Have you ever watched a machine cut shapes out of metal? It’s amazing how precise they can be. One essential tool in these machines is the milling cutter. But did you know that some milling cutters have special edge configurations?

These cutting edges come in different shapes and styles. Bimetal edge configurations are some of the most interesting. They combine two types of metal to make the cutter stronger and last longer. Imagine having a tool that can do the work of two!

But what does having a bimetal edge really mean for you? It can lead to better finishes and quicker production times. This article will explore the world of milling cutter bimetal edge configurations. We will dive into how they work and why they are so useful in today’s industry. Are you ready to learn something new?

Milling Cutter Bimetal Edge Configurations Explained

Milling Cutter Bimetal Edge Configurations

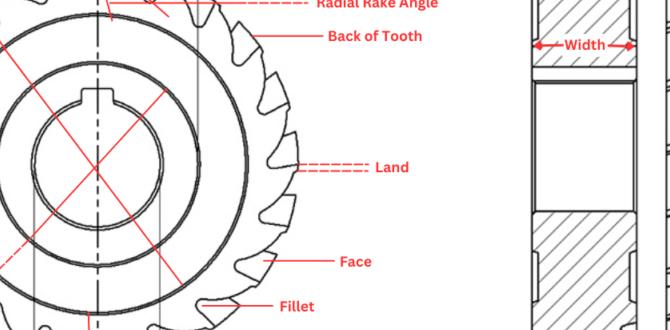

Milling cutter bimetal edge configurations are tools designed for precision. They combine two different metals to achieve a sharp and strong cutting edge. This technology helps cut through tough materials effectively. Have you ever wondered how a simple tool can create complex shapes in metal? These unique edges enhance durability and performance in milling tasks. The right configuration can make all the difference in your project’s outcome. Curious about finding the best cutter for your needs?Understanding Bimetal Edge Configurations

Definition of bimetal edge configurations. Importance of bimetal materials in milling cutters.Bimetal edge configurations are like the superhero of milling cutters, combining two strong materials into one marvelous tool. This means better performance when cutting. Using bimetal materials boosts durability, helping clips last longer and work better without breaking a sweat. Imagine trying to cut cheese with a butter knife—it’s a struggle! But with the right tools, everything gets easier. Bimetal solutions mean reduced wear and tear, leading to a longer cutter life. Let’s break it down:

| Aspect | Description |

|---|---|

| Definition | Combining two metals for strength and performance. |

| Importance | Enhances durability, cuts better, and lasts longer! |

Benefits of Bimetal Edge in Milling Cutters

Enhanced durability and wear resistance. Improved cutting performance and precision.The bimetal edge of milling cutters packs a punch in durability and wear resistance. This means they can tackle more tough jobs without wearing out. Imagine a superhero with a shield! Alongside this, these cutters boost cutting performance and precision. You get cleaner cuts and smoother finishes every time. It’s like having a magic wand that makes your work easier! In the table below, check out the key benefits:

| Benefit | Description |

|---|---|

| Enhanced Durability | Lasts longer, reducing the need for replacements. |

| Wear Resistance | Handles tough materials better without damage. |

| Improved Performance | Delivers clean cuts and increases efficiency. |

| Precision | Offers exact measurements for better results. |

Types of Bimetal Edge Configurations

Description of various edge configurations. Applications of different types in milling processes.Bimetal edge configurations come in various types. Each type serves a different purpose in milling. Here are some of the main kinds:

- Flat Edge: Ideal for smooth cutting.

- Curved Edge: Great for rounded shapes.

- Chamfered Edge: Helps in corner cutting.

These edges help tools work better in milling processes. For instance, a curved edge might be best for intricate designs. The right edge can make a big difference!

What are the applications of different edge types?

Each edge has its own use: flat edges work well in basic cutting, while curved edges fit complex shapes. Choosing the right edge is important for good results!

Factors Influencing Edge Configuration Selection

Material compatibility and machining requirements. Consideration of cutting speed and feed rate.Choosing the right edge configuration matters a lot. First, think about material compatibility. The cutter must work well with the material you’re machining. Different materials require different approaches. Next, keep machining requirements in mind. This affects how the cutter will perform. You also need to consider cutting speed and feed rate. The right settings lead to better cuts and longer tool life.

What are the main factors for selecting edge configurations?

The key factors are material compatibility, machining requirements, cutting speed, and feed rate. All these elements help in making sure that the cutter does its job well.

Comparative Analysis with Traditional Milling Cutters

Performance differences between bimetal and traditional cutters. Costeffectiveness of using bimetal edge configurations.Many folks want the best for their cutting tasks. Bimetal edge configurations stand out against traditional milling cutters. They last longer and work better, slicing through tough materials like butter. This means fewer breaks and more creations!

In terms of cost, bimetal cutters may have a higher upfront price but save you money in the long run. Imagine less downtime! That’s a win-win. For those still confused, here’s a little side-by-side:

| Feature | Traditional Cutters | Bimetal Edge Cutters |

|---|---|---|

| Durability | Less | More |

| Cost | Lower | Higher upfront, but cheaper over time |

| Performance | Good | Excellent |

In short, bimetal edge configurations offer better value and performance. Now that’s something you can cut a cake with!

