Milling cutters are vital tools in CNC machines. They help shape and cut materials accurately. But have you ever wondered how a CNC machine knows when to change its milling cutter? The timing of tool changes is crucial for creating precise and efficient parts.

Imagine you are building a complex puzzle. Each piece must fit perfectly. If you have the wrong piece, it won’t work! The same applies to CNC milling. Using the right cutter at the right time makes all the difference.

Did you know that even a small delay in changing the cutter can lead to big mistakes? This is why understanding milling cutter CNC tool change timing is essential. It not only saves time but also ensures the highest quality in every project.

In this article, we will explore how precise timing in tool changes can make a huge impact on your CNC milling projects. Buckle up and dive into the world of CNC machining!

Milling Cutter Cnc Tool Change Timing: Optimizing Efficiency

Milling Cutter CNC Tool Change Timing

Milling cutter CNC tool change timing is vital for efficient machine operation. Proper timing reduces downtime and improves production speed. Did you know that a well-timed tool change can save hours in a production week? Factors like tool type, material, and machine speed influence this timing. Adjusting these elements can lead to smoother operations and better product quality. Understanding these aspects helps machinists optimize their workflow and enhance overall performance. How can this knowledge boost your CNC projects?Understanding CNC Tool Change Mechanisms

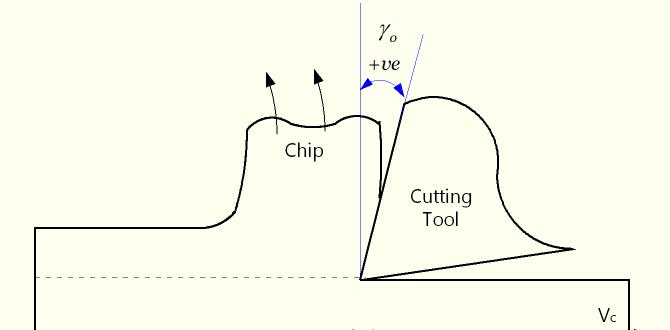

Explanation of different CNC tool change types (manual, automatic).. Importance of tool change timing in milling operations..CNC machines are like superheroes in the workshop, and tool changes are their quick costume swaps! There are two main types of tool changes: manual and automatic. In manual changes, operators switch tools by hand—like changing a light bulb. Automatic changes use fancy robotics to swap tools quickly, letting machines save time and keep milling! The timing of these changes is crucial. A well-timed tool swap can make operations smoother and faster, like a game of catch with no dropped balls!

| Type of Tool Change | Description |

|---|---|

| Manual | Operator changes tools by hand. |

| Automatic | Machine changes tools using robotics. |

Factors Affecting Tool Change Timing

Influence of machine design and architecture on change speed.. Operator skill level and its impact on timing..Many things affect how fast machines change tools. First, the design of the machine plays a big role. Better designs make changes happen quicker. Next, the operator’s skill level matters a lot. A skilled operator can change tools faster and with fewer mistakes. This means that both machine design and operator skill work together to speed up tool changes.

How do machine design and operator skills affect tool change speed?

Machine design influences speed by allowing fast access to tools. A skilled operator also performs quicker tool changes. It’s not just the machine; it’s the person using it too!

Factors to consider:

- Machine design style

- Ease of tool access

- Operator training and experience

- Type of tools used

Best Practices for Scheduling Tool Changes

Techniques for predicting tool wear and optimal change intervals.. Strategies for minimizing downtime during tool changes..To keep machines running smoothly, it’s crucial to change tools at the right time. Predicting tool wear helps set the best change intervals. Monitor the cutting edge closely. Tools may show signs of wear, like rough cuts or increased noise. Keeping a log helps too.

To reduce downtime during changes, follow these tips:

- Have spare tools ready.

- Train staff on quick replacements.

- Schedule changes during breaks or shifts.

Smart scheduling boosts production. Remember, a good plan means less waiting and more working!

How can you tell when to change tools?

Look for changes in cutting speed and finish quality. That often means it’s time for a new tool!

