A metal lathe can be a powerful tool for creating various projects. Have you ever wondered how it can make your woodworking or metalworking tasks easier? One important feature is the variable speed setup.

This setup lets you change the speed of the lathe while you work. Imagine being able to adjust your tool’s speed to match the material you’re using. It can make a big difference!

Did you know that a variable speed lathe can help you create smoother finishes? It’s true! When you use just the right speed, your projects can look amazing. This article will guide you through the key points of setting up your metal lathe for variable speed use.

So, whether you’re a beginner or a seasoned pro, you will find tips to enhance your skills. Get ready to dive into the world of metal lathe variable speed setups!

Metal Lathe Variable Speed Setup: A Comprehensive Guide

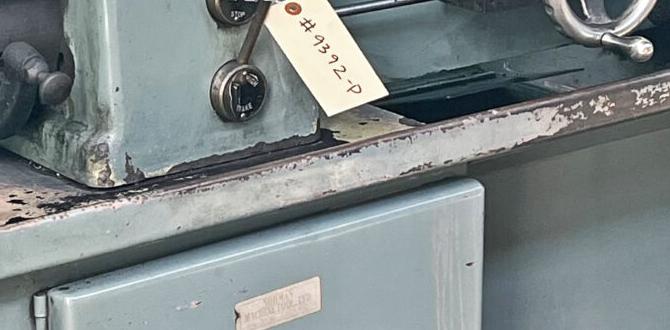

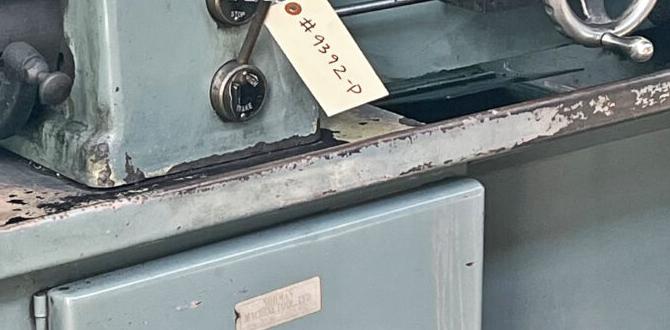

Metal Lathe Variable Speed Setup

Setting up a **metal lathe variable speed** system is key to precision work. First, understand the basics of your lathe. Did you know that different materials need different speeds? Too fast can ruin your work! Adjusting the speed helps achieve smoother cuts, improving your projects. A simple lever or dial often controls this. Learning to change settings can boost your skills. Master this setup, and you’ll be amazed at the quality of your work!Understanding Variable Speed in Metal Lathes

Definition of variable speed and its importance in metalworking.. Types of variable speed mechanisms used in lathes..Variable speed means you can change how fast your metal lathe spins. This is super important in metalworking because it helps you control the tool for different tasks. Think of it like dancing; sometimes you need to slow down for a waltz and speed up for a fast tango!

There are mainly two types of variable speed mechanisms in lathes: mechanical and electronic. Mechanical systems use gears to adjust speed, while electronic systems use motors to do the heavy lifting. Both have their perks and quirks! Below is a quick table to show you more about them:

| Type | Pros | Cons |

|---|---|---|

| Mechanical | Simple and reliable | Can be heavy |

| Electronic | Precise speed control | Higher cost |

Choosing the right mechanism can help make your projects smoother and more fun. Remember, happy lathe, happy metalworker!

Setting Up Your Metal Lathe for Variable Speed

Stepbystep guide on initial setup and adjustments.. Tips for calibrating speed settings for different materials..To set up your metal lathe for variable speed, follow these steps:

- Check your power supply connections.

- Adjust the speed control knob to the desired setting.

- Ensure the lathe is level and stable.

- Test the machine by running it at low speed first.

Calibrating speed settings is important for different materials. For soft metals like aluminum, use a higher speed. For harder metals like steel, lower the speed to avoid damage. Always wear safety gear!

What materials need different speeds on a lathe?

Many materials require different speeds for safe and effective cutting. Soft metals like aluminum work well at high speeds, while hard metals like stainless steel need slower speeds. Adjust accordingly for best results.

Advantages of Using Variable Speed Metal Lathes

Benefits for precision machining and material versatility.. Impact on production efficiency and tool longevity..Using a variable speed metal lathe has many perks! First, it allows for precision machining. This means you can create super accurate parts, making your projects spot-on. Next, it shines with material versatility. From soft plastics to hard metals, this tool handles it all like a champ.

