Have you ever wondered how tiny tools can make big changes in manufacturing? Micro milling tools hold the key. These small but powerful tools are essential in many industries. They help create parts that are precise and detailed.

Imagine building a small model of the Eiffel Tower. Each tiny piece needs to fit perfectly to look just right. That’s where micro milling tools come in. They cut materials with great accuracy, fitting parts together like a puzzle.

Did you know that micro milling tools are used in medicine and electronics? In healthcare, they help make tiny devices that save lives. In electronics, they create complex circuits that power our gadgets. The applications seem endless!

As you read further, you’ll discover how micro milling tools work and the many ways they are applied across different fields. Get ready to dive into the fascinating world of micro milling!

Micro Milling Tools Applications: Precision Engineering Solutions

Micro milling tools are used in many industries for precise cutting and shaping. They help make tiny parts for electronics, medical devices, and even jewelry. Imagine creating a tiny component smaller than a grain of rice! These tools ensure high accuracy, saving time and reducing waste. Curious about their role in making everyday gadgets? With micro milling, complex designs become easier to achieve, making innovation possible. Their versatility keeps industries moving forward.

Understanding Micro Milling Tools

Definition and characteristics of micro milling tools. Types of micro milling tools and their specific uses.

Micro milling tools are small cutting instruments used to remove material. They are perfect for making very precise parts. These tools are usually made from durable materials like carbide. They come in several types, each with a special use.

- End Mills: Great for cutting on the side and end.

- Drills: Used to create holes.

- Reamers: Perfect for smoothing holes.

- Ball Nose Cutters: Ideal for curved surfaces.

These tools help create tiny, detailed pieces for electronics, medical devices, and models. Their ability to work on small areas makes them very useful in many industries.

What are micro milling tools used for?

Micro milling tools are used in industries like electronics, aerospace, and medical device manufacturing. They create small, precise parts that other tools can’t.

Applications in Aerospace Industry

Precision machining requirements for aerospace components. Benefits of using micro milling tools in aerospace applications.

In the aerospace industry, precision is a must! Micro milling tools help create parts that fit together like puzzle pieces. They can make tiny, accurate cuts that are essential for aircraft engines and other components. Using these tools can lead to lighter, stronger parts, making flights safer and more efficient. Plus, less material waste means more money saved—like finding money in your coat pocket! Who knew precision could be so fun?

| Application | Benefit |

|---|---|

| Aerospace Components | High precision machining |

| Engine Parts | Increased strength |

| Fuel Systems | Reduced weight |

Micro Milling in Medical Device Manufacturing

Importance of precision in medical device production. Case studies of micro milling tool usage in medical sector.

Precision is key in making medical devices. A tiny mistake can lead to big problems! Micro milling tools help create perfect parts. They ensure that every measurement is spot on. For example, in heart stents, these tools shape tiny tubes with extreme accuracy. This means fewer chances of failure and better patient safety.

| Application | Description |

|---|---|

| Heart Stents | Thin tubes for blood flow, requiring precise measurements. |

| Surgical Implants | Custom-fit parts for surgeries, needing flawless design. |

Using micro milling tools in medicine isn’t just smart; it’s life-saving! So next time you hear “micro milling,” remember it might save someone’s day—or even their life!

Electronics and Micro Milling Technology

Role of micro milling tools in PCB and microelectronic applications. Advancements in micro milling for miniaturized components.

Micro milling tools play a big role in electronics, especially in creating printed circuit boards (PCBs) and tiny microelectronic parts. These tools help make small cuts and shapes accurately, which is key for today’s miniaturized devices. Recent advancements allow manufacturers to produce smaller, more efficient components. This helps tech gadgets work better and last longer.

- Precise shaping of PCBs

- Creation of intricate microelectronic designs

- Increasing efficiency of small devices

What is the importance of micro milling tools in electronics?

Micro milling tools help create incredibly small and detailed parts for electronics. This allows devices to be lighter, faster, and more powerful.

Automotive Industry Applications

Use of micro milling tools in manufacturing engine components. Examples of efficiency and design enhancements through micro milling.

Micro milling tools play a big role in making car parts. They help create engine components with incredible precision. For example, a tiny tool can shape block components in ways a big machine can’t. This means parts fit better and work faster. Efficiency skyrockets! Did you know using micro milling can save up to 30% on material waste? That’s like finding extra fries at the bottom of the bag—yummy and surprising!

| Part | Benefits |

|---|---|

| Engine Blocks | Improved fit and reduced weight |

| Pistons | Enhanced performance and responsiveness |

| Fuel Injectors | Higher efficiency and less fuel wastage |

These tiny tools bring big changes. They make cars lighter and faster. So next time you drive, remember how micro milling helps your engine roar!

