Have you ever wondered how long a milling cutter can last? Imagine working on a big project, only to have your tools wear out quickly. This is where milling cutter coating durability benchmarks come in. These benchmarks tell us how strong and long-lasting coatings are. They help everyone from hobbyists to professionals to choose the best tools.

In a world where every second counts, durability is key. A strong milling cutter can turn a long day of work into a smooth success. Did you know that some coatings can make a cutter last up to five times longer? It’s true! Understanding these durability benchmarks can help you make smart choices.

So, what makes certain coatings better than others? Are there specific tests that measure how well they hold up? In this article, we’ll explore the science behind milling cutter coatings. We will talk about the tests that show their strength and longevity. Get ready to discover tips that could make your next project seamless and fun!

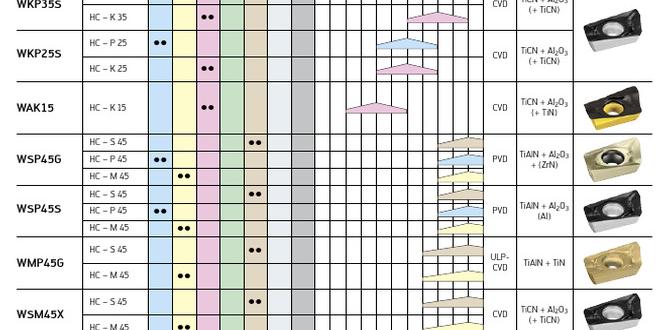

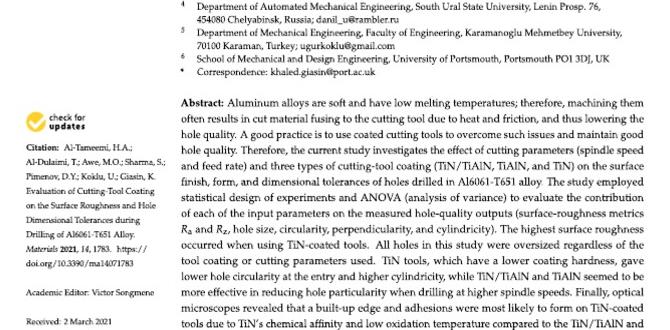

Milling Cutter Coating Durability Benchmarks: Insights & Standards Milling Cutters Are Essential Tools In Machining Processes, And Their Performance Largely Depends On The Durability Of Their Coatings. As The Industry Pushes For Higher Efficiency And Longer Lifespan From These Tools, Understanding The Benchmarks For Coating Durability Becomes Crucial. In This Article, We Will Delve Into The Various Aspects That Define Milling Cutter Coating Durability Benchmarks, The Technologies Involved, And Their Impact On Machining Performance. What Are Milling Cutter Coating Durability Benchmarks? Milling Cutter Coating Durability Benchmarks Refer To The Standards And Metrics Used To Evaluate The Lifespan, Wear Resistance, And Effectiveness Of Coatings Applied To Milling Cutters. These Benchmarks Help Manufacturers And Users In Selecting The Appropriate Coating For Specific Applications, Ensuring Optimal Performance And Reducing Tool Wear. Importance Of Coating Durability The Durability Of A Milling Cutter Coating Significantly Affects The Cutting Performance, Tool Life, And Overall Cost-Effectiveness Of Machining Operations. A Durable Coating Minimizes Friction And Allows For Better Heat Dissipation, Thereby Preventing Tool Deformation And Ensuring A Cleaner Cut. Consequently, Selected Coatings That Meet Or Exceed Established Durability Benchmarks Can Lead To Increased Productivity And Lower Operational Costs. Factors Affecting Coating Durability Several Factors Influence The Durability Of Milling Cutter Coatings: 1. **Material Of The Coating**: Different Coating Materials (E.G., Tialn, Tin, And Diamond-Like Carbon) Exhibit Varying Wear Resistance And Thermal Stability. Understanding The Properties Of Each Material Is Crucial In Determining Suitability For Specific Applications. 2. **Coating Thickness**: Thicker Coatings Can Provide Better Durability But May Also Affect Cutting Performance. It Is Essential To Strike A Balance Between Coating Thickness And Operational Efficacy. 3. **Coating Process**: The Manufacturing Process Used For Applying The Coating Plays A Significant Role In Determining Its Durability. Techniques Like Physical Vapor Deposition (Pvd) Or Chemical Vapor Deposition (Cvd) Can Impact The Bonding Strength And Overall Quality Of The Coating. 4. **Workpiece Material**: The Type Of Material Being Machined Can Also Affect The Wear Rate Of The Coating. Harder Materials May Subject The Coating To Increased Stress, Thus Impacting Longevity. Key Benchmarks For Evaluation To Evaluate Milling Cutter Coating Durability, Several Benchmarks Can Be Employed: – **Wear Rate**: Measured In Micrometers Per Minute, A Lower Wear Rate Indicates Better Durability. – **Tool Life**: The Number Of Parts Machined Or The Amount Of Material Removed Before The Coating Starts To Degrade Is A Crucial Benchmark. – **Surface Finish**: The Quality Of The Surface Finish Produced During Machining Reflects The Coating’S Effectiveness. Consistently Achieved Target Surface Roughness Is A Good Durability Indicator. – **Heat Resistance**: Coatings That Maintain Their Integrity And Performance At Elevated Temperatures Demonstrate Proven Durability. Conclusion Milling Cutter Coating Durability Benchmarks Serve As Vital Guidelines For Selecting And Evaluating Milling Cutter Tools In Machining Operations. By Understanding The Factors That Influence Coating Durability And The Key Benchmarks Used For Assessment, Manufacturers And Users Can Make Informed Decisions That Will Enhance Operational Efficiency And Tool Longevity. As Technology Evolves, Staying Abreast Of The Latest Advancements In Coating Materials And Application Methods Will Further Ensure That These Benchmarks Continue To Meet Industry Demands.

