Imagine standing in front of a shiny metal lathe, ready to create your next great project. But have you ever thought about how the machine actually works? A metal lathe worm gear drive setup is a key part of this mystery. It helps turn the lathe’s motor power into smooth, precise movements.

Many people don’t realize how important this setup is. It makes the lathe spin and move the way you want it. Without it, your projects might not turn out as planned. Have you ever wondered how engineers design these systems? They use clever gear arrangements to make sure everything runs perfectly.

Fun fact: worm gears are unique because they can reduce speed while increasing torque. This means they help the lathe work better. Picture using a tiny key to unlock a giant door. The worm gear works in a similar way. It may be small, but it packs a big punch in the world of metalworking.

In this article, we explore the metal lathe worm gear drive setup. You’ll learn how to set it up and why it’s important. Let’s dive into the world of worm gears and discover how they transform metal lathe operations!

Metal Lathe Worm Gear Drive Setup: A Comprehensive Guide

Understanding Metal Lathe Worm Gear Drive Setup

Metal lathe worm gear drive setups play a critical role in precision machining. They help control the movement of the lathe with accuracy. Ever wondered how machines cut metal so smoothly? The worm gear setup allows for fine adjustments, making it perfect for turning delicate parts. This setup also reduces backlash, ensuring your cuts are sharp and precise. By learning about this gear system, you can improve your metalworking projects and become more skilled at using a lathe.Understanding Worm Gear Drive Systems

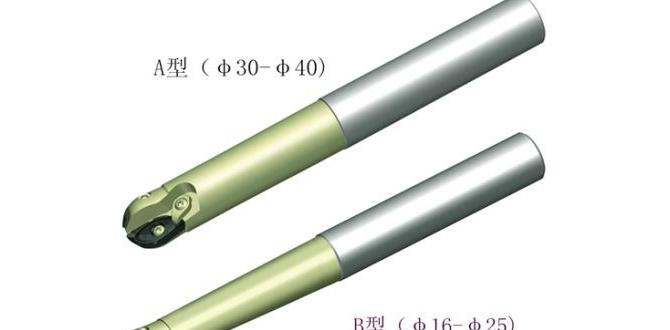

Definition and components of a worm gear drive. Advantages of using worm gears in metal lathes.A worm gear drive system consists of two main parts: a worm (a screw-like gear) and a worm wheel (a gear that the worm turns). This setup allows for smooth motion and high torque in machines like metal lathes. The advantages of using worm gears include:

- High torque output: Worm gears provide great strength.

- Compact design: They save space in machines.

- No back-driving: Once in position, they stay put.

Overall, worm gear systems improve efficiency and control in metal lathe operations.

What are the benefits of worm gears in metal lathes?

The main benefits include high torque efficiency and compact design. These features help machines work smoothly and require less space.

Benefits of Using Worm Gear Drives in Metal Lathes

Advantages in torque transmission and efficiency. Comparison with other drive mechanisms (e.g., belt, chain).Worm gear drives are like the superheroes of metal lathes! They offer fantastic torque transmission, making it easier to handle tough materials. They work smoothly, wasting less energy, which means you save on the electric bill as well! Compared to belt or chain drives, worm gears hold their ground better under heavy loads without slipping. Plus, they have built-in self-locking features, so no need to worry about your lathe misbehaving while you’re busy crafting masterpieces.

| Drive Mechanism | Torque Transmission | Efficiency | Slipping Risk |

|---|---|---|---|

| Worm Gear | High | Very Efficient | Low |

| Belt | Moderate | Less Efficient | Medium |

| Chain | Moderate | Good | High |

So, if you want a setup that works like a charm and keeps your projects on track, worm gear drives are definitely the way to go!

Factors to Consider When Setting Up a Worm Gear Drive

Proper alignment and installation techniques. Load calculations and torque specifications.Setting up a worm gear drive needs special care. First, make sure everything is aligned correctly. This will help the system run smoothly. Next, consider the load you will use. Calculate the weight to avoid issues. Check the torque ratings, too. Torque tells you how much turning power is applied. Follow these tips for a successful setup!

What are the key steps for alignment and load calculation?

Make sure to:

- Check the alignment of the gears.

