Have you ever watched a machine cut through metal? It’s fascinating to see how it shapes the material. One important tool in this process is the milling cutter. But do you know about the concept of axial chip thinning?

This idea is all about how the shape of the cutter and the way it moves affects the chips it creates. Imagine slicing through a cake. If you slice quickly, the pieces can be thinner and easier to handle. The same thing happens in milling! The speed and angle make a big difference.

Axial chip thinning plays a huge role in making cuts smoother and more efficient. It not only saves time but also helps keep your tools from wearing out too fast. Pretty neat, right?

In this article, we’ll explore what axial chip thinning means. We’ll discover why it matters in milling and how it can help machinists do their jobs better. So, grab your tools and let’s dive into the exciting world of milling cutters!

Understanding The Milling Cutter Axial Chip Thinning Concept

Milling Cutter Axial Chip Thinning Concept

When using a milling cutter, understanding the axial chip thinning concept is essential. This principle shows how the cutting thickness decreases as the cutter moves along the workpiece. Think of it like slicing a loaf of bread; the blade cuts thinner slices at an angle. By applying this idea, manufacturers can improve cutting efficiency and extend tool life. Did you know that proper chip thinning can reduce energy usage too? It’s a clever way to make machining easier and more effective!Understanding Axial Chip Thinning

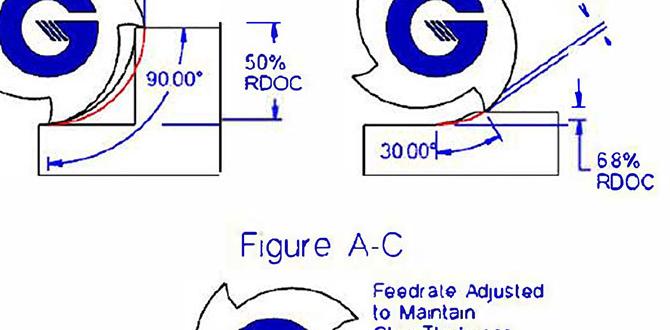

Definition and importance in milling processes. Comparison with radial chip thinning.Axial chip thinning is a special trick in milling where chips become thinner as they move along the cutter. This is super important because it helps improve efficiency and cuts better. Think of it like making pancakes—if you use a flat pan, the pancakes spread and cook evenly. In contrast, radial chip thinning is like cooking a muffin in a deep cup—thicker on the sides and lighter in the center. Each method has its own role, but axial chip thinning is often favored for better surface finishes!

| Aspect | Axial Chip Thinning | Radial Chip Thinning |

|---|---|---|

| Chip Thickness | Thinner along the cutter | Varies with radius |

| Efficiency | Higher due to better removal | Lower, can lead to excess heat |

| Surface Finish | Improved quality | May vary |

Effects of Axial Chip Thinning on Tool Performance

Impact on tool life and wear rates. Influences on surface finish and dimensional accuracy.Axial chip thinning affects how tools perform in many ways. It can help or hurt the tool’s life. With less material taken away, tools may last longer, reducing wear rates. However, if done poorly, tools wear quickly. This can lead to:

- Rough Surface Finish: It can create bumps and uneven surfaces during cutting.

- Dimensional Accuracy Problems: Parts might not fit properly if measurements are off.

Using proper techniques can improve tool life and make better parts.

How does axial chip thinning affect tool performance?

Axial chip thinning improves tool life by reducing wear rates but can harm surface finish and accuracy if not managed well.

Calculating Axial Chip Thinning

Formulae to determine chip thickness. Factors affecting chip thickness during milling.To find chip thickness in milling, you can use the formula: h = t / cos(α), where h is chip thickness, t is the depth of cut, and α is the angle of the cutting edge. Factors that affect chip thickness include:

- Cutting speed

- Feed rate

- Tool geometry

- Material properties

Understanding these elements helps in predicting how thick the chips will be during cutting, making milling more efficient.

What affects the thickness of chips during milling?

Many factors can change chip thickness. Tool shape, feed rate, and cutting speed all play crucial roles. For instance, if the feed rate is fast, chips may become thicker.

Strategies to Optimize Axial Chip Thinning

Adjusting cutting parameters (feed rate, depth of cut). Tool selection and machining strategies.To improve axial chip thinning, adjust your cutting parameters. Use a higher feed rate and reduce the depth of cut. This can lead to better results. Choose the right tool for your job. Each tool has different features that can impact performance. Combine these strategies for the best machining outcomes.

- Increase feed rate for faster cutting.

- Decrease depth of cut for thinner chips.

- Select the right tool for specific materials.

How Do You Optimize Cutting Parameters?

