Have you ever seen a metal lathe in action? It’s a fascinating machine that shapes metal into useful parts. But did you know that tuning the motor speed of a metal lathe can make a big difference?

Adjusting the motor speed helps you cut and shape metal more evenly. It can also save you time in the workshop. Think about it: Who wouldn’t want a machine that works faster and better?

Many hobbyists and professionals use a metal lathe. Yet, not everyone knows how to tune it correctly. You might be surprised by how easy it is to improve your lathe’s performance. Imagine being able to make perfect parts just by tweaking one thing!

In this article, we’ll explore the art of metal lathe motor speed tuning. You’ll discover tips that can transform your projects. Get ready to learn how a few simple changes can make your metalworking experiences even better!

Metal Lathe Motor Speed Tuning: A Comprehensive Guide

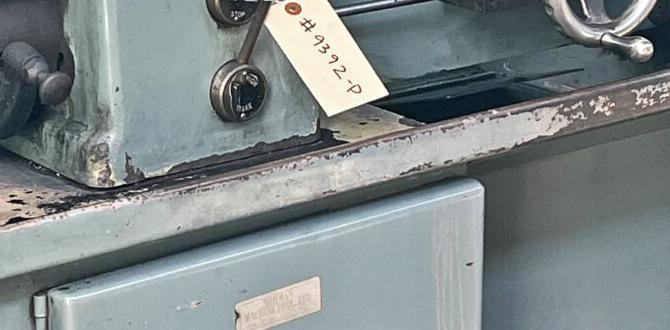

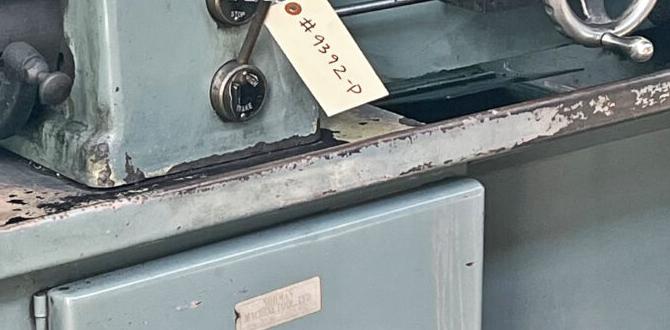

Metal Lathe Motor Speed Tuning

Metal lathe motor speed tuning is vital for accurate machining. Adjusting motor speed enhances performance and extends tool life. Did you know that running at the wrong speed can cause poor finishes or damages? By choosing the right RPM (revolutions per minute), you can achieve better results on different materials. Consider testing various speeds for your projects. This tuning not only boosts productivity but also makes your work safer and more enjoyable.Understanding Metal Lathe Motor Speed

Explanation of motor speed in metal lathes. Importance of tuning motor speed for various applications.Motor speed in metal lathes is key for many tasks. It helps shape metal properly. Each project needs a different speed. Tuning speeds lets you cut more smoothly and accurately. Here’s why it matters:

- Fine tuning: Achieves better results.

- Material matching: Different metals require different speeds.

- Safety: Correct speed lowers risks.

- Tool life: Proper speed extends tool lifespan.

Why is tuning motor speed important?

Tuning motor speed helps achieve precise cuts and safer operation. Adjusting speed lets you work with various materials better, ensuring quality and efficiency.

Tools Needed for Speed Tuning

List of essential tools for tuning motor speed. Recommendations for measurement devices (e.g., tachometers).To tune the speed of a metal lathe motor, you need some key tools. Having the right equipment makes it easier to get accurate results. Here’s a list of essential tools:

- Tachometer: Measures the motor’s speed accurately.

- Multimeter: Tests electrical characteristics.

- Adjustable wrench: Helps with tightening and loosening parts.

- Machine oil: Lubricates the motor for smooth operation.

Using these tools will make your speed tuning effective and safe.

What tools are best for measuring motor speed?

The best tool for measuring motor speed is a tachometer. It gives you exact RPM readings, which helps ensure your lathe runs smoothly. Other useful tools include digital multimeters for checking electrical values. Having the right tools makes maintenance easier.

