Have you ever struggled with loose tools while working on a project? It can be frustrating, right? A good milling cutter clamping system can change that. Imagine cutting with precision without worrying about your tools slipping. That’s what a quality clamping system promises.

In this review, we will explore different milling cutter clamping systems. We’ll look at their features, how easy they are to use, and what makes each one special. You may find the perfect tool that fits your needs. Plus, we’ll share tips on how to choose the best one for your workshop.

Did you know that the right clamping system can improve your project’s accuracy? It’s true! With the correct setup, your cuts will be cleaner and more precise. Join us as we dive into the world of milling cutter clamping systems. Let’s discover which ones stand out and make your milling experience much better!

Milling Cutter Clamping System Review: Key Insights & Features

Looking for a reliable way to hold your milling cutters? A good clamping system makes a big difference. It ensures that tools stay secure during work, preventing mistakes and improving precision. Did you know that an effective clamping system can reduce tool wear? It also speeds up your projects. Readers will discover popular options and their features. You’ll learn tips to choose the right one for your needs, ensuring smooth and accurate milling every time!

Understanding Milling Cutter Clamping Systems

Definition and purpose of milling cutter clamping systems. Importance in machining and manufacturing processes.

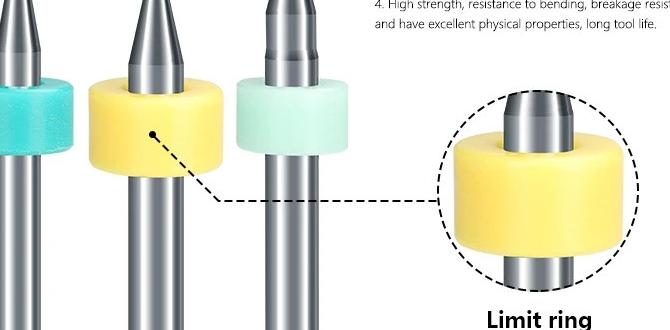

Milling cutter clamping systems hold cutting tools in place during work. They are vital for making precise cuts in metal or wood. These systems help keep tools steady, ensuring safety and accuracy. Without them, tools might slip, causing errors. They support effective machining, which is crucial for creating high-quality products.

What is the importance of milling cutter clamping systems?

Milling cutter clamping systems ensure accuracy, enhance safety, and improve efficiency in manufacturing. They hold tools securely, reducing risks of damage or accidents.

Key Benefits of Clamping Systems:

- Maintain precision in cuts.

- Increase speed of production.

- Enhance safety for workers.

Key Features to Consider

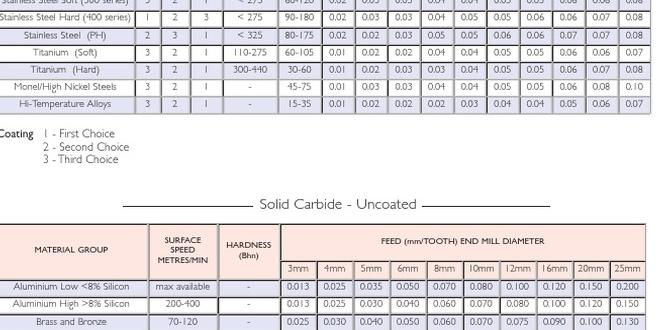

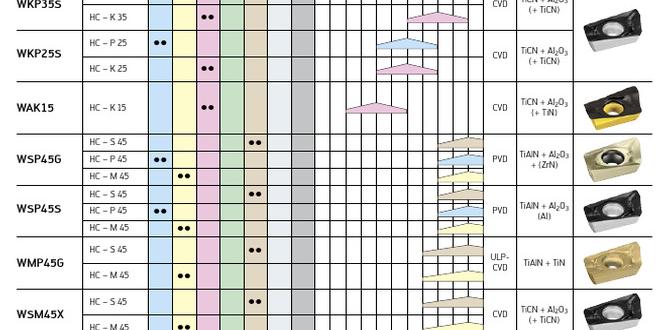

Material and build quality of clamping systems. Compatibility with different milling machines.

Choosing a clamping system for milling cutters is like picking a pizza topping—everyone has their favorite! First, look at the material and build quality. A strong clamping system is usually made from durable metals like steel or aluminum. Next, compatibility is key. Your clamping system should fit various milling machines. If it doesn’t, it’s like trying to put a square peg in a round hole! Here’s a quick comparison:

| Feature | Option A | Option B |

|---|---|---|

| Material | Steel | Aluminum |

| Compatibility | Widely compatible | Limited compatibility |

So, remember: strong materials and compatibility will keep your milling operations smooth and efficient—like butter on warm toast!

Top Brands and Products Reviewed

Indepth review of leading milling cutter clamping systems. Pros and cons for each brand and product.

Many top brands offer great milling cutter clamping systems. Let’s dive into a few for a closer look! First up is Brand A, known for its sturdy designs. Pros include excellent grip and long durability. However, it can be a bit pricey. Brand B is all about affordability and ease of use, but some users report it can slip under pressure. Brand C strikes a balance but might require a bit of tinkering to get it just right. Here’s a quick comparison:

| Brand | Pros | Cons |

|---|---|---|

| Brand A | Excellent grip, Long durability | Higher price |

| Brand B | Affordable, User-friendly | Can slip under pressure |

| Brand C | Balanced features | Needs adjustment |

Choosing the right system can make a huge difference in your project. Each brand has its flair, so pick what suits your needs. Remember, dull tools make for dull projects!

