Have you ever seen a metal lathe at work? It’s a machine that can transform a metal piece into amazing objects. But wait, did you know that without knowing the metal lathe safety procedures, things can get messy? Imagine a superhero without a cape. They’re strong but need protection. The same goes for those operating a lathe. A strong metal lathe can make magic happen, yet it demands respect and attention.

When my cousin Joe first saw a metal lathe, he thought it looked like a robot. It was turning fast and cutting metal like butter. But Joe noticed something else. The operator wore goggles and gloves. Isn’t it weird to wear so much gear just to work on metal? That’s part of staying safe with a metal lathe!

Why do we need all these safety rules, you ask? The answer is simple. To keep the magic safe. Remember this: the more you learn about metal lathe safety, the more fun you have creating amazing things. Ready to dive into these procedures and keep the wonder alive?

Essential Metal Lathe Safety Procedures: Protect Yourself

Metal Lathe Safety Procedures

Using a metal lathe can be fun and educational, but safety is key! Always wear safety goggles to protect your eyes from flying debris. Keep long hair tied back and avoid loose clothing that can get caught in the machine. Did you know that checking your tools and work area before starting can prevent accidents? Regularly inspect the lathe for any wear or damage. Following these metal lathe safety procedures helps ensure a safe and enjoyable experience for everyone.Personal Protective Equipment (PPE) for Metal Lathe Operation

Description of essential PPE: safety glasses, gloves, and protective clothing. Importance of wearing appropriate footwear and avoiding loose clothing.Operating a metal lathe might sound like crafting metal masterpieces, but safety should be the true hero of the day! Imagine a superhero without their cape—that’s you on a lathe without proper gear. Start with safety glasses; they’re the sidekicks that guard your eyes from flying chips. Next, our trusty duo, gloves and protective clothing, shield your hands and body from potential harm. And those fancy shoes? Yes, sturdy footwear is a must to keep toes safe. Loose clothing is a big no-no; it could turn you into the lathe’s unintentional dance partner!

| PPE Essentials | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris |

| Gloves | Safeguards hands |

| Protective Clothing | Shields body from splinters |

| Sturdy Footwear | Prevents foot injuries |

Your best friend on this journey? Karl Smith, a metal lathe expert, once said, “It’s better to be safe than stylish on the lathe!” Statistics show that proper PPE can reduce accidents by up to 65% in workshops. Let’s make safety as cool as creating art pieces on metal!

Pre-Operation Safety Checks

Steps for inspecting the lathe for damage or wear. Checking and securing workpieces and tools before use.Before you start spinning that metal like a DJ with a new track, a few checks will keep things safe and sound! First, give the lathe a little inspection dance. Look for any wear or damage like scratches or loose bearings. Next, make sure the workpiece and tools are secured tight. They shouldn’t fly off like a superhero cape! If they’re wiggly, tighten those screws. Here’s a handy table to guide your inspection:

| Check | What to Do |

|---|---|

| Lathe Condition | Look for cracks or loose parts |

| Workpiece | Ensure it’s secure and stable |

| Tools | Tighten and check alignment |

Remember, a safe setup is the best setup. It prevents any metal from trying to make a startling exit, stage left! If you follow these simple steps, your metalworking adventure will be smooth and safe. Always be the person who checks twice and spins once. It’s not only smart—it’s fun!

Safe Operation Techniques

Proper posture and positioning to prevent injury. Guidelines for maintaining safe speeds and feeds.Imagine standing straight with your feet apart. This steady stance helps you work safely on a metal lathe. Keeping a good posture prevents back pain. Position your hands and body correctly so you don’t get injured. Always choose the right speed to match the material. Using low speeds for hard metal and higher ones for softer types is smart. Be careful with how you’re feeding the workpiece. Doing this step-by-step keeps you safe and makes the job much easier!

Why is it important to use the right speed on a lathe?