Plus, production efficiency gets a boost. You can switch speeds easily for each task, saving you time. And let’s not forget about tool longevity! Slower speeds can extend tool life, meaning fewer trips to the store. So, you can keep calm and lathe on!

| Benefit | Description |

|---|---|

| Precision Machining | Creates accurate parts |

| Material Versatility | Works with many materials |

| Production Efficiency | Saves time with easy speed changes |

| Tool Longevity | Extends tool life by reducing wear |

Common Issues and Troubleshooting in Variable Speed Setup

Identifying and fixing common setup problems.. Maintenance tips to ensure reliable performance..Common problems can arise in a variable speed setup. First, check the power supply and connections. Loose wires can cause issues. Make sure to tighten them when needed. Also, listen for unusual sounds; they may signal trouble. Regular maintenance helps. Change oil and clean the machine to ensure it runs smoothly.

- Inspect belts for wear.

- Keep the area clean to prevent dust buildup.

- Check speed settings and adjust as required.

A little care goes a long way in keeping your machine reliable!

What are easy ways to troubleshoot my metal lathe?

First, check the power source. Then, listen for strange noises. Lastly, inspect oil levels and clean regularly.

Best Practices for Operating Variable Speed Lathes

Techniques to maximize efficiency and safety during operation.. Recommended speeds for various metals and applications..To run a variable speed lathe safely, follow these tips:

- Always wear safety glasses. Protect your eyes from flying debris.

- Keep your workspace tidy. Clutter can lead to accidents.

- Know the right speed for different metals. For aluminum, use 1000-1500 RPM. For steel, aim for 500-1000 RPM.

- Adjust the speed gradually. Don’t make sudden changes.

Using these practices enhances efficiency. Your projects will go smoothly, keeping you safe and productive!

What are the recommended speeds for various metals?

For aluminum, 1000-1500 RPM is best. For steel, use 500-1000 RPM. For brass, 300-600 RPM works well.

Conclusion

In summary, a metal lathe variable speed setup gives you better control and precision. You can adjust the speed for different materials easily. This setup helps you create smoother and more accurate cuts. We encourage you to explore more about different lathe speeds and practice using them. Hands-on experience will boost your skills and confidence in metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Variable Speed Setup:Sure! A metal lathe is a tool that spins metal to shape it. To set up variable speed, you need to adjust the motor. This lets you change how fast the lathe spins. Faster speeds help with thin pieces, while slower speeds work better for thicker ones. Always be careful and wear safety gear when using it!

Sure! Please share the question you want me to answer, and I’d be happy to help.

What Are The Key Components Of A Variable Speed Setup On A Metal Lathe, And How Do They Function Together?A variable speed setup on a metal lathe has a few key parts. First, there’s a motor that turns the lathe. Then, a control switch helps you change the speed of the motor. There are also belts and pulleys that connect the motor to the lathe, making it run faster or slower. All these parts work together so you can easily adjust how fast the lathe spins.

How Can Adjusting The Variable Speed On A Metal Lathe Improve The Quality Of Machining Operations?Adjusting the speed on a metal lathe can make your work better. When you go slower, you can cut details very carefully. When you go faster, you can finish larger pieces quicker. Finding the right speed helps you make smoother and nicer shapes. This means your projects will look and work better!

What Types Of Motors Are Commonly Used For Variable Speed Drive Systems In Metal Lathes, And What Are Their Advantages?In metal lathes, we often use two types of motors for variable speed drives: DC motors and stepper motors. DC motors are great because they can easily change speed and are simple to control. Stepper motors can move in tiny steps, making them perfect for precise tasks. Both types help us work faster and more accurately while making metal parts.

What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Variable Speed Control System?When using a metal lathe, always wear safety glasses to protect your eyes. Keep your hair and loose clothes away from the machine. Make sure to check that tools are tight and secure before starting. Pay attention to your hands and fingers to avoid getting too close to moving parts. Finally, if something goes wrong, turn off the lathe quickly!

How Does The Choice Of Gear Ratios Impact The Performance Of A Variable Speed Metal Lathe In Different Machining Applications?Gear ratios help us choose how fast or slow a metal lathe spins. When we pick a low gear ratio, the lathe can spin slowly. This is useful for cutting hard metals precisely. If we choose a high gear ratio, it spins faster, which is better for softer materials. So, changing gear ratios helps us do different jobs better!