Have you ever wondered how machines like metal lathes work? They can create amazing shapes from solid metal. But to do this, they need proper wiring. Understanding a metal lathe wiring diagram can help you see the magic behind the scenes. This diagram shows how the wires connect to the parts of the lathe.

Imagine you’re working on a cool project. You want to make something unique, but the machine stops. What if you had the wiring diagram? It could help you fix the issue quickly! Knowing how to read this diagram can save you time and frustration.

Fun fact: Metal lathes have been around for hundreds of years! They started as simple machines but have become more complex. Today, they help hobbyists and professionals alike. Learning about their wiring can empower you to make great things.

Let’s dive into the world of metal lathe wiring diagrams! You’ll discover how these diagrams work and why they are essential for anyone using a lathe.

Understanding Metal Lathe Wiring Diagram For Efficient Use

Discovering the Metal Lathe Wiring Diagram

Understanding the metal lathe wiring diagram is crucial for any DIY enthusiast. A clear wiring diagram shows how to connect wires properly, ensuring the lathe functions safely and efficiently. Did you know that a simple mistake in wiring can cause big problems? Learning to read these diagrams helps avoid errors and boosts confidence in using this tool. With the right knowledge, you can master your metal lathe and tackle exciting projects with ease!What is a Metal Lathe and Its Components?

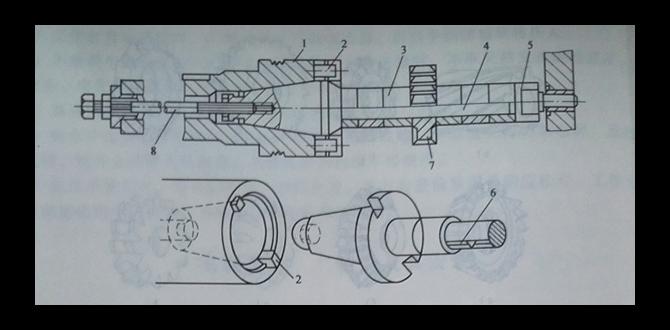

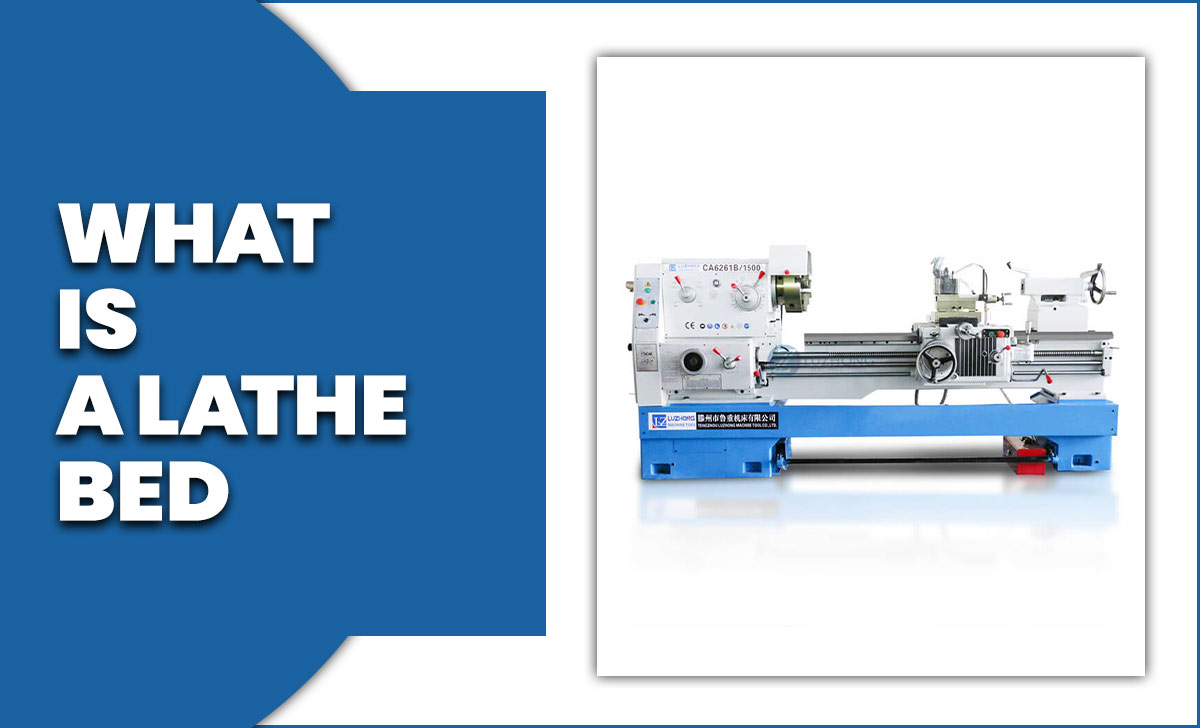

Definition and purpose of a metal lathe. Key components and their functions in machining processes.A metal lathe is a machine that turns metal to shape it into different objects. Think of it as a wizard that can transform a piece of metal into something useful! The main parts of a metal lathe are essential for its magic to happen. Here’s a simple table to explain them:

| Component | Function |

|---|---|

| Headstock | Holds the spindle and motor; it’s like the brain of the lathe. |

| Tailstock | Supports the other end of the metal; it’s the helper buddy! |

| Carriage | Moves the cutting tool; think of it as the magical glove. |

| Bed | Supports the whole machine; imagine the sturdy table that holds a feast! |

