Have you ever wondered how we can measure the pressure when cutting metal? The answer lies in the milling cutter axial force measurement. This method helps engineers understand the forces at play when using milling cutters.

Think about when you’re cutting a piece of wood. You feel the resistance, right? Imagine the precision needed in a factory to ensure everything works smoothly. Measuring axial force makes that possible.

Here’s a fun fact: the right measurement can improve tool life and surface finish. This means better products and less waste! Everyone benefits from smart engineering.

In this article, we will dive into the world of milling cutter axial force measurement. We’ll explore why it matters and how it affects the manufacturing process. Prepare to discover the secrets behind this crucial aspect of machining!

Milling Cutter Axial Force Measurement: Key Techniques Explained

Milling Cutter Axial Force Measurement

Understanding milling cutter axial force measurement is crucial for precise machining. This technique helps track the forces acting on a cutting tool. Monitoring these forces can lead to better tool life and improved surface quality. Have you ever wondered why your tools wear out quickly? It’s often due to unmeasured forces. By measuring the axial force, operators can detect issues early and enhance productivity. This simple step can save time and money in manufacturing.Understanding Axial Force in Milling Operations

Definition and significance of axial force in milling processes. Factors influencing axial force during milling.Axial force measures how much force goes straight along the cutting tool during milling. This force is important because it affects how well a cutting tool works. If the axial force is too high or too low, it can cause problems like tool wear or bad cuts. The axial force can change due to several factors:

- The type of material being cut

- The cutting speed used

- The tool geometry

- The depth of cut

Understanding these factors helps improve milling processes and keeps tools in good shape.

What is the role of axial force in milling?

Axial force helps shape the material being cut and impacts tool life. It is key for smooth operations and helps achieve the desired results in milling tasks.

Instrumentation and Setup for Accurate Measurements

Required equipment for measuring axial force accurately. Best practices for setting up measurement systems in milling operations.Getting accurate measurements for your milling cutter’s axial force is like trying to catch a sneeze in the wind—challenging but doable! First, you’ll need some essential gear. Use a load cell fitted on the machine. It’s the superhero of measurement tools! Plus, don’t forget to calibrate it regularly for superhero-level accuracy.

| Required Equipment | Purpose |

|---|---|

| Load Cell | Measures axial force |

| Data Logger | Records force data |

| Calibrating Weights | Ensures accuracy |

Setting up your measurement system is also key. Position the load cell where it can receive the most force. This way, it’s like giving your measuring tools a front-row seat to the action. Remember, a steady setup means less chance for errors. Happy measuring!

Data Analysis in Axial Force Measurement

Methods for analyzing measurement data. Tools and software for effective data interpretation.Analyzing data from axial force measurement involves several methods. You can use basic tools like spreadsheets for simple calculations. For more complex analysis, software like MATLAB can help analyze trends. Other specialized tools provide visual data through charts. This makes understanding measurements easier. Here are some effective tools:

- Spreadsheets (Excel, Google Sheets)

- Data analysis software (MATLAB, Python)

- Visualization tools (Tableau, Power BI)

Using these tools helps in making sense of measurement data quickly. You can find patterns and improve milling cutter efficiency.

How to analyze measurement data effectively?

To analyze measurement data effectively, use software that allows for both statistical calculations and data visualization. Look for tools that fit your needs and simplify complex information. Always ensure your data is accurate before drawing conclusions.

Case Studies: Real-World Applications of Axial Force Measurement

Examples of axial force measurement in different industries (automotive, aerospace). Impact of measurements on process optimization and tool life.In many industries, measuring axial force helps make tools work better. In the automotive field, companies use this measurement to improve machine performance and save time. In aerospace, it helps make parts stronger and last longer. Here are some key benefits:

- Boosts tool life by reducing wear.

- Improves accuracy in cutting processes.

- Decreases production costs over time.

These measurements lead to safer, more reliable products. They ensure that industries can create high-quality machines while being efficient.

Why is measuring axial force important?

Measuring axial force is crucial because it enhances tool efficiency and lifespan. This leads to better product quality and cost savings.