Using the right speed on a lathe helps prevent accidents and ensures a smooth cut. Faster speeds can cause overheating, while slower speeds might create a rough finish.What happens if you use the wrong speed?

Using the wrong speed can lead to tool damage, poor quality work, or even machine failure. This can be dangerous and costly to fix.- Ensure you stand properly to avoid back issues.

- Keep hands and tools at safe distances from moving parts.

- Choose speed based on material type for the best results.

- Maintain focus and check settings often for safety.

“Using a lathe safely is like riding a bike with a helmet. You must stay alert and make smart choices to avoid accidents!”

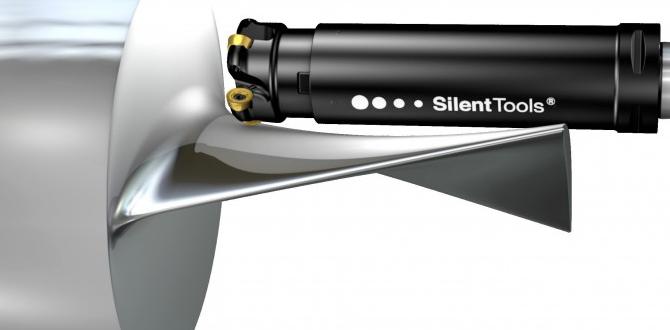

Handling and Using Cutting Tools Safely

Proper techniques for installing and removing cutting tools. Ensuring cutting tools are sharp and functioning correctly.Let’s talk about handling and using cutting tools safely, because nobody wants to lose a finger, right? First, to install or remove a cutting tool, always ensure the machine is completely off. You wouldn’t want it spinning like a merry-go-round. Keep tools sharp, like a ninja’s sword, to avoid accidents. A dull blade is more dangerous than you think! Remember, tools that are sharp and well-maintained are less likely to surprise you in a not-so-fun way.

| Do’s | Don’ts |

|---|---|

| Turn off the machine before tool installation | Leave tools unattended |

| Ensure tools are sharp | Work with dull tools |

And, hey, why not think of your tools like pets? They need a little love and care to function properly too!

Emergency Procedures and Stop Mechanisms

Instructions for using emergency stop buttons and other safety controls. Steps to take in case of an accident or malfunction.Accidents happen, and when they do, knowing how to stop a metal lathe is a lifesaver—literally! Emergency stop buttons are the red superheroes you need. Press these to halt the machine instantly. Now, if something goes haywire, keep calm and follow these steps:

| Step | Action |

|---|---|

| 1 | Hit the emergency stop button |

| 2 | Shout for help! (Alert nearby folks) |

| 3 | Power down the machine safely |

It’s like a dance—only more serious. In case of an injury, seek medical help immediately. Remember, safety controls might not offer punchlines, but they’re your first and best line of defense! Keep cool as a cucumber and stay safe out there!

Maintaining a Safe Work Environment

Importance of keeping the work area clean and organized. Strategies for effective communication and supervision during operations.A clean work area is a safe work area. Keeping the space tidy helps prevent accidents. If everything has a place, there are no surprises. Speaking of surprises, did you know that 27% of workplace accidents happen because of mess? That’s quite a lot!

- Put tools back after use.

- Sweep the floor to remove debris.

- Check that cords do not clutter the floor.

Communication is also key. Always talk to your team before starting. Make sure everyone knows their job. Supervision helps things run smoothly. With clear rules, everyone stays safe.

Why must the work area stay organized?

An organized space stops accidents and boosts work speed. When items are in place, workers find what they need fast. This speeds up tasks and reduces stress. Plus, a tidy area shows trust and respect.

How can communication improve safety?

Good communication clears up confusion. It tells everyone what to do. If something goes wrong, team members can act quickly because they have talked about the plan. This keeps everyone out of harm’s way.