Balance the feed rate and depth of cut. Too high a feed rate may reduce finish quality. Finding the sweet spot can truly enhance your machining experience.

Applications of Axial Chip Thinning in Various Industries

Use in automotive and aerospace manufacturing. Benefits for complex geometries and highspeed machining.Many industries, such as automotive and aerospace, use axial chip thinning. This technique improves production. It helps create complex shapes while speeding up machining. Manufacturers can achieve better precision without sacrificing time. Benefits include:

- Faster processing speeds

- Reduced tool wear

- Higher surface quality

Using axial chip thinning means fewer mistakes and better results in these demanding fields.

Why is axial chip thinning important in manufacturing?

It allows for quicker production and better quality, making complex designs easier to achieve.

Common Challenges and Solutions in Axial Chip Thinning

Identifying and mitigating issues related to chip formation. Solutions for improving machining efficiency.Many people face problems when making chips with milling cutters. These challenges can slow down production. Identifying chip formation issues is key. Solutions can improve efficiency and make work easier. Here are some ways to tackle these problems:

- Maintain proper tool angles.

- Use the right cutting speed.

- Adjust feed rates carefully.

- Choose suitable materials.

By fixing chip issues, you can speed up machining and save resources. This makes for smoother operations and happier workers.

How can chip formation issues be identified?

Chip formation issues can be spotted by looking at the size and shape of the chips. If chips are too big or wrong-shaped, it signals a problem.

Future Trends in Milling Cutter Technology

Innovations in tool materials and coatings. Advancements in CNC technology related to axial chip thinning.New tools are changing how we work with milling cutters. Innovations in materials make them last longer and cut better. Stronger coatings help resist wear and tear. These improvements mean lower costs and better results. In CNC technology, axial chip thinning helps machines run smoother and faster, making production quicker and more efficient. This means less waste and better pieces.

What are the benefits of new milling cutter technologies?

New milling cutter technologies offer longer tool life and improved cutting precision. They can also reduce the time needed to create parts, making manufacturing quicker and more efficient.

Key Benefits:

- Longer lifespan of tools

- Better cutting performance

- Less waste during production

Conclusion

In conclusion, the axial chip thinning concept helps us understand how a milling cutter removes material effectively. This technique allows for faster cutting and better finishes. By using this knowledge, you can improve your machining projects. Practice applying these ideas in your work, and consider exploring more about milling processes to enhance your skills even further!FAQs

Sure! Here Are Five Questions Related To The Concept Of Axial Chip Thinning In Milling Cutters:Axial chip thinning is when a milling cutter removes less material than expected. This happens because of the angle we use when we cut. If we hold the cutter straight up and down, it cuts thinner slices. This means we can cut faster and save some power. It helps us make better shapes without wasting too much material.

Sure! I’ll do my best to keep it simple and clear. Please go ahead and ask your question.

What Is Axial Chip Thinning, And How Does It Affect The Thickness Of Chips Produced During Milling Operations?Axial chip thinning happens when we cut metal in a special way during milling. Imagine a pizza cutter slicing through dough at an angle. This angle makes the chips, or small pieces of metal, thinner than usual. When we change how we cut, we get less waste and better shapes. So, axial chip thinning helps us make smoother and more accurate products!

How Does The Geometry Of A Milling Cutter Influence Axial Chip Thinning In Machining Processes?The shape of a milling cutter affects how thin the chips become when we cut metal. If the cutter has a sharp angle, it can push the metal aside more easily, making thinner chips. This helps make a smoother surface. When we use a cutter with the right shape, we can cut faster and waste less material. So, the design really matters for how well we can cut things.

In What Ways Can Axial Chip Thinning Improve The Efficiency And Surface Finish Of Machined Components?Axial chip thinning helps make better cuts when we shape metal. When we cut more smoothly, we remove less material, which saves time and energy. This leads to fewer rough spots on the surface, making it look nicer. We also use less power, which can save money. Overall, it makes our work faster and our pieces cleaner!

What Are The Key Factors To Consider When Optimizing Cutting Parameters To Minimize The Effects Of Axial Chip Thinning?To reduce axial chip thinning, you should think about the cutting speed, feed rate, and depth of cut. Cutting speed is how fast you move the tool. The feed rate is how much material you remove with each pass. A smaller depth of cut can help too. Adjusting these three things can make cutting better and keep chips from getting too thin.

How Can Manufacturers Compensate For The Effects Of Axial Chip Thinning To Enhance Tool Life And Material Removal Rates?Manufacturers can reduce axial chip thinning by changing how the machine works. They can use sharper tools that cut better. You can also adjust the speed and direction of the machine to create better chips. By doing this, we help the tools last longer and remove more material quickly. This way, everyone benefits!