Future Trends in Bimetal Milling Cutter Technology

Innovations in materials and design. Predictions for industry advancements and applications.Exciting changes are on the horizon for bimetal milling cutters! New materials are being developed, making cutters last longer and cut faster. Designs are getting sleeker, and you might soon see your favorite cutter sporting a high-tech look that even robots would envy! Industry insiders predict these advancements will boost productivity in factories worldwide. Think of it as a superhero upgrade for machines. It’s like giving your favorite toy a shiny new paint job, but this time it can slice through metal effortlessly!

| Trend | Description |

|---|---|

| Innovative Materials | Stronger alloys that last longer. |

| Sleek Designs | More efficient shapes for better cuts. |

| Increased Applications | Use in diverse industries, from car parts to toys! |

Case Studies: Successful Applications of Bimetal Milling Cutters

Review of industries using bimetal edge configurations. Analyzing performance metrics and outcomes.Bimetal milling cutters have shown amazing results across various industries. These cutters are used in construction, aerospace, and automotive fields. They help create stronger and more precise parts. Performance metrics indicate that bimetal edge configurations improve cutting speed while reducing wear. This saves money over time. Here are some important outcomes:

- Faster production rates.

- Less downtime for tool changes.

- Higher quality of finished products.

How do bimetal milling cutters improve factory productivity?

Bimetal milling cutters allow factories to work faster and more efficiently. They last longer and cut better, which helps producers make more items in less time.

Maintenance and Care for Bimetal Edge Milling Cutters

Best practices for prolonging cutter life. Signs of wear and when to replace the cutter.Taking care of bimetal edge milling cutters can make them last longer, just like how eating veggies helps you grow tall! First, keep your cutters clean. Dust and chips make them dull. Check for signs of wear, such as chips or cracks. If they’re looking like a sad cookie, it might be time for a replacement. Replacing them can save you from a big mess later on!

| Signs of Wear | Action to Take |

|---|---|

| Chips or cracks | Replace the cutter |

| Dull cutting | Sharpen or replace |

Following these simple tips keeps your tools happy, and they’ll work better for you. A happy cutter is a hardworking cutter!

Conclusion

In summary, milling cutter bimetal edge configurations combine toughness and durability. These tools help you cut materials efficiently. Understanding how they work can improve your projects. We encourage you to explore different types and find what suits your needs best. Keep learning about milling and its applications for better results in your work. Happy cutting!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Bimetal Edge Configurations:Sure! Here are some questions about milling cutter bimetal edge configurations: 1. What is a milling cutter? A milling cutter is a tool used to shape or cut materials like metal or wood. 2. Why do we use bimetal edges? Bimetal edges are strong and last longer. They help cut better and stay sharp. 3. How do you care for bimetal edges? You should clean them regularly and store them safely to prevent damage. 4. Can you use bimetal edges for different materials? Yes, bimetal edges can cut various materials, like hard metals and softer woods. 5. What makes bimetal edges special? They combine two types of metal, giving them more strength and better cutting ability.

Sure! Please share the question you would like me to answer.

What Are The Advantages Of Using Bimetal Edge Configurations In Milling Cutters Compared To Traditional Single-Material Designs?Bimetal edge configurations use two different materials. This makes them stronger and helps them last longer. They can cut better and stay sharp, so you don’t have to change them often. Also, they can handle more heat, which means they won’t break as easily. Overall, they work better than traditional single-material designs.

How Do The Different Edge Geometries In Bimetal Milling Cutters Affect Cutting Performance And Tool Life?Different edge shapes on bimetal milling cutters help them cut material in various ways. If the edge is sharp, it can cut faster but might wear out quickly. A thicker edge may last longer but might cut slower. So, finding the right edge shape helps tools work better and last longer. This way, you can finish your work more easily and save money on tools.

What Materials Are Typically Used In The Production Of Bimetal Edges For Milling Cutters, And How Do Their Properties Influence Cutting Efficiency?Bimetal edges for milling cutters are usually made of two different metals, like steel and carbide. Steel is strong and flexible, while carbide is very hard and stays sharp longer. These properties help the cutter cut materials easily and quickly. When we use the right bimetal, it makes cutting smoother and faster.

How Does The Manufacturing Process Of Bimetal Edge Milling Cutters Differ From That Of Conventional Milling Cutters?Bimetal edge milling cutters are made using two different metals. First, we create the cutting edge from a strong metal. Then, we attach this edge to a softer metal body. This makes the cutter tough and helps it last longer. Conventional milling cutters are usually made from one solid piece of metal, which can wear out faster.

What Are The Common Applications And Industries That Benefit From The Use Of Bimetal Edge Milling Cutter Configurations?Bimetal edge milling cutters are tools that help us cut and shape materials. We use them in many industries like cars and airplanes. These tools work well on tough metals, making them perfect for building machines. They also help in making parts for furniture. So, if you see a car or a toy, bimetal cutters probably helped make it!