These components work together for various machining tasks like cutting and shaping metal. So, next time you see a metal lathe, remember it’s not just a machine; it’s a teamwork superstar!

Importance of Wiring Diagrams in Metal Lathes

Safety considerations and the role of proper wiring. How wiring diagrams facilitate troubleshooting and maintenance.Wiring diagrams in metal lathes are like treasure maps for safety and maintenance. They help everyone stay safe by showing how to connect wires properly. Proper wiring prevents accidents and keeps machines running smoothly, like a well-oiled smile. When things go wrong, these diagrams are lifesavers. They make troubleshooting easier, helping even the most tangled wires feel less knotty. Without these diagrams, mechanics would be lost in a sea of wires!

| Benefits of Wiring Diagrams | Details |

|---|---|

| Safety | Shows correct wire connections |

| Maintenance | Helps identify problems quickly |

| Efficiency | Makes repairs faster |

In short, wiring diagrams are necessary for keeping metal lathes safe and sound. They guide users and techs alike, ensuring everyone can focus on what really matters—turning metal into magic!

Interpreting Metal Lathe Wiring Diagrams

Common symbols and terms used in wiring diagrams. Stepbystep approach to reading and understanding wiring diagrams.Wiring diagrams can seem tricky, but they follow some fun rules! First, get to know common symbols—like wires, switches, and motors. Each symbol tells a different story. Use this simple table to help you:

| Symbol | Description |

|---|---|

| 🌐 | Wire connection |

| 🔌 | Power source |

| 🔄 | Switch |

To understand a wiring diagram, follow these easy steps. First, identify the power source. Next, trace the wires to see how they connect everything. Don’t worry if it seems confusing—like untangling headphones, it just takes patience! Remember, with practice, you’ll be a wiring diagram wizard in no time!

Step-by-Step Guide to Wiring a Metal Lathe

Tools and materials needed for wiring a metal lathe. Detailed process of wiring a metal lathe, from start to finish.Wiring a metal lathe may seem daunting, but it can be a fun project! First, gather your tools. You’ll need a wire stripper, a screwdriver, and some electrical tape. Next, pull out those wires like a magician revealing a rabbit! Follow the wiring diagram closely, connecting each wire to its matching color. Don’t skip this step; colors are your friends! Finally, double-check your connections. One loose wire could make your lathe play hide-and-seek instead of cutting metal. If only it came with an instruction manual for emotions!

| Tools | Materials |

|---|---|

| Wire stripper | Electrical wires |

| Screwdriver | Electrical tape |

| Multimeter | Connectors |

Troubleshooting Common Wiring Issues in Metal Lathes

Identifying common electrical problems and their symptoms. Effective solutions for resolving wiring faults.Troubleshooting wiring issues in a metal lathe can feel like finding a needle in a haystack. Common problems include faulty connections or frayed wires, which can lead to unexpected shutdowns or strange noises. Look out for flickering lights or a machine that won’t start. These are signs that something is off. To fix these pesky faults, check all connections and replace any damaged wires. Remember, a well-wired lathe is a happy lathe!

| Problem | Symptoms | Solution |

|---|---|---|

| Loose Connections | Intermittent operation | Tighten all connections |

| Frayed Wires | Smoke or sparks | Replace damaged wires |

| Short Circuit | No power | Check circuit components |

Best Practices for Maintaining Metal Lathe Wiring

Routine checks and preventive maintenance tips. Importance of using quality components and wiring materials.Keeping a metal lathe’s wiring in top shape is like giving it a warm hug. Regular checks are key! Inspect wires and connections often. A little care can prevent big troubles. Use top-quality parts; using cheap stuff is like putting a band-aid on a broken leg. If you want your lathe to run smoothly, invest in good materials. Remember, a well-maintained lathe is a happy lathe, and happy lathes make happy projects!

| Maintenance Task | Tip |

|---|---|

| Routine Checks | Inspect wiring for wear monthly. |

| Quality Components | Invest in durable wiring materials. |

| Preventive Maintenance | Clean connections to prevent rust. |

Resources for Further Learning on Metal Lathe Wiring

Recommended books, online courses, and forums for metal lathe wiring. List of manufacturers’ resources and technical support options.Learning about metal lathe wiring can be exciting! Here are some great resources to help:

- Books: Look for titles like “Introduction to Metalworking” or “Lathe Projects for Beginners.” These provide step-by-step guidance.