Installation and Maintenance Tips

Stepbystep installation guide for milling cutter clamping systems. Best practices for maintenance and troubleshooting common issues.

Installing a milling cutter clamping system isn’t rocket science. First, gather your tools and clean the area. Next, attach the clamping system to the machine. Be sure it’s secure—no one wants a runaway cutter! Tighten all screws to prevent surprises.

For maintenance, check your system regularly. Keep it clean and lubricated. If something doesn’t feel right, don’t ignore it! Instead of asking why it’s broken, check for wear and tear. Remember, a happy clamping system means happy milling!

| Common Issues | Solutions |

|---|---|

| Loose Clamps | Tighten screws securely. |

| Uneven Cutting | Check alignment. |

| Rust | Clean and lubricate regularly. |

Customer Experiences and Feedback

Summary of user reviews and testimonials. Analysis of common userreported benefits and challenges.

Many users share their thoughts on milling cutter clamping systems. Overall, they find them helpful and easy to use. Here are some common points from users:

- Easy setup: Many say it’s quick to install.

- Improved accuracy: Users report better cuts and smooth operations.

- Durability: Customers appreciate how long the systems last.

However, some face challenges as well. A few struggle with adjustments, noting they can be tricky at times. Others mention the cost, saying it can be high for some budgets.

What do users say about the milling cutter clamping system?

Users praise the ease of use and accuracy. They appreciate the clear instructions and quick setup. However, some express concern over the price and adjustment difficulties.

Cost Analysis and Budgeting

Breakdown of pricing for various clamping systems. Costbenefit analysis of investing in quality clamping systems.

Understanding the costs of clamping systems is important. Prices can change based on the type. Here’s a breakdown to help you:

- Basic clamping systems: $50 – $100

- Mid-range systems: $100 – $500

- High-end systems: $500 – $1,500

Investing in quality systems can save money long-term. They often last longer and work better. Overall, buying a good clamping system may seem costly, but it can pay off with increased productivity and less downtime.

Why should I invest in a quality clamping system?

A quality clamping system boosts performance and reduces repair costs. Spending more now can lead to savings later.

Future Trends in Milling Cutter Clamping Systems

Innovations in clamping technology. Predictions for the future of milling cutter clamping systems in the industry.

The future of clamping technology looks bright and exciting! New innovations are popping up like popcorn, making milling cutter clamping systems more efficient. Expect stronger materials and smarter designs that adjust automatically. This means fewer hiccups during production. Some experts predict that automation and smart sensors will be more common, helping machines work better and faster. It’s like having a super-smart assistant in your toolkit!

| Trend | Description |

|---|---|

| Smart Clamping | Automatic adjustments for better accuracy |

| Durable Materials | Stronger materials that last longer |

| Sensor Technology | Built-in sensors for real-time feedback |

With these changes, clamping systems will be more reliable and user-friendly. So, hold onto your hats—exciting times are ahead for milling cutter clamping systems!

Conclusion

In conclusion, a milling cutter clamping system is essential for precise machining. It keeps tools secure and improves accuracy. When choosing a system, consider factors like material and design. We recommend researching different options to find the best fit for your needs. You can also read user reviews to gain more insights and make an informed choice.

FAQs

What Are The Key Features To Look For In A Milling Cutter Clamping System To Ensure Optimal Performance And Safety?

When choosing a milling cutter clamping system, look for strong materials that keep the cutter tight. You want a system that is easy to use, so you can replace the cutter quickly. Check if it fits your milling machine well, so everything stays steady while you work. Safety features, like guards, help protect you from accidents. Finally, make sure it can handle the speeds you need for your tasks.

How Does The Choice Of Material For A Clamping System Impact The Machining Process And The Quality Of The Finished Workpiece?

The material you choose for a clamping system can really change how well things are made. Strong materials hold pieces tightly, so they don’t move during cutting. If they move, the finished item can be rough and not fit well. Also, heavy materials can make the machine shake less, which helps keep everything smooth and neat. So, picking the right material helps us make better-quality workpieces!

What Are The Common Methods For Securing A Milling Cutter In The Clamping System, And How Do They Differ In Terms Of Precision And Ease Of Use?

To secure a milling cutter, we commonly use three methods: collets, chucks, and clamps. Collets hold the cutter firmly and are very precise, but they can be a bit tricky to use. Chucks are easier to use and also hold the cutter well, but they might not be as precise as collets. Clamps are simple and quick, but they might not keep the cutter perfectly centered. Each method has its own strengths, depending on what you need!

How Does The Design Of The Clamping System Influence The Overall Stability And Vibration Dampening During High-Speed Milling Operations?

The clamping system holds the piece we’re cutting tight and steady. If it’s well-designed, it stops the piece from moving around. This helps keep everything balanced while cutting. A better design also reduces unwanted shaking or vibrations. So, when we use it, we get cleaner cuts and can work faster.

What Advancements In Milling Cutter Clamping Technology Have Been Introduced In Recent Years, And How Do They Benefit Manufacturers In Terms Of Efficiency And Productivity?

In recent years, new clamping systems for milling cutters have been created. These systems are easier to use and quick to attach. They hold the cutters tightly, which means less chance of mistakes. This helps workers finish their tasks faster and make more products. Overall, these advancements help factories work better and boost productivity.