Conclusion

Understanding metal lathe safety is crucial for staying safe. Always wear safety gear and stay alert when using the machine. Keep your workspace clean and follow all instructions carefully. If unsure, ask for help from a knowledgeable person. Remember, safety first! Explore more resources to deepen your knowledge and stay safe while learning about metal lathes.FAQs

What Personal Protective Equipment (Ppe) Should Be Worn When Operating A Metal Lathe To Ensure Safety?When you work with a metal lathe, wear special safety gear. Put on goggles to protect your eyes from flying bits of metal. Wear gloves to keep your hands safe but be sure they don’t get caught in anything. Use earplugs to guard your ears from loud noises. Always wear strong shoes to protect your feet in case something falls.

How Should A Metal Lathe Be Inspected Before Use To Guarantee That It Is In Safe Working Condition?Before using a metal lathe, you should check it carefully. Make sure it is clean and has no loose parts. Look for cracks or any damage. Test the power switch to see if it works. Finally, wear safety gear like goggles to protect your eyes.

What Are The Essential Safety Procedures To Follow When Setting Up And Securing A Workpiece On A Metal Lathe?When working with a metal lathe, always wear safety goggles to protect your eyes. Make sure the workpiece is firmly attached, so it does not move. Keep your fingers away from the spinning parts. Tie back long hair to prevent it from getting caught. Before you start, check that all nuts and bolts are tight.

How Can Operators Minimize The Risk Of Injury During The Operation Of A Metal Lathe, Particularly Concerning Hand Placement And Tool Management?To stay safe on a metal lathe, keep your hands far from any spinning parts. Always use special tools to hold or adjust pieces, not your fingers. Wear safety gloves and goggles to protect your hands and eyes. Double-check that tools are tight and secure so nothing flies off. Remember, being careful helps everyone stay safe while working!

What Steps Should Be Taken In The Event Of An Emergency Or Malfunction While Using A Metal Lathe?If something goes wrong with the metal lathe, switch it off immediately to stop it. Stay calm and move away from the machine. Tell an adult so they can help. Do not try to fix the machine by yourself. Always put safety first and listen to instructions from grown-ups.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Personal Protective Equipment (Ppe) Should Be Worn When Operating A Metal Lathe To Ensure Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you work with a metal lathe, wear special safety gear. Put on goggles to protect your eyes from flying bits of metal. Wear gloves to keep your hands safe but be sure they don’t get caught in anything. Use earplugs to guard your ears from loud noises. Always wear strong shoes to protect your feet in case something falls.”}},{“@type”: “Question”,”name”: “How Should A Metal Lathe Be Inspected Before Use To Guarantee That It Is In Safe Working Condition?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before using a metal lathe, you should check it carefully. Make sure it is clean and has no loose parts. Look for cracks or any damage. Test the power switch to see if it works. Finally, wear safety gear like goggles to protect your eyes.”}},{“@type”: “Question”,”name”: “What Are The Essential Safety Procedures To Follow When Setting Up And Securing A Workpiece On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working with a metal lathe, always wear safety goggles to protect your eyes. Make sure the workpiece is firmly attached, so it does not move. Keep your fingers away from the spinning parts. Tie back long hair to prevent it from getting caught. Before you start, check that all nuts and bolts are tight.”}},{“@type”: “Question”,”name”: “How Can Operators Minimize The Risk Of Injury During The Operation Of A Metal Lathe, Particularly Concerning Hand Placement And Tool Management?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stay safe on a metal lathe, keep your hands far from any spinning parts. Always use special tools to hold or adjust pieces, not your fingers. Wear safety gloves and goggles to protect your hands and eyes. Double-check that tools are tight and secure so nothing flies off. Remember, being careful helps everyone stay safe while working!”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken In The Event Of An Emergency Or Malfunction While Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If something goes wrong with the metal lathe, switch it off immediately to stop it. Stay calm and move away from the machine. Tell an adult so they can help. Do not try to fix the machine by yourself. Always put safety first and listen to instructions from grown-ups.”}}]}