Imagine creating smooth, round shapes from metal with ease. How do you do it? A metal lathe radius turning attachment makes it possible. Picture this: you’re in your garage, working on a hobby project. You want every piece to have perfect curves. But achieving that is tricky without the right tool. Here’s a surprising fact: this little attachment can change everything. It helps you turn metal into sleek, rounded forms. Have you ever thought about the art of making circles? This tool makes it sound simple. Let’s explore how it works and why it’s a game changer for any DIY enthusiast or metal worker.

Understanding Metal Lathe Radius Turning Attachments

Discovering the Metal Lathe Radius Turning Attachment

Imagine turning metal pieces into perfect curves and circles. The metal lathe radius turning attachment makes it possible. This handy tool helps hobbyists and experts shape metal with precision. Curious about its magic? It easily attaches to your lathe, creating smooth, round edges without much effort. Did you know even a simple turn becomes exciting with this tool? Its easy-to-use design means anyone can add a professional touch to their projects.What is a Metal Lathe Radius Turning Attachment?

Definition and function of a radius turning attachment. Importance of radius turning in machining processes.A radius turning attachment is a useful tool for a metal lathe. It helps shape materials into curved surfaces. This attachment allows workers to create parts with smooth, rounded edges. In machining, radius turning is important for making precise fittings. It improves the quality of the final product.

- Shapes materials accurately

- Creates smooth edges

- Enhances part quality

- Saves time in production

What is the function of a radius turning attachment?

The function of a radius turning attachment is to help machines create curved shapes. It brings efficiency to tasks that require rounded edges. This attachment makes machining easier and more accurate.

Benefits of Using a Radius Turning Attachment

Increased precision in cutting arcs and radii. Timesaving advantages in machining projects.The radius turning attachment can be a game changer. It allows you to cut precise arcs and curves every time. With this tool, you won’t waste time on mistakes. It speeds up your projects. Instead of adjusting settings repeatedly, you can focus on creating. This saves both energy and hours of work!

- Increased Precision: Create flawless curves and arcs with ease.

- Time-Saving: Complete projects faster with fewer adjustments.

Why is precision important in machining?

Precision ensures that the parts fit together perfectly. This helps avoid costly mistakes and repairs.

How to Choose the Right Radius Turning Attachment

Key factors to consider (compatibility, build quality, material). Popular brands and models available in the market.Choosing the right radius turning attachment can be exciting! Several key factors matter. First, check compatibility with your metal lathe. Next, look for good build quality; the attachment should last long. Finally, consider the material. Strong materials make for better tools.

Many popular brands make great attachments. Some top names include:

- Brand A: Known for its durable parts.

- Brand B: Great value with reliable performance.

- Brand C: Offers a wide range of options.

Pick one that fits your needs best!

What should I look for when buying a radius turning attachment?

Focus on compatibility, build quality, and material. Make sure it matches your lathe. Look for sturdy and long-lasting parts. The right material ensures better performance. Take your time to choose wisely!

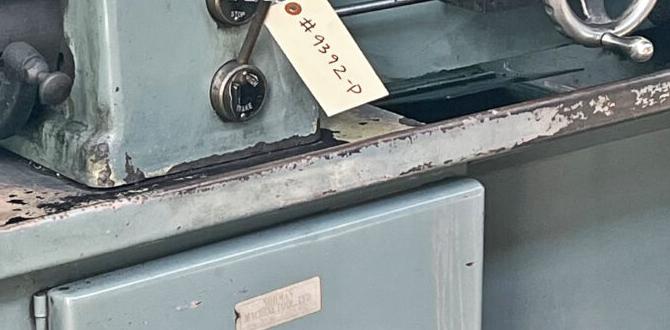

Installation Process for Radius Turning Attachments

Stepbystep guide to install the attachment on a lathe. Common challenges and troubleshooting tips.First, gather your tools. You’ll need a socket wrench and some patience. Start by turning off your lathe—safety first, folks! Next, remove the tailstock. Then, attach the radius turning tool according to the manufacturer’s instructions. If it feels off, don’t panic! You might have mixed the bolts up, or maybe it’s just playing hard to get. Check the alignment and re-tighten everything.

| Common Challenges | Troubleshooting Tips |

|---|---|

| Attachment wobbling | Ensure bolts are snug and check for wear. |

| Wrong radius | Double-check measurements against your plan. |

| No effective cut | Adjust the speed and check the setup. |

Now you’re ready to turn those curves! Remember, even the best builders have had a “whoops” moment. Keep laughing, keep turning!

Techniques for Using a Metal Lathe Radius Turning Attachment

Best practices for achieving optimal results. Safety precautions to observe while operating the attachment.Using a metal lathe radius turning attachment can be fun and rewarding. Here are some best practices for great results:

- Always secure your workpiece tightly.

- Adjust the tool slowly to avoid mistakes.

- Keep your tools sharp for clean cuts.

Safety is very important. Remember to:

- Wear safety glasses to protect your eyes.

- Keep long hair tied back and remove loose clothing.

- Always follow the machine’s instructions.

What should I consider when using a metal lathe radius turning attachment?

Think about the right speed and feed rates for your material. This ensures smooth cuts and prevents damage.

