Imagine working on a metal lathe and trying to get each piece just right. It feels like solving a puzzle, doesn’t it? Every tiny turn matters. This is where a micrometer stop setup can help. Have you ever wondered how machinists get those perfect cuts every time?

Well, let me take you on a journey into the world of metalworking magic. Picture a tool that ensures every piece is the perfect fit, like a key in a lock. Surprise—this is what a micrometer stop does!

Did you know that even tiny mistakes in measurements can cause big headaches? That’s why knowing how to set up a micrometer stop is super important. Whether you’re new to lathes or a budding expert, this handy tool keeps your work spot on.

Setting Up A Metal Lathe Micrometer Stop: A Guide

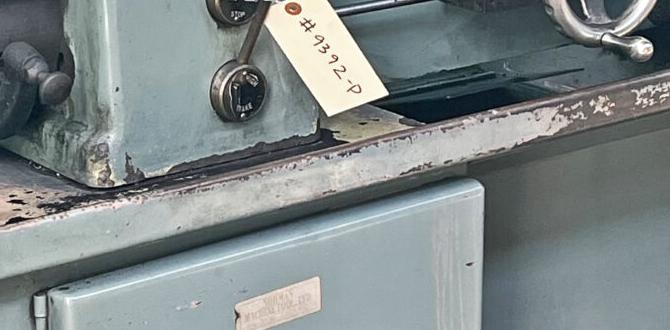

Metal Lathe Micrometer Stop Setup

Ever tried stopping a train with just a finger? Setting up a metal lathe micrometer stop feels like that sort of magical precision! This tool helps machinists control each cut with pinpoint accuracy. Imagine crafting tiny parts where even a hair’s width matters. With the micrometer stop, you can easily repeat these cuts. It becomes your trusty sidekick, ensuring every piece fits perfectly, like pieces of a puzzle coming together just right.Understanding Micrometer Stops

Definition and purpose of micrometer stops. Importance in precision machining and metalworking.A micrometer stop is a special tool used in machining. It helps measure and control small distances with great accuracy. This is very important in metalworking. It ensures that parts are made the right size.

Here are some key points about micrometer stops:

- Definition: A micrometer stop sets precise limits.

- Purpose: It makes sure every cut is exact.

- Importance: Precision leads to better fits and stronger parts.

Using a micrometer stop can improve the quality of finished products. Skilled workers depend on it for accurate work. A well-set micrometer stop can save time and reduce waste.

What is the role of a micrometer stop in metalworking?

The micrometer stop plays a crucial role in metalworking by ensuring every measurement is exact. This helps in producing high-quality parts. Accuracy is key for successful machining and reducing errors.

Components of a Metal Lathe Micrometer Stop

Detailed description of essential components. Materials used in construction and their impact on performance.A metal lathe micrometer stop has key parts that help it work well. These components ensure measurements are accurate. Common parts include:

- The base provides stability and keeps everything in place.

- The stop rod is adjustable, allowing users to set the depth easily.

- The micrometer measures small distances precisely, making it vital for fine adjustments.

- Constructed from high-quality steel, these parts offer durability and better performance.

Choosing good materials improves the micrometer stop’s lifespan and accuracy. Using weaker materials can lead to problems like rust and wear.

What materials are used in metal lathe micrometer stops?

Common materials include high-carbon steel for strength and stability. Aluminum can be used for lightweight options. These materials affect how well the tool performs and lasts over time.

How to Choose the Right Micrometer Stop for Your Lathe

Key specifications to consider (size, range, accuracy). Comparison of popular brands and models.Choosing the right micrometer stop for your lathe is important. Think about key specifications first. Consider size, range, and accuracy. Different tasks need different stops. Some well-known brands include:

- Mitutoyo: Known for accuracy and durability.

- Insize: Offers good features at a fair price.

- Starrett: Great reliability and precise measurements.

Keep these factors in mind, and you’ll make a smart choice!

What key specifications should you consider?

Look at size, range, and accuracy. Size affects how well the stop fits your lathe. Range shows what measurements the stop can handle. Accuracy tells you how close the measurements are to the actual size.

Step-by-Step Guide to Setting Up a Micrometer Stop

Preparation and necessary tools. Detailed instructions for installation and adjustment.To set up a micrometer stop, you need some important tools. First, gather a metal lathe, a micrometer stop, a wrench, and a ruler. These will help you with every step. Next, follow these steps:

- Attach the micrometer stop to the lathe rail.