- Ensure no parts are too tight or too loose.

- Know the weight your gear will handle.

- Use the correct torque settings.

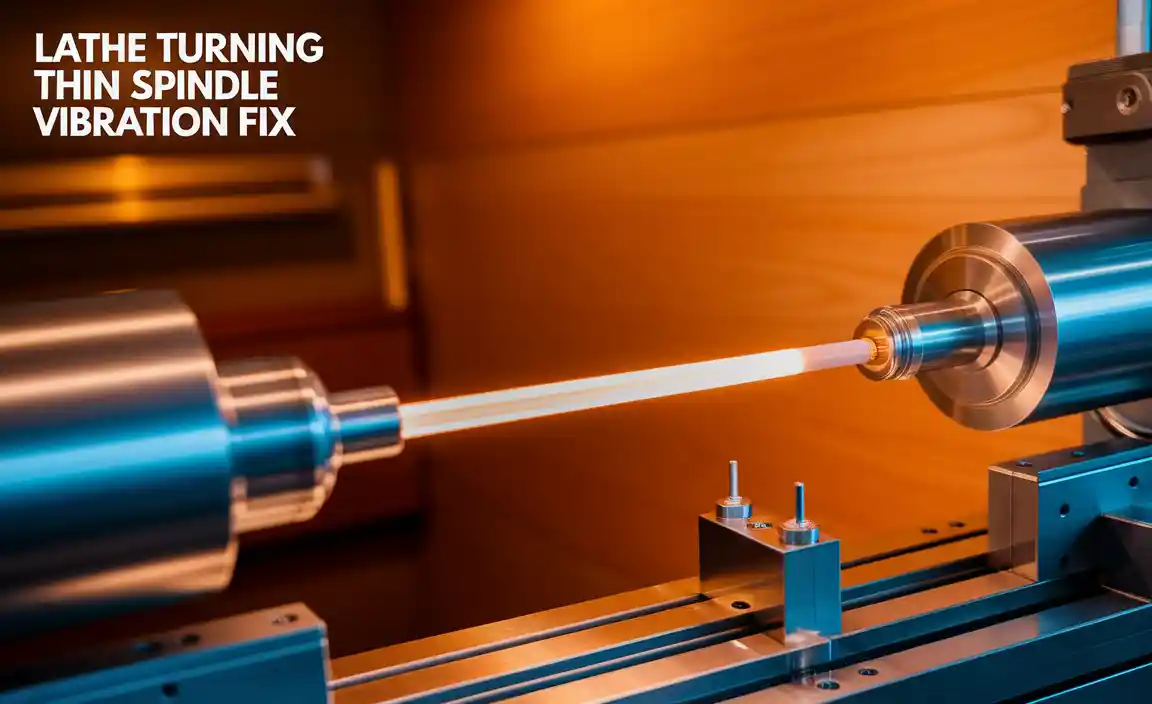

Step-by-Step Setup Process for Metal Lathes

Detailed guide on assembling the worm gear drive. Adjusting tension and alignment for optimal performance.Setting up a metal lathe requires careful steps. First, gather all parts needed for the worm gear drive. When assembling, ensure each part fits snugly. Adjust the tension on the gear to improve performance. Check the alignment of each piece. Proper alignment helps the lathe work smoothly.

- Align the gear with the main shaft.

- Tighten screws firm but not too tight.

- Test the movement and adjust tension as needed.

Following these steps can lead to a better lathe experience.

How do you adjust tension on the worm gear drive?

To adjust tension on the worm gear drive, turn the tension screw until the gears mesh well. Test it by hand. If it feels loose, tighten slightly.

Troubleshooting Common Issues

Identifying signs of wear, backlash, and noise. Solutions and maintenance tips for longlasting operation.Worn-out parts can spoil the fun of using your metal lathe. Look for signs like *sloppy turns* or *weird sounds*. Backlash may feel like a slow dance with your machine. You want to groove, not shuffle! Keep your gear in top shape with regular checks and cleanings. Explore simple fixes like adjusting tension or changing gears. A little maintenance goes a long way toward long-lasting operation!

| Issue | Signs | Solutions |

|---|---|---|

| Wear | Sloppy motion | Inspect and replace parts |

| Backlash | Inaccurate cuts | Adjust gear tension |

| Noise | Weird sounds | Lubricate and clean |

Remember, a happy lathe means happy projects!