- Online Courses: Websites like Coursera or Udemy offer courses on machining. You can learn at your own pace!

- Forums: Join online communities like Reddit or specific lathe user groups. Ask questions and share tips with others!

- Manufacturers’ Resources: Check the websites of lathe makers for manuals and support.

What are some good online courses for learning about metal lathe wiring?

Online platforms like Udemy and Skillshare offer beginner courses. They teach basic wiring and lathe techniques in simple terms. Perfect for hands-on learners!

Conclusion

In conclusion, understanding a metal lathe wiring diagram is vital for safe and effective operation. It helps you connect wires properly and troubleshoot issues. You can improve your skills by studying these diagrams and practicing with your lathe. So, dive into further reading and hands-on projects to enhance your knowledge. Remember, safety comes first in any workshop!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Wiring Diagrams:Metal lathe wiring diagrams show how to connect wires in a metal lathe. They help you understand where each wire goes. If you follow the diagram, you can set up the lathe safely. Always make sure to check the diagram before starting. It helps you avoid mistakes and keep everything working properly.

Sure! Please let me know what question you would like me to answer.

What Are The Essential Components That Should Be Included In A Metal Lathe Wiring Diagram?A metal lathe wiring diagram needs some important parts. First, it should show the power supply, where the electricity comes from. Next, we need to include the motor, which makes the lathe spin. You should also mark the switches that turn the lathe on and off. Finally, show the connections between wires to keep everything safe.

How Do You Interpret The Wiring Connections For The Motor And Controls In A Metal Lathe Wiring Diagram?To read a wiring diagram for a metal lathe, you look for lines and symbols. Each line shows a wire connection. Control parts like switches and buttons are also shown. You match the colors of wires to see where they go. This helps us connect the motor and controls correctly.

What Safety Precautions Should Be Taken When Working With The Electrical Wiring Of A Metal Lathe?When working with the electrical wiring of a metal lathe, you should always turn off the power first. Make sure to wear rubber gloves to keep yourself safe. Check the wires for any damage or breaks before touching them. It’s also a good idea to keep your work area dry to avoid shocks. Finally, never work alone; always have someone nearby in case you need help.

How Can You Troubleshoot Common Electrical Issues Using A Metal Lathe Wiring Diagram?To troubleshoot common electrical problems with a metal lathe, start by looking closely at the wiring diagram. This diagram shows how all the wires are connected. If something isn’t working, check if any wires are loose or broken. You can also follow the diagram to see if power is going to all the right parts. If you’re stuck, ask someone for help!

Where Can You Find Manufacturer-Specific Wiring Diagrams For Different Models Of Metal Lathes?You can find specific wiring diagrams for metal lathes on the manufacturer’s website. Look for a section called “Support” or “Manuals.” You can also check online forums where people share info about lathes. Lastly, try asking in groups or clubs where people talk about metalworking.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe wiring diagrams show how to connect wires in a metal lathe. They help you understand where each wire goes. If you follow the diagram, you can set up the lathe safely. Always make sure to check the diagram before starting. It helps you avoid mistakes and keep everything working properly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please let me know what question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components That Should Be Included In A Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe wiring diagram needs some important parts. First, it should show the power supply, where the electricity comes from. Next, we need to include the motor, which makes the lathe spin. You should also mark the switches that turn the lathe on and off. Finally, show the connections between wires to keep everything safe.”}},{“@type”: “Question”,”name”: “How Do You Interpret The Wiring Connections For The Motor And Controls In A Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To read a wiring diagram for a metal lathe, you look for lines and symbols. Each line shows a wire connection. Control parts like switches and buttons are also shown. You match the colors of wires to see where they go. This helps us connect the motor and controls correctly.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Working With The Electrical Wiring Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working with the electrical wiring of a metal lathe, you should always turn off the power first. Make sure to wear rubber gloves to keep yourself safe. Check the wires for any damage or breaks before touching them. It’s also a good idea to keep your work area dry to avoid shocks. Finally, never work alone; always have someone nearby in case you need help.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Electrical Issues Using A Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot common electrical problems with a metal lathe, start by looking closely at the wiring diagram. This diagram shows how all the wires are connected. If something isn’t working, check if any wires are loose or broken. You can also follow the diagram to see if power is going to all the right parts. If you’re stuck, ask someone for help!”}},{“@type”: “Question”,”name”: “Where Can You Find Manufacturer-Specific Wiring Diagrams For Different Models Of Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find specific wiring diagrams for metal lathes on the manufacturer’s website. Look for a section called “Support” or “Manuals.” You can also check online forums where people share info about lathes. Lastly, try asking in groups or clubs where people talk about metalworking.”}}]}