Advantages of Micro Milling Techniques

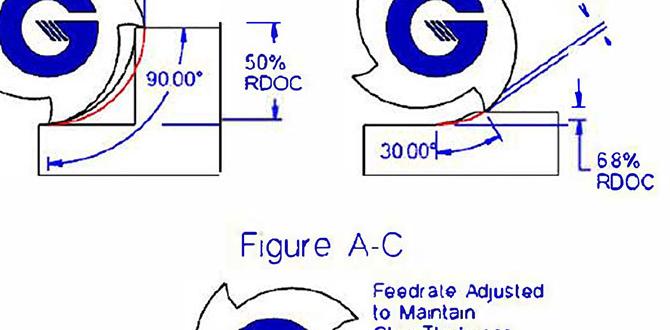

Comparison with traditional milling methods. Costeffectiveness and operational efficiency.

Micro milling techniques offer many benefits compared to traditional milling. They are cost-effective because they use less material and energy. This can save businesses money. They are also more precise, allowing for detailed work, which reduces waste. Micro milling can boost operational efficiency. It speeds up production and lowers overhead costs.

- Less wear and tear on tools

- Improves production speed

- Lower energy needs

How do micro milling techniques compare to traditional milling?

Micro milling is usually faster and more precise than traditional methods. It allows for finer details and less wasted materials, making it a better choice for many projects.

In conclusion, using micro milling techniques can lead to better results and lower costs. This helps businesses stay competitive in their markets.

Challenges and Considerations in Micro Milling

Common issues faced in micro milling processes. Solutions and technologies to overcome challenges.

Micro milling can be tough. Tools can wear out quickly. Most machines have high vibration levels, which leads to mistakes. Parts can break. Also, getting the right size and shape isn’t easy. But there are ways to fix these problems:

- Improve tool design for less wear.

- Use better machines with reduced vibration.

- Monitor processes with smart technology.

- Train workers to handle tools correctly.

Finding solutions can help workers make better products. They can keep machines running smoothly. This will help in making micro milling safer and more efficient.

What are the common issues in micro milling?

Common issues include tool wear, vibration, and achieving precise sizes.

Solutions to improve micro milling:

- Use high-quality materials.

- Invest in advanced machinery.

- Implement regular training for operators.

Future Trends in Micro Milling Applications

Innovations shaping the future of micro milling tools. Emerging sectors adopting micro milling technology.

Exciting changes are coming for micro milling tools. New inventions help them work faster and more precisely. Industries like medical devices and electronics are jumping on board, using micro milling to create tiny parts. This trend means things can get even smaller and more complex! Imagine a tiny robot making parts like a pro chef with the sharpest knife. The future looks bright, and yes, maybe even a little bit wacky!

| Emerging Sectors | Micro Milling Benefits |

|---|---|

| Medical Devices | High precision, small parts |

| Electronics | Complex designs, miniaturization |

| Aerospace | Weight reduction, enhanced performance |

Conclusion

In summary, micro milling tools help create precise parts in many industries, from electronics to healthcare. They enable us to make smaller, more detailed products efficiently. If you’re curious about how these tools work or their applications, consider exploring more resources. Understanding micro milling can inspire your creativity and perhaps guide your future projects!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Micro Milling Tools Applications:

Micro milling tools are tiny tools used to cut and shape materials like metal and plastic. You can use them to make small parts for machines or toys. They help create detailed designs, like patterns or letters. These tools can also help repair small items. That’s why they are important for engineering and crafting!

Sure! Just give me the question you want me to answer, and I’ll help you with it.

What Industries Benefit The Most From The Use Of Micro Milling Tools, And How Do They Enhance Production Efficiency?

Micro milling tools help a lot in industries like aerospace, medical, and electronics. They make very small and precise parts. This means they can create items faster and with fewer mistakes. When things are made better, companies save time and money. Using these tools helps everyone work more efficiently!

What Are The Key Differences In Design And Functionality Between Traditional Milling Tools And Micro Milling Tools?

Traditional milling tools are bigger and used for cutting large materials. They work on things like metal and wood. Micro milling tools are much smaller and make tiny, precise cuts. You can use them for detailed work, like creating tiny shapes or patterns. The designs of these tools help them do very different jobs.

How Do Micro Milling Tools Contribute To Precision Manufacturing In The Production Of Medical Devices And Components?

Micro milling tools help make very tiny and detailed parts for medical devices. They can carve out shapes that are really small, which is important for things like heart monitors or tiny robots used in surgeries. When we use these tools, we get better and more accurate parts. This means the devices work better and keep people safe. Overall, micro milling tools make sure that every little piece fits perfectly!

What Materials Are Most Commonly Machined Using Micro Milling Techniques, And What Challenges Are Associated With These Materials?

Micro milling is often used to cut materials like metal, plastic, and wood. These materials are popular because they can be shaped into tiny, precise parts. However, working with them can be tricky. For example, thin parts can break easily, and small tools can wear out quickly. We need to be careful to get good results!

How Can Advancements In Micro Milling Technology Improve The Capabilities Of Additive Manufacturing Processes?

Advancements in micro milling technology can help additive manufacturing, which makes things layer by layer. When we use micro milling, we can create very tiny and detailed parts. This means we can make stronger and more precise objects. It also helps to combine different materials better. Overall, these improvements make our creations better and more useful!