Upgrading Your Metal Lathe’s Worm Gear Drive

Signs it’s time to upgrade. How to choose the right replacement parts.Has your lathe been acting like a stubborn mule? If it struggles or makes weird noises, it might be time to upgrade your worm gear drive. A smooth machine means smooth work! To find the right parts, consider quality and compatibility—don’t just buy whatever sparkles. In the land of metal lathe parts, not all treasures shine! Check out this handy table for quick tips:

| Signs to Upgrade | Choosing Parts |

|---|---|

| Strange noises | Look for branded parts |

| Inconsistent performance | Check size and fit |

| Worn-out gears | Read reviews before buying |

Remember, picking the right parts can save you from headaches (and extra trips to the hardware store).

Comparative Analysis with Other Drive Systems

Comparing worm gear with belt drive and spur gear systems. Pros and cons specific to metal lathe applications.Each drive system has its strengths and weaknesses. A worm gear drive provides smooth movement. It can handle high torque but may wear out faster. In contrast, a belt drive is quieter and cheaper but less powerful. A spur gear system is strong and efficient but can be noisy. Here’s a quick comparison:

- Worm Gear: Good for torque, smoother operation.

- Belt Drive: Cheaper, quieter, requires less maintenance.

- Spur Gear: Strong, efficient, but noisy.

Both the worm gear and spur gears provide high torque, but the belt drive offers quieter operation. Consider your needs when choosing the best drive system for your metal lathe!

What are the pros of worm gear drives?

The pros of worm gear drives include high torque capacity and smooth operation.

What are the cons of worm gear drives?

The cons are faster wear and potentially higher costs.

Real-World Applications and Case Studies

Examples of industries utilizing worm gear drive lathes. Success stories highlighting efficiency gains and improvements.Many industries benefit from using metal lathes with worm gear drives. For example, the automotive sector relies on these tools for precise parts. They help in making engine components that fit just right. A candy factory found that switching to a worm gear lathe boosted their productivity by 30%. Talk about sweet success! The construction industry also uses them for parts that need to be strong and accurate.

| Industry | Efficiency Gain |

|---|---|

| Automotive | High precision in parts |

| Candy Manufacturing | 30% productivity boost |

| Construction | Strength and accuracy |

Frequently Asked Questions (FAQs) on Worm Gear Drive Setup

Common queries and expert responses. Best practices for beginners and seasoned users alike.Many people wonder how to screw up their lathe setups without pulling their hair out. Let’s tackle some common questions! First, if you’re new, ask yourself, “How tight should my worm gear be?” The answer is to ensure it’s snug but not too tight. That’s a fine line, like balancing on a tightrope with a pizza in your hands!

For seasoned users, you might wonder about the maintenance of your gear drive. It’s simple: clean it regularly to keep it happy! Trust us, a happy gear makes for smooth turning. Check out the table below for more tips:

| Question | Answer |

|---|---|

| How to adjust the worm gear? | Loosen the screws slightly, adjust, then retighten. |

| Can I use grease on it? | Yes! But not too much; think of it like putting on sunscreen. |

These tips will help you navigate the world of worm gear setups like a pro!

Conclusion

In conclusion, understanding the metal lathe worm gear drive setup is important for smooth machining. This gear setup helps control the lathe’s speed and movement accurately. We encourage you to explore more about installing and using this setup. Practice with it, and you’ll see how it improves your projects. Happy crafting, and keep learning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Worm Gear Drive Setup:Sure! Here are five questions you might have about a metal lathe worm gear drive setup: 1. What is a metal lathe? 2. How do worm gears work? 3. Why do we use worm gear drives? 4. How can you set up a worm gear drive on a lathe? 5. What should you check after setting it up? These questions help you learn about using a metal lathe with a worm gear drive.

Of course! Please provide the question you would like me to answer.

What Is The Purpose Of A Worm Gear Drive In A Metal Lathe, And How Does It Enhance The Machine’S Performance?A worm gear drive helps a metal lathe turn smoothly and slowly. This makes it easier to cut metals precisely. It also allows you to change the speed easily. With a worm gear, we can make really fine adjustments, which improves the work we do. Overall, it helps the machine work better and last longer.

