Have you ever wondered how machines create perfect shapes? One key tool in this process is the milling cutter. It shapes materials with precision. But how do we know if it does its job well? That’s where the milling cutter contour accuracy test comes in.

This test ensures that the cutter makes the right shapes every time. Imagine a toy car with perfectly round wheels. If the cutter isn’t accurate, those wheels won’t fit right. It’s important for safety and performance.

Did you know that even tiny errors can cause big problems? A small mistake in cutting can lead to wasted materials and time. That’s why testing accuracy is crucial. By examining how well the cutter performs, we can keep machines running smoothly.

Join us as we explore the world of milling cutter contour accuracy tests. Discover why this test is so important and how it helps create the products we use every day!

Milling Cutter Contour Accuracy Test: Ensuring Precision

Milling Cutter Contour Accuracy Test

Milling cutter contour accuracy tests measure how precisely a cutter shapes materials. These tests ensure that tools can produce the exact shapes needed for projects. Did you know a single millimeter can make a big difference in machining? Accurate cutters improve efficiency and reduce waste. By understanding how to test for accuracy, engineers can choose the best tools for their tasks. Whether in a factory or a DIY project, accuracy pays off!Understanding Milling Cutter Contour Accuracy

Definition of milling cutter contour accuracy. Importance in manufacturing and machining processes.Milling cutter contour accuracy tells us how well a cutter shapes materials. It’s like checking if a cookie cutter actually makes the right shape. This accuracy is super important in manufacturing. If a cutter isn’t precise, products might not fit together. Imagine building a puzzle with pieces that don’t match—frustrating, right? Good accuracy means higher quality and happier workers and customers! It’s a win-win situation! Let’s break it down in the table below:

| Aspect | Importance |

|---|---|

| Cutter Precision | Ensures parts fit well |

| Quality Control | Reduces mistakes |

| Production Efficiency | Saves time and money |

Factors Affecting Contour Accuracy in Milling Cutters

Discussion of material properties. Impact of cutter design and geometry.Milling cutters are important tools for shaping materials. Their accuracy can change based on different factors. Key among these are material properties and cutter design. The type of material affects how well the cutter performs. Harder materials can wear down cutters quickly. The shape and style of the cutter also matter. A good design leads to better accuracy. A sharp edge helps create clean cuts, while poor design leads to mistakes.

What affects the contour accuracy of milling cutters?

Material properties like hardness and toughness play a big role. Cutter design also influences accuracy. A well-designed cutter cuts smoother and more precise than a poorly designed one.

Key Factors:

- Material hardness affects wear and tear.

- Shape affects cutting efficiency.

- Edge sharpness impacts cut quality.

Testing Methods for Contour Accuracy

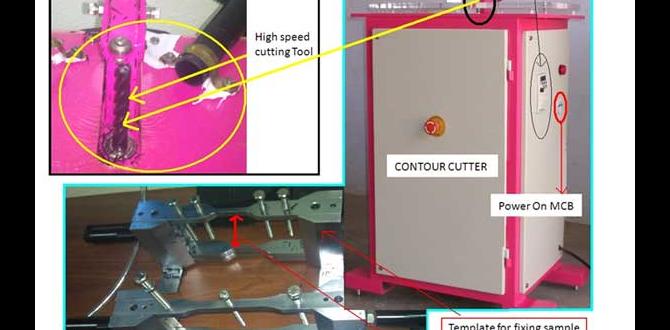

Description of common testing techniques. Pros and cons of each method.Testing milling cutter contour accuracy involves several methods. Each has its own benefits and drawbacks. Here are some common techniques:

- Laser Measurement: Fast and precise, but can be costly and requires special setup.

- Physical Templates: Easy to use and inexpensive. However, they can be less accurate for complex shapes.

- Coordinate Measuring Machines (CMM): Highly accurate and versatile. Yet, they need skilled operators and can be slow.

Choosing the right method depends on your needs and budget. Always consider what matters most for your testing!

What is the best method for testing contour accuracy?

The best method is laser measurement due to its speed and precision, especially for complex cuts. However, costs and setup time can be a factor.

Industry Standards and Certifications

Relevant standards for testing contour accuracy. Importance of compliance for quality assurance.Many industries have rules for testing the milling cutter contour accuracy. These rules help ensure the tools work correctly. When tools follow these standards, products are made safely and with fewer mistakes. This is important for keeping customers happy. Here are some key points:

- Standards vary by industry.

- Complying boosts product quality.

- Regular tests confirm accuracy.

Staying compliant also helps companies gain trust. It shows they care about making quality products.