Step-by-Step Tuning Process

Detailed steps for adjusting motor speed on different lathe models. Common adjustments and settings to consider.To adjust the motor speed on different lathe models, follow these simple steps:

- Check the power supply. Make sure it’s plugged in and working.

- Look for the speed control dial. This is usually on the front panel.

- Rotate the dial to set the desired speed. Start slow and increase gradually.

- Observe the lathe. Listen for any unusual sounds during operation.

- For specific models, refer to the manual for special adjustments.

Common settings to keep in mind are torque, belts, and pulley sizes. Fine-tuning these can optimize performance.

How can I determine the right speed for my lathe?

Choose the speed based on the material you are using. For example, soft materials need lower speeds, while hard materials need higher speeds. Always check your lathe’s manual for the best guidelines!

Troubleshooting Speed Issues

Identifying common symptoms of speedrelated problems. Solutions for specific tuning challenges encountered.Speed issues in metal lathes can make your work frustrating. Common signs include strange noises, stalling, or inconsistent speeds. These problems can stem from a few reasons. To fix speed challenges:

- Check the motor belt for wear.

- Examine the power supply for strong connections.

- Calibrate the speed settings regularly.

Keeping an eye on these areas helps keep your lathe running smoothly.

What should I do if my lathe is slowing down?

Check for any loose parts or worn belts first. Tightening them can often solve the issue.

Can I tune my lathe’s motor speed easily?

Yes! Regular maintenance and adjustments can keep your lathe’s speed at its best.

Maintaining Optimal Motor Performance

Best practices for ongoing maintenance after tuning. Tips on monitoring motor health and performance.To keep your lathe motor purring like a kitten after tuning, stick to some best practices. Regularly check the motor for dust and debris; a clean machine runs smoother. Monitor the vibrations; if it shakes like it’s in a dance-off, something might be wrong. Keep an eye on the temperature, too; too hot means trouble! Here’s a quick table to help you remember:

| Maintenance Task | Frequency |

|---|---|

| Clean motor | Weekly |

| Check vibrations | Every session |

| Monitor temperature | Every session |

With these tips, you’ll keep your motor in top shape. Remember, a well-maintained lathe is a happy lathe!

Advanced Techniques for Experienced Users

Exploration of sophisticated tuning methods and modifications. Benefits of custom setups for specialized tasks.For skilled users, fine-tuning a metal lathe offers exciting possibilities. Advanced techniques allow for precise adjustments that enhance performance. Modifying settings can lead to better results for specific tasks. Here are some of the benefits:

- Increased accuracy in cuts and shapes.

- Improved surface finish on projects.

- Faster production times for specialized tasks.

Custom setups create unique advantages. You can adapt your lathe for different materials. This flexibility boosts creativity and efficiency in your work.

What are some advanced tuning methods?

Advanced tuning methods include adjusting the motor speed, changing gear ratios, and using performance-enhancing accessories. These changes help optimize the lathe for various tasks.

Safety Considerations During Tuning

Essential safety measures to take when tuning motor speed. Proper use of safety equipment and precautions.Tuning your lathe motor speed is exciting, but safety should be your number one priority. First, always wear your safety goggles. Flying metal bits are not a fashion statement! Next, use gloves but make sure they are not too loose. We don’t want to give the lathe an unexpected hug. Keep your workspace tidy. A clean area helps avoid accidents. Here’s a handy table of safety tips:

| Safety Gear | Purpose |

|---|---|

| Goggles | Protect your eyes from debris. |

| Gloves | Keep hands safe but fitted. |

| Ear Protection | Reduce noise exposure. |

| Dust Mask | Avoid inhaling harmful particles. |

Don’t forget to check your tools before starting. Malfunctioning gear is like a cat with a bad attitude—it can cause real trouble!