Case Studies: Tool Change Timing in Action

Analysis of realworld examples showcasing improved efficiency.. Lessons learned from industry leaders and their tool change strategies..Real-world examples show how smart tool change timing can boost factory speed. Companies that focus on this see faster production and less downtime. For instance, one manufacturer improved output by 20% after optimizing their tool change. Here are some lessons learned:

- Plan Ahead: Know when to change tools.

- Stay Updated: Use the latest tech for tool changes.

- Gather Data: Track timings and adjust as needed.

How do industry leaders improve tool change timing?

Industry leaders use strategies like precise scheduling and training workers. This helps reduce delays.Key Points to Remember:

- Regular training keeps staff sharp.

- Investing in better tools cuts change time.

Challenges in Tool Change Timing

Common obstacles encountered in the tool change process.. Solutions to address and mitigate timing issues..Tool changes in a CNC machine can face many problems. Some common issues include misalignment of tools, incorrect timings, or machinery lag. These can slow down work and cause mistakes. To fix these problems, try the following:

- Regular Maintenance: Keep tools and machines clean and well-oiled.

- Set Timers: Use timers to schedule tool changes precisely.

- Practice: Train staff to handle tools efficiently.

What are the impacts of tool change timing delays?

Delays in changing tools can lead to wasted materials and longer production times. This can also increase costs and lead to unhappy customers. Good timing helps everything run smoothly.

Future Trends in CNC Tool Change Technologies

Exploration of anticipated technological advancements affecting tool change.. Predictions on how AI and machine learning may optimize tool change timings..The future of CNC tool changes looks bright! With advancements like AI and machine learning, we expect faster, smarter transitions. Imagine a robot that can swap tools quicker than you can say “milling cutter”! Manufacturers predict that AI will analyze data to suggest the best tool change timings, boosting efficiency. In fact, studies suggest that automated systems could reduce tool change time by up to 30%. Now that’s what we call a time-saver!

| Future Trends in CNC | Impact on Tool Change |

|---|---|

| AI Integration | Optimized timing and selection |

| Machine Learning | Faster adjustments |

| Robotics | Quicker tool swaps |

Conclusion

In summary, knowing about milling cutter CNC tool change timing can help you improve your machining efficiency. It affects your production speed and accuracy. By planning changes well, you can save time and reduce errors. We encourage you to explore more about this topic. Understanding it better can make your projects easier and more successful. Happy learning!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Cnc Tool Change Timing:Sure! Milling cutters are tools that help machines cut shapes from materials. When we talk about CNC (Computer Numerical Control) tools, they can change automatically. It’s important to know how long it takes for a tool to switch. Good timing helps make sure your work is done correctly and quickly. You want the machine to work smoothly without delays.

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Optimal Timing For Tool Changes During Cnc Milling Operations?When you use a CNC milling machine, the tool can get dull over time. The type of material you’re cutting affects how quickly this happens. If you notice poor cut quality or unusual sounds, it’s time to change the tool. Also, you should consider how many pieces you need to make before switching tools. By paying attention to these signs, you can change tools at the right time.

How Can Tool Change Timing Impact Overall Machining Efficiency And Production Throughput?Tool change timing is how long it takes to switch from one tool to another during work. If we change tools quickly, we keep making parts fast. But if it takes too long, we stop working and lose time. This means we can make fewer items in the same hour. So, fast tool changes help us work better and produce more!

What Are The Common Methods Or Systems Used To Automate Tool Changes In Cnc Milling Machines?To automate tool changes in CNC milling machines, we often use tool changers. These are special devices that grab a tool and swap it for another. There are also magazine systems that hold extra tools nearby. Some machines use robotic arms to do the changes quickly. This helps us work faster and with less effort!

How Does The Choice Of Milling Cutter Material Affect The Frequency And Timing Of Tool Changes In Cnc Machining?The material of the milling cutter decides how long it lasts before we need to change it. If we use a strong cutter, it can cut for a longer time. But if we use a weaker cutter, we have to change it more often. Changing tools takes time, so better cutters help us work faster. This means we can make more parts without stopping as much.

What Role Does Advanced Cnc Programming Play In Optimizing Tool Change Timing For Complex Milling Operations?Advanced CNC programming helps machines change tools quickly and smartly. This saves time during complex milling tasks. When we program these machines well, they know exactly when to switch tools. It makes the whole process smoother and faster. So, you get better work done in less time!