Milling Cutter Coating Durability Benchmarks

Milling cutter coatings play a crucial role in tool performance and lifespan. They enhance durability, reduce wear, and improve cutting efficiency. Did you know that different coatings offer varying levels of resistance to heat and corrosion? Benchmarks help users choose the right coating based on their specific needs. Understanding these benchmarks can lead to longer-lasting tools and cost savings. With the right choice, you can cut without worry, maximizing productivity in your projects.Understanding Milling Cutter Coatings

Definition and purpose of milling cutter coatings.. Types of coatings commonly used in milling cutters..Milling cutter coatings are special layers that protect the tools from wear and tear. Their purpose is to increase tool life and improve cutting efficiency. Different coatings help in different ways, such as reducing friction and heat. Here are some common types of coatings:

- Titanium Nitride (TiN): Offers good wear resistance and lower friction.

- Titanium Carbide (TiC): Known for its hardness and durability.

- Titanium Aluminum Nitride (TiAlN): Great for high-temperature tasks.

Using the right coating can help achieve better performance in milling tasks.

What are milling cutter coatings used for?

Milling cutter coatings are used to protect tools, extend their life, and improve cutting performance. They make cutting easier and faster by reducing friction and heat.

Factors Affecting Coating Durability

Material composition and its impact on durability.. Environmental factors that influence coating longevity..Many things affect how long a coating will last. The material composition is one major factor. Different materials react differently, which can change how well the coating holds up. Stronger materials usually make coatings last longer.

Environmental factors also play a big role. Things like heat, cold, and humidity can harm the coating. It’s essential to know these conditions before using a milling cutter. When you understand these factors, you can make better choices.

What materials impact coating durability?

High-quality materials can improve durability. For instance, titanium nitride is stronger than regular steel.

Key environmental factors:

- Heat

- Moisture

- Dust and grime

Comparison of Coating Durabilities Across Materials

Analysis of different coatings (TiN, TiAlN, etc.) and their lifespan.. Case studies comparing performance in various machining conditions..Coatings like TiN and TiAlN are popular for milling cutters. They protect tools from wear and tear, extending their life. For example, TiN can last up to twice as long compared to uncoated tools. TiAlN offers high heat resistance, making it ideal for tough jobs. In different machining conditions, performance varies. Some studies show that a TiAlN coating shines in high-speed operations, while TiN is best in softer materials. Here’s a quick look at how they stack up:

| Coating Type | Average Lifespan | Best Use |

|---|---|---|

| TiN | 1,200 minutes | Soft Materials |

| TiAlN | 1,800 minutes | High-Speed Machining |

Choosing the right coating can feel like a matchmaking quest. Remember, tools are like people—some just work better together!