- Use the wrench to secure it tightly.

- Adjust the stop to the right measurement with the ruler.

- Test it by running the lathe briefly.

Check that everything moves smoothly. With careful preparation and these simple steps, you’ll have a micrometer stop ready for use!

What is a micrometer stop used for?

A micrometer stop helps make precise cuts on a metal lathe. It ensures that parts are the same length and improves your accuracy. This tool is essential for quality work in machining.

Related tips to improve setup:

- Always keep your tools clean.

- Double-check your measurements.

- Practice with scrap material first.

Common Mistakes to Avoid During Setup

List of frequent errors and their consequences. Tips for ensuring proper alignment and functionality.Setting up your lathe can be tricky. Many people make small mistakes that lead to big problems. Not aligning the micrometer correctly can cause inaccuracies in your work. Forgetting to tighten screws can turn your lathe into a rickety roller coaster! Always check your alignment; a little twist can make a huge difference. Here’s a quick table of common blunders:

| Error | Consequence |

|---|---|

| Skewed Alignment | Leads to incorrect measurements |

| Loose Parts | Results in vibrations and uneven cuts |

| Poor Tool Selection | Can ruin material and waste time |

Always double-check before starting your work. Remember, a well-set lathe means smoother cutting—a happy workshop is a productive workshop!

Maintaining Your Micrometer Stop for Longevity

Routine cleaning and care practices. Signs of wear and when to replace parts.Keeping your micrometer stop in good shape is like giving it a spa day! Start by cleaning it regularly. Dust and grime can sneak in and mess things up. Use a soft cloth and some gentle cleaner. Look for signs of wear, like scratches or looseness. If any part seems worn out, it’s time for a change. Remember, a happy micrometer means happy metal lathe work!

| Routine Care | Signs of Wear | Action Needed |

|---|---|---|

| Clean regularly | Visible scratches | Replace the part |

| Check for rust | Loose components | Tighten or replace |

Applications of Micrometer Stops in Metalworking

Various machining tasks where micrometer stops excel. Case studies of effective micrometer stop usage.Micrometer stops help in many metalworking tasks. They make cutting parts easier and more precise. Here are some applications where they shine:

- Measuring lengths: Micrometer stops ensure cuts are the same length each time.

- Drilling: They provide exact depths for holes.

- Turning: Micrometer stops help create uniform shapes in metal lathes.

In one case, a machinist reduced errors by 30% using micrometer stops on a lathe. They made the setup faster and more accurate.

What are real-world examples of micrometer stops in use?

They are used in many workshops to speed up tasks and improve quality. By keeping measurements consistent, machinists save time and reduce waste. Their use leads to better results in metal parts.

Advanced Techniques for Enhanced Precision

Integrating additional tools for improved accuracy. Tips for experienced users looking to refine their setup.To enhance accuracy, experienced users can add special tools to their metal lathe setup. These tools help measure and adjust with high precision. Here are some tips to refine your setup:

- Use a dials caliper for better measurements.

- Add tool holders for faster tool changes.

- Check machine alignment often for consistent results.

- Incorporate digital readouts for easier tracking.

These improvements can lead to better projects and save you time!

What are some important tools for metal lathe accuracy?

Essential tools include dials caliper, digital readouts, and tool holders. They help in achieving greater precision while working. Using these tools provides better control over measurements and adjustments.

FAQs about Metal Lathe Micrometer Stops

Common questions and expert answers. Troubleshooting tips for common issues.Many people have questions about metal lathe micrometer stops. Here are some common ones with answers to help you.

What is a micrometer stop used for?

A micrometer stop helps you make precise cuts on a lathe. It stops the tool at a set position, ensuring accuracy.

How do I set it up?

First, attach it to the lathe. Next, adjust the micrometer to the desired measurement. Then, test it with a piece of scrap material.

What if it doesn’t stop correctly?

- Check if it’s tightened properly.

- Make sure the micrometer is set to the right number.

- Inspect for any damage or wear.

With these tips, you can easily troubleshoot common issues. A micrometer stop can greatly improve your metal lathe projects.