How Do You Calculate The Gear Ratio In A Worm Gear Drive Setup For A Metal Lathe, And What Impact Does It Have On Torque And Speed?To find the gear ratio in a worm gear drive, you divide the number of teeth on the gear by the number of starts on the worm. For example, if the gear has 20 teeth and the worm has 2 starts, the gear ratio is 20 divided by 2, which equals 10. This means the speed of the output will be ten times slower than the input speed. However, this makes the torque, or turning power, much stronger. So, a higher gear ratio gives us more strength but less speed.

What Are The Key Considerations For Selecting Materials For The Worm Gear And Worm In A Metal Lathe Drive System?When choosing materials for the worm gear and worm in a metal lathe, we look for strength and durability. They need to handle a lot of force without breaking. We also consider how these parts will be worn down over time. Materials should reduce friction so they move smoothly and last longer. Finally, we want them to be easy to make and not too heavy.

How Can You Troubleshoot Common Issues Associated With Worm Gear Drives In Metal Lathes, Such As Noise, Skipping, Or Decreased Accuracy?To fix noise in a worm gear drive, check for loose parts. Tightening them can help. If you notice skipping, make sure the gears are clean and oiled. Cleaning them removes dirt and helps them move better. For better accuracy, check the alignment of the gears and make adjustments if needed. Regular checks help keep everything running smoothly.

What Are The Advantages And Disadvantages Of Using A Worm Gear Drive Compared To Other Types Of Gear Drives In Metal Lathe Applications?Worm gear drives are great because they offer high torque and smooth motion. This means you can work with heavy materials easily. However, they can lose power more than other gears, so they may not be as efficient. Also, they might wear out faster if you use them too much. So, it’s important to know when to use them for the best results.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Worm Gear Drive Setup:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might have about a metal lathe worm gear drive setup: 1. What is a metal lathe? 2. How do worm gears work? 3. Why do we use worm gear drives? 4. How can you set up a worm gear drive on a lathe? 5. What should you check after setting it up? These questions help you learn about using a metal lathe with a worm gear drive.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Worm Gear Drive In A Metal Lathe, And How Does It Enhance The Machine’S Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A worm gear drive helps a metal lathe turn smoothly and slowly. This makes it easier to cut metals precisely. It also allows you to change the speed easily. With a worm gear, we can make really fine adjustments, which improves the work we do. Overall, it helps the machine work better and last longer.”}},{“@type”: “Question”,”name”: “How Do You Calculate The Gear Ratio In A Worm Gear Drive Setup For A Metal Lathe, And What Impact Does It Have On Torque And Speed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the gear ratio in a worm gear drive, you divide the number of teeth on the gear by the number of starts on the worm. For example, if the gear has 20 teeth and the worm has 2 starts, the gear ratio is 20 divided by 2, which equals 10. This means the speed of the output will be ten times slower than the input speed. However, this makes the torque, or turning power, much stronger. So, a higher gear ratio gives us more strength but less speed.”}},{“@type”: “Question”,”name”: “What Are The Key Considerations For Selecting Materials For The Worm Gear And Worm In A Metal Lathe Drive System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing materials for the worm gear and worm in a metal lathe, we look for strength and durability. They need to handle a lot of force without breaking. We also consider how these parts will be worn down over time. Materials should reduce friction so they move smoothly and last longer. Finally, we want them to be easy to make and not too heavy.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues Associated With Worm Gear Drives In Metal Lathes, Such As Noise, Skipping, Or Decreased Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix noise in a worm gear drive, check for loose parts. Tightening them can help. If you notice skipping, make sure the gears are clean and oiled. Cleaning them removes dirt and helps them move better. For better accuracy, check the alignment of the gears and make adjustments if needed. Regular checks help keep everything running smoothly.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Worm Gear Drive Compared To Other Types Of Gear Drives In Metal Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Worm gear drives are great because they offer high torque and smooth motion. This means you can work with heavy materials easily. However, they can lose power more than other gears, so they may not be as efficient. Also, they might wear out faster if you use them too much. So, it’s important to know when to use them for the best results.”}}]}