Industry Standards and Benchmarks

Key industry standards for measuring coating durability.. Benchmarking against competitors and top performers in the market..Measuring coating durability in milling cutters is like a contest of toughness! Key industry standards, like ISO and ASTM, help keep things fair. They set guidelines to test how well coatings withstand wear, tear, and more.

To know who’s the best, companies benchmark their products against top competitors. This shows how a milling cutter stacks up in coating performance. It’s like a race to see which cutter shines the brightest!

| Standard | Description |

|---|---|

| ISO 1302 | Focuses on surface texture and quality |

| ASTM B117 | Measures salt spray corrosion resistance |

| ASTM G65 | Tests wear resistance during abrasive conditions |

So, when choosing a milling cutter, check those benchmarks. They tell you which cutter is worthy of your hard work. Remember, a tough coating means less downtime and a happier you!

Best Practices for Maximizing Coating Life

Recommended machining parameters and strategies.. Maintenance and care for extending cutter life..To help your milling cutters last longer, follow these smart tips. First, choose the right settings when cutting. Use lower speeds and feeds for harder materials. This can prevent damage. Keep your cutters clean. Dirt can wear them down quickly. Lubricate them regularly to reduce friction. Lastly, always inspect them for wear. Taking good care of your tools will keep them sharp and effective.

How can I maximize my milling cutter’s coating life?

To maximize coating life, maintain proper speeds, clean regularly, and inspect for damage.

Recommended practices include:

- Use lower speeds and feeds on hard materials

- Regularly clean cutters to remove debris

- Lubricate to minimize wear

- Inspect for any signs of wear or damage

Emerging Technologies in Coating Development

Innovations in coating materials and applications.. Future trends in milling cutter coatings and durability expectations..New ideas are making coating materials better. Scientists explore new properties for coatings. These innovations can help milling cutters last longer. For example, some coatings resist wear and tear better than older types.

Looking forward, we expect coatings to get even stronger. Many experts believe future coatings will have improved durability. This could mean less time spent replacing tools. The future looks bright for milling cutter coatings!

What are the key trends in milling cutter coatings?

Trends include strong coatings that last longer and cost-effective options that improve efficiency.- More wear resistance

- Better heat resistance

- Eco-friendly materials

Conclusion

In summary, milling cutter coating durability benchmarks help you choose the best tools for your projects. Strong coatings last longer and improve performance. Testing helps identify quality options. We recommend researching different coatings and comparing their durability. This way, you ensure your tools work efficiently. Explore more about coatings to make the smartest choices for your work!FAQs

What Are The Most Common Types Of Coatings Used On Milling Cutters, And How Do Their Properties Influence Durability?The most common coatings for milling cutters are titanium nitride (TiN), titanium carbonitride (TiCN), and chromium nitride (CrN). These coatings help the cutters last longer. They make the cutters tougher and reduce friction. Because of this, we can cut metal better and more easily without breaking the tools. Coated tools stay sharp and work well for a long time.

How Do Various Milling Processes (E.G., Roughing Vs. Finishing) Affect The Longevity Of Coated Milling Cutters?Roughing is when we quickly remove a lot of material. This process can be hard on coated milling cutters. It makes them wear out faster. Finishing is slower and smoother, which is easier on the cutters. Because of this, coated milling cutters last longer when we use them for finishing.

What Standardized Tests Or Benchmarks Are Typically Used To Evaluate The Durability Of Milling Cutter Coatings?To test how long milling cutter coatings last, we use different methods. One common test is called a wear test. In this test, we check how much the coating wears off after cutting materials. Another way is using a scratch test, which sees how easily the coating can be scratched. These tests help us understand which coatings are the best.

How Do Factors Such As Cutting Speed, Feed Rate, And Material Type Impact The Performance And Lifespan Of Coated Milling Cutters?Cutting speed is how fast you move the cutter. Faster speeds can make the cutter wear out quickly. Feed rate is how much material you remove each time. Taking too much can break the cutter. The material type matters too—harder materials can dull the cutter faster. Overall, these factors help the cutter work better and last longer if you choose the right ones.

Are There Any Emerging Technologies Or Advancements In Coating Materials That Promise To Enhance The Durability Of Milling Cutters In High-Performance Applications?Yes, there are new coating materials that make milling cutters stronger and last longer. Some coatings use special ceramics or super-hard materials. These make the cutters resist heat and wear during tough jobs. This means we can cut faster and save money by not replacing tools as often.