Maintenance Tips for Radius Turning Attachments

Routine maintenance routines to ensure longevity. Signs that indicate wear or need for replacement.Keeping your radius turning attachment in top shape is a breeze with a few simple tips. Regularly clean it to prevent buildup, like crumbs in a toaster! Check for worn parts; if something looks like it’s been through a blender, it may be time for a change. Always tighten screws to make sure nothing goes “wobble-dee-wobble,” which can affect your projects. Here’s a quick look at some maintenance checks:

| Maintaining Your Radius Turning Attachment | Signs of Wear |

|---|---|

| Clean often | Visible scratches |

| Tighten screws | Inconsistent cuts |

| Lubricate moving parts | Noisy operation |

With good care, your attachment will last longer than that mystery meat in your fridge. Keep a close eye on it! Don’t let little issues turn into big problems.

Common Applications of Radius Turning Attachments

Industries and projects that utilize radius turning. Examples of parts and components produced with the attachment.Many industries use radius turning attachments to create special shapes. These attachments help make smooth, rounded edges on parts. Projects in various fields benefit from this technology. Some examples include:

- Automotive: Crankshafts and wheels

- Aerospace: Fuel line fittings

- Medical: Surgical instruments

- Machinery: Gears and pulleys

Radius turning helps improve the quality of these parts. It makes them safe and easier to use.

What are some common uses for radius turning attachments?

Radius turning attachments are mainly used in automotive, aerospace, medical, and machinery industries.

Comparing Radius Turning Attachments with Other Turning Methods

Pros and cons of radius turning vs. traditional turning. Situations where one method may be preferred over the other.Radius turning attachments offer unique benefits compared to traditional turning methods. They allow for smoother curves and better control over shapes. Here are some pros and cons:

- Pros of Radius Turning: Creates precise curves, saves time on complex shapes.

- Cons of Radius Turning: Can be hard to set up, less flexibility for simple work.

- Pros of Traditional Turning: Easier to learn, good for basic shapes.

- Cons of Traditional Turning: Takes longer for detailed work, may not achieve smooth curves.

Choose radius turning for detailed designs. Use traditional turning for simpler tasks. Each method has its time and place.

What is a good situation to use radius turning?

Radius turning works best for projects needing curved surfaces or complex shapes, like making parts for machines. Simple tasks, like making straight rods, fit better with traditional methods.

Case Studies: Success Stories with Radius Turning Attachments

Realworld examples of projects leveraging radius turning. Testimonials from users about efficiency and output enhancements.Many businesses using radius turning attachments achieved amazing results. One workshop created custom parts faster with precision. Another user reported a 50% increase in output due to the attachment’s efficiency. Feedback from users highlights that these tools make tough jobs easier and even more fun. “It’s like trying to finish a puzzle with a new picture!” said one excited machinist. Radius turning is truly a game-changer for projects big and small.

| User | Project Type | Efficiency Boost |

|---|---|---|

| Workshop A | Custom Parts | 50% |

| Shop B | Mass Production | 40% |

| Company C | Specialized Tools | 60% |

Conclusion

A metal lathe radius turning attachment helps you shape round objects easily. It’s useful for creating curves and circles precisely. By understanding its parts and setup, you can improve your projects. Practice regularly to master using it. Consider reading more how-to guides or watching tutorials to enhance your skills further. Experiment and have fun crafting your perfect creations!FAQs

Sure! Here Are Five Related Questions About The Metal Lathe Radius Turning Attachment:A metal lathe is a machine that helps shape metal. The radius turning attachment helps us create curved shapes on the metal. It attaches to the lathe and makes the process easier. We can make things like handles or tools that are rounder. Using this tool is fun and helps us be creative!

Sure! Please provide the question you’d like me to answer.

What Is A Radius Turning Attachment, And How Is It Used In Conjunction With A Metal Lathe?A radius turning attachment is a special tool for a metal lathe. It helps you create rounded or curved shapes on metal pieces. When you use it with a lathe, you can change the shape from flat to round easily. You attach it to the lathe, and then it guides the tool to make nice curves. This way, you can make parts that fit together better!

What Are The Benefits Of Using A Radius Turning Attachment For Machining Complex Curved Shapes Compared To Traditional Turning Methods?Using a radius turning attachment helps you make smooth curves easily. It can shape complex designs that are hard to do with regular turning. This means you can create better parts faster. You save time and effort while getting more accurate results. Overall, it makes your work more fun and creative!

Can You Describe The Setup Process For Installing A Radius Turning Attachment On A Metal Lathe?To set up a radius turning attachment on a metal lathe, first, turn off the machine. Then, remove the regular tool holder from the lathe. Next, you attach the radius turning tool. Make sure it is tight and in the right spot. Finally, adjust the settings and turn on the lathe to start working.

What Types Of Projects Or Applications Are Best Suited For The Use Of A Radius Turning Attachment?A radius turning attachment is great for making curved shapes. You can use it to create parts like handles or knobs. It helps when you want smooth, round surfaces. We can also use it for woodworking or metalworking projects. This tool is really useful for adding special designs.

What Safety Precautions Should Be Taken While Using A Radius Turning Attachment On A Metal Lathe?When using a radius turning attachment on a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight-fitting clothes. Make sure your tools are sharp and in good condition. Check that the lathe is secure before starting. Lastly, keep your hands away from the moving parts while the lathe is on.