What are the relevant standards for testing contour accuracy?

ISO 9001 is one standard that ensures quality management. Other standards like ISO 1101 focus on geometric tolerancing.

Interpreting Test Results

Key metrics for evaluating contour accuracy. How to analyze and report findings.Understanding the results of a milling cutter contour accuracy test is important. Key metrics help measure how precise the cutter is. These include:

- Dimensional accuracy: How close the finished part is to the desired size.

- Surface finish: The smoothness of the cutter’s surface.

- Consistency: How repeatable the results are over time.

To analyze and report findings, organize data clearly. Charts and graphs can help show trends. Use simple language to explain what the data means. This way, everyone understands the results easily.

What are key points to consider when evaluating contour accuracy?

Key points include dimensional accuracy, surface finish, and consistency. These metrics give a clear picture of how well the milling cutter performs.

Improving Milling Cutter Contour Accuracy

Techniques for enhancing accuracy during production. Role of technology and software in precision machining.To strengthen milling cutter contour accuracy, we can use various techniques. First, precise tool paths are essential. Using advanced software for design helps achieve this. Next, regular machine maintenance can prevent errors. High-quality materials also play a big role in accuracy. The right settings on machines can make a huge difference too.

- Use advanced software to plan tool paths.

- Maintain machines regularly.

- Choose high-quality materials.

- Adjust machine settings carefully.

Technology helps in precision machining. With modern tools, manufacturers boost accuracy. Software can model cuts before production starts. It allows for real-time tracking of the milling process. This ensures everything stays on target.

What are some ways to enhance milling cutter accuracy?

Precision planning, machine upkeep, and high-quality materials can greatly improve milling cutter accuracy.Case Studies and Real-World Applications

Examples of successful contour accuracy tests. Lessons learned from industry implementation.Many companies have successfully tested milling cutter contour accuracy. For example, a well-known auto parts company improved their tools by 30% after testing. They learned to check cutting paths carefully. Another tech firm increased precision and reduced waste by 25%. These tests showed how important accuracy is in everyday processes.

- Improved the quality of products.

- Reduced production waste.

- Saved time and costs.

These case studies highlight key lessons for other industries. Testing is vital for success. It’s not just about tools but about using them wisely.

What are the benefits of conducting a milling cutter contour accuracy test?

Benefits include improved product quality, reduced waste, and cost savings. Companies learn to use their tools better and create more reliable products.

Conclusion

In summary, a milling cutter contour accuracy test helps ensure precision in shaping materials. Understanding this test can improve your machining skills. Always check your tools for accuracy before starting a project. You can explore more about milling processes and techniques to enhance your knowledge. Remember, practice makes perfect, so keep experimenting and learning!FAQs

What Methods Are Commonly Used To Assess The Contour Accuracy Of Milling Cutters During Manufacturing?To check how well milling cutters are made, we can use a few methods. First, we can measure them with special tools that tell us their exact size and shape. Next, we can run tests to see if they cut materials correctly. We can also compare them with a perfect model to find any differences. These steps help us make sure the cutters work well for their jobs.

How Does The Material Of The Milling Cutter Affect Its Contour Accuracy In Machining Applications?The material of the milling cutter affects how well it cuts shapes. If the cutter is strong, it keeps its shape better while cutting. We want the cutter to be sharp and not bend or break easily. This helps us make more accurate and smooth shapes in our projects. Softer materials can wear out quickly, leading to less precise cuts.

What Are The Key Parameters To Consider When Performing A Contour Accuracy Test On Milling Cutters?When we test how accurate milling cutters are, we should look at a few important things. First, check the cutter’s shape to see if it matches what we expect. Next, measure how deep it cuts into the material. We also need to see if it can follow curves smoothly without making mistakes. Finally, we should look at how well it stays sharp after use. All these steps help us know how good the cutter is at making things.

How Does The Cutter Geometry Influence The Overall Contour Accuracy In Different Milling Processes?The shape of the cutter affects how well it carves out shapes. If the cutter has sharp edges and the right angles, it makes cleaner cuts. This helps us get the exact shapes we want. When we change the cutter shape, it can change how smooth or rough the final piece is. So, a good cutter shape means better accuracy in our work.

What Are The Implications Of Poor Contour Accuracy On The Quality Of The Final Machined Products?Poor contour accuracy means shapes aren’t made correctly. This can lead to parts that don’t fit together well. You might find gaps or uneven edges. When pieces don’t match, the final product can be weak or break easily. Overall, it makes the finished item low quality and less useful.