurling, softer metals like aluminum work best with a slower feed rate. You can use a medium feed rate for steel and brass. Harder metals, like stainless steel, need a faster feed rate for good depth. Always use the right tool for the metal type. This way, you get nice, clear patterns on the surface.”}}]}