Conclusion

In summary, tuning your metal lathe motor speed is essential for better performance. Start by checking your motor specifications and adjusting the speed settings. This ensures smooth operations and precise cuts. Remember, practice makes perfect! Explore more resources or guides to deepen your understanding. With patience, you’ll master speed tuning and improve your projects significantly. Happy lathe turning!FAQs

What Factors Should Be Considered When Determining The Optimal Motor Speed For A Metal Lathe Operation?When choosing the best speed for a metal lathe, you should think about the type of metal. Some metals are soft and cut easily, while others are hard and need slower speeds. You also need to consider the size of the tool you’re using. Bigger tools usually work better at slower speeds. Lastly, think about how smooth you want the cut to be; faster speeds can make rough cuts.

How Can You Effectively Adjust The Motor Speed On A Metal Lathe For Different Materials And Tooling Requirements?To adjust the motor speed on a metal lathe, first check the material you are using. Softer metals, like aluminum, need faster speeds. Harder metals, like steel, need slower speeds. You can usually adjust the speed using a dial or switch on the lathe. Always remember to start slow and then change the speed based on how the tool cuts.

What Are The Pros And Cons Of Using Variable Frequency Drives (Vfds) For Tuning The Motor Speed On A Metal Lathe?Using Variable Frequency Drives (VFDs) for adjusting motor speed on a metal lathe has some good and bad sides. One good thing is that VFDs help you change the speed smoothly, which can make your work more accurate. They also save energy, so you spend less money on electricity. On the downside, VFDs can be more expensive to buy and fix. They can also make your machine more complicated to use at first.

How Can Excessive Or Insufficient Motor Speed Impact The Quality Of The Finished Workpiece In Lathe Machining?If the motor speed is too fast, parts can get too hot. This can make them melt or get damaged. If the speed is too slow, the workpiece might not be shaped right or take too long. Both problems can ruin the final product. You want just the right speed for the best results!

What Methods Can Be Employed To Accurately Measure And Monitor The Motor Speed Of A Metal Lathe During Operation?You can measure the motor speed of a metal lathe using a few easy methods. One way is to use a tachometer, which is a tool that shows how fast the motor is spinning. Another method is to attach a sensor that counts how many times the motor turns in a minute. Finally, you can also use a digital readout that shows the speed on a screen. These tools help you keep track of the motor speed while you work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Factors Should Be Considered When Determining The Optimal Motor Speed For A Metal Lathe Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the best speed for a metal lathe, you should think about the type of metal. Some metals are soft and cut easily, while others are hard and need slower speeds. You also need to consider the size of the tool you’re using. Bigger tools usually work better at slower speeds. Lastly, think about how smooth you want the cut to be; faster speeds can make rough cuts.”}},{“@type”: “Question”,”name”: “How Can You Effectively Adjust The Motor Speed On A Metal Lathe For Different Materials And Tooling Requirements? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the motor speed on a metal lathe, first check the material you are using. Softer metals, like aluminum, need faster speeds. Harder metals, like steel, need slower speeds. You can usually adjust the speed using a dial or switch on the lathe. Always remember to start slow and then change the speed based on how the tool cuts.”}},{“@type”: “Question”,”name”: “What Are The Pros And Cons Of Using Variable Frequency Drives (Vfds) For Tuning The Motor Speed On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using Variable Frequency Drives (VFDs) for adjusting motor speed on a metal lathe has some good and bad sides. One good thing is that VFDs help you change the speed smoothly, which can make your work more accurate. They also save energy, so you spend less money on electricity. On the downside, VFDs can be more expensive to buy and fix. They can also make your machine more complicated to use at first.”}},{“@type”: “Question”,”name”: “How Can Excessive Or Insufficient Motor Speed Impact The Quality Of The Finished Workpiece In Lathe Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the motor speed is too fast, parts can get too hot. This can make them melt or get damaged. If the speed is too slow, the workpiece might not be shaped right or take too long. Both problems can ruin the final product. You want just the right speed for the best results!”}},{“@type”: “Question”,”name”: “What Methods Can Be Employed To Accurately Measure And Monitor The Motor Speed Of A Metal Lathe During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can measure the motor speed of a metal lathe using a few easy methods. One way is to use a tachometer, which is a tool that shows how fast the motor is spinning. Another method is to attach a sensor that counts how many times the motor turns in a minute. Finally, you can also use a digital readout that shows the speed on a screen. These tools help you keep track of the motor speed while you work.”}}]}