Challenges and Limitations in Measuring Axial Force

Common obstacles faced during axial force measurement. Potential solutions to enhance measurement accuracy and reliability.Measuring axial force can feel like playing a game of hide and seek—sometimes, it hides right when you think you found it! A common challenge is dealing with vibrations from machines, which can throw off your readings. Another tricky part is ensuring the sensors are installed correctly because even a tiny misalignment can mess everything up. Don’t worry too much, though. Using better sensors and regular checks can help keep those readings accurate. A solid team of technicians can make all the difference!

| Challenges | Potential Solutions |

|---|---|

| Vibrations | Use dampening mounts |

| Sensor misalignment | Regular calibration checks |

| Temperature variations | Stable environment |

The Future of Milling Cutter Axial Force Measurement

Innovations and emerging technologies in measurement techniques. Predictions for advancements in milling cutter design and performance analysis.The world of milling cutter axial force measurement is changing fast! New tools and gadgets are popping up, making it easier to measure forces accurately. Innovations like smart sensors and AI are leading the way. These technologies promise improved performance and efficiency in designs. Predicting the future, we might see cutting tools that can talk to us—imagine your cutter saying, “I need a break!” Check out the table below for a quick glimpse of upcoming trends!

| Innovation | Description |

|---|---|

| Smart Sensors | Measure forces in real-time! |

| AI Integration | Analyze performance like a pro! |

| Adaptive Designs | Tools that adjust to conditions! |

Conclusion

In summary, measuring axial force in milling cutters helps us understand how tools perform. By tracking these forces, you can improve precision and tool life. We encourage you to explore more about this topic and consider how it can benefit your projects. Start measuring today and see the difference in your work!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Axial Force Measurement:Milling cutter axial force measurement helps us understand how hard the cutter pushes down while working. We can use special tools to measure this force. It’s important to check this force to make sure our machines work well. When we know the force, we can make better parts and keep everything safe. Always remember that measuring helps us improve our work!

Sure! Please provide me with the question you would like me to answer.

What Methods Are Commonly Used To Measure The Axial Force Exerted By A Milling Cutter During Machining Operations?To measure the force a milling cutter pushes down, we can use several methods. One way is to use a special tool called a dynamometer. This tool tells us how much force is acting on the cutter. Another method is to use strain gauges, which are tiny devices that measure small changes when force is applied. We can also use pressure sensors that detect the force by measuring air pressure changes.

How Does Axial Force Impact The Overall Performance And Lifespan Of Milling Cutters In Cnc Machining Processes?Axial force is the pressure that pushes the cutting tool straight down when we use it. Too much pressure can wear out the cutter quickly, making it dull. If the cutter is dull, it won’t cut as well, and we’ll have to replace it sooner. Keeping the right amount of axial force helps the cutter last longer and work better. So, we need to find a good balance for best results.

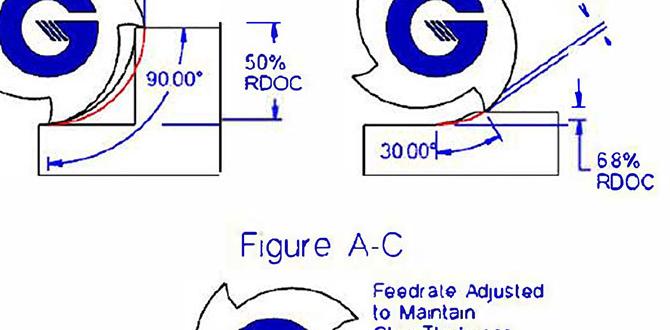

What Role Does Tooling Geometry Play In Influencing The Axial Force During Milling Operations?Tooling geometry is how a cutter is shaped. It affects how the cutter grips the material. If the angle is sharp, it cuts easier and needs less force. If it’s dull or flat, it needs more force to cut. So, better shapes help us cut better and use less energy.

Can Axial Force Measurement Help In Predicting And Preventing Tool Wear Or Failure During Machining? If So, How?Yes, measuring axial force can help us predict and stop tool wear or failure while machining. When we monitor the force, we can see if the tool is working too hard. If the force gets too high, we know the tool might break soon. By checking the force regularly, we can change the tool or adjust our work to keep everything safe and working well.

What Technological Advancements Have Been Made In Sensors Or Systems Designed For Accurate Axial Force Measurement In Milling Applications?New sensors help us measure forces better when we cut metal or wood. They use tiny lasers and special technology to give very precise readings. We can now see the force on a screen in real time. This helps us make better cuts and keeps machines safe. These upgrades make milling faster and more accurate!