Conclusion

Setting up a micrometer stop on a metal lathe is crucial. It ensures precise, repeatable cuts for your projects. Always measure carefully and adjust accurately to avoid errors. Practice regularly to improve your skills. Explore more about lathe techniques in books or online videos to enhance your understanding and become a better machinist.FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Micrometer Stop Setup:Sure! A micrometer stop is a tool for measuring how much we move our metal lathe. It helps us make precise cuts. To set it up, first, we need to attach it to the lathe. Then, we can adjust it to the correct size. Finally, we lock it in place so it stays put while we work.

Sure! Just let me know what question you want me to answer, and I’ll be happy to help you with a simple response.

What Is The Purpose Of A Micrometer Stop In A Metal Lathe Setup?A micrometer stop helps you make precise measurements when cutting metal on a lathe. It acts like a ruler that you set in place. When you turn the lathe, the micrometer stop makes sure the cutting tool stops exactly where you want. This gives you better control and keeps your work neat and accurate.

How Do You Properly Calibrate A Micrometer Stop For Accurate Depth Measurements?To calibrate a micrometer stop, you first need to set it on a flat surface. Next, you carefully turn the micrometer screw until it touches the surface without pushing too hard. Then, check the reading on the scale; it should show zero. If it doesn’t, adjust it until it does. Now, you’re ready to measure depth accurately!

What Are The Steps To Install A Micrometer Stop On A Lathe, And What Tools Are Required?To install a micrometer stop on a lathe, first, you need some tools: a wrench, a screwdriver, and the micrometer stop itself. First, turn off the lathe and unplug it for safety. Next, find where to attach the micrometer stop on the lathe. Use the wrench to tighten any screws needed. Finally, double-check that the stop is secure, then plug the lathe back in and test it out!

How Can A Micrometer Stop Improve Repeatability And Precision In Machining Operations?A micrometer stop is a tool that helps you measure exact distances in machining. When you use it, you can get the same measurement every time. This means your pieces will fit together better. It makes your work more accurate and saves time, too!

What Common Mistakes Should Be Avoided When Setting Up A Micrometer Stop On A Metal Lathe?When you set up a micrometer stop on a metal lathe, avoid a few mistakes. First, make sure it’s tight so it doesn’t move. Second, check that it is level and straight; this helps get good cuts. Remember to measure twice before you start cutting; measure once can lead to mistakes. Lastly, always keep your hands and face away from spinning parts for safety.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Micrometer Stop Setup:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A micrometer stop is a tool for measuring how much we move our metal lathe. It helps us make precise cuts. To set it up, first, we need to attach it to the lathe. Then, we can adjust it to the correct size. Finally, we lock it in place so it stays put while we work.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer, and I’ll be happy to help you with a simple response.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Micrometer Stop In A Metal Lathe Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A micrometer stop helps you make precise measurements when cutting metal on a lathe. It acts like a ruler that you set in place. When you turn the lathe, the micrometer stop makes sure the cutting tool stops exactly where you want. This gives you better control and keeps your work neat and accurate.”}},{“@type”: “Question”,”name”: “How Do You Properly Calibrate A Micrometer Stop For Accurate Depth Measurements?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate a micrometer stop, you first need to set it on a flat surface. Next, you carefully turn the micrometer screw until it touches the surface without pushing too hard. Then, check the reading on the scale; it should show zero. If it doesn’t, adjust it until it does. Now, you’re ready to measure depth accurately!”}},{“@type”: “Question”,”name”: “What Are The Steps To Install A Micrometer Stop On A Lathe, And What Tools Are Required?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a micrometer stop on a lathe, first, you need some tools: a wrench, a screwdriver, and the micrometer stop itself. First, turn off the lathe and unplug it for safety. Next, find where to attach the micrometer stop on the lathe. Use the wrench to tighten any screws needed. Finally, double-check that the stop is secure, then plug the lathe back in and test it out!”}},{“@type”: “Question”,”name”: “How Can A Micrometer Stop Improve Repeatability And Precision In Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A micrometer stop is a tool that helps you measure exact distances in machining. When you use it, you can get the same measurement every time. This means your pieces will fit together better. It makes your work more accurate and saves time, too!”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Be Avoided When Setting Up A Micrometer Stop On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you set up a micrometer stop on a metal lathe, avoid a few mistakes. First, make sure it’s tight so it doesn’t move. Second, check that it is level and straight; this helps get good cuts. Remember to measure twice before you start cutting; measure once can lead to mistakes. Lastly, always keep your hands and face away from spinning parts for safety.”}}]}