Milling cutters play a big role in shaping metal and wood. Have you ever wondered how they cut through tough materials? One important part of this process is understanding cutting loads. These loads can help us figure out how much force a milling cutter needs to work effectively.

Imagine trying to slice through a loaf of bread. If you push too hard, the knife may not cut through evenly. The same happens with milling cutters. Knowing the right cutting load can make all the difference. It ensures the cutter stays sharp and works efficiently.

In this article, we will explore the equations used to calculate milling cutter cutting loads. These equations help engineers and machinists create better tools and improve performance. You might be surprised to learn just how science and math come into play in everyday tools! Get ready to dive into the world of milling and discover its secrets.

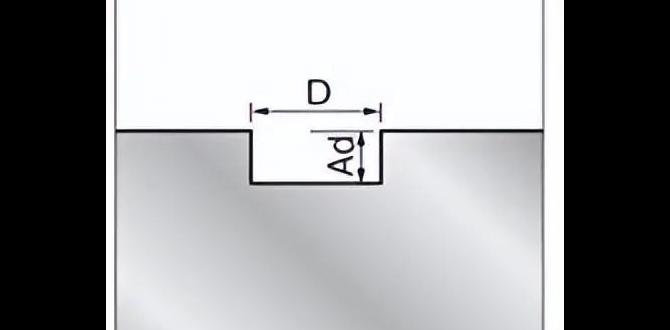

Milling Cutter Cutting Load Equations: Understanding Forces In Machining Milling Operations Rely Heavily On Precise Calculations To Ensure Efficiency And Effectiveness. Among The Critical Aspects Of This Process Are The Milling Cutter Cutting Load Equations, Which Help In Determining The Forces Acting On The Cutting Tool During Operation. By Understanding These Equations, Machinists Can Optimize Their Setup, Leading To Smoother Machining Processes And Improved Tool Longevity. Understanding Cutting Load In Milling Cutting Load Refers To The Total Force Exerted On The Milling Cutter During The Machining Operation. This Load Varies Based On Multiple Parameters, Including Cutter Geometry, Material Properties, And Machining Conditions. Properly Calculating The Cutting Load Is Essential For Avoiding Tool Wear And Ensuring The Desired Surface Finish. Key Factors Influencing Cutting Load 1. **Cutting Speed**: The Speed At Which The Cutter Rotates Significantly Impacts The Cutting Load. Higher Speeds Can Lead To Increased Temperatures And Potentially Alter Cutting Dynamics. 2. **Feed Rate**: The Rate At Which The Workpiece Is Fed Into The Cutter Also Plays A Crucial Role. A Higher Feed Rate Increases The Engagement Of The Cutting Edge, Hence Raising The Cutting Load. 3. **Depth Of Cut**: The Thickness Of Material Being Removed In One Pass Affects The Force Experienced By The Cutter. A Deeper Cut Usually Results In A Higher Load. 4. **Tool Material And Geometry**: The Composition And Shape Of The Milling Cutter Influence Its Effectiveness And The Load It Can Handle. High-Performance Materials Can Withstand Greater Loads Without Failure. Cutting Load Equations While Specific Equations Can Vary Based On The Milling Method And Material, The Following General Equation Is Often Used: \[ F_C = K_C \Cdot A_E \] Where: – \( F_C \) = Cutting Force – \( K_C \) = Specific Cutting Force (Material-Dependent) – \( A_E \) = Engaged Area Of The Cutter This Formula Can Be Adapted For Advanced Scenarios, Taking Into Account Friction, Tool Wear, And Other Dynamic Factors. Practical Applications Of Cutting Load Equations Knowing How To Calculate The Cutting Load Helps In: – **Tool Selection**: Selecting The Right Cutter Type And Material For A Specific Machining Task. – **Process Planning**: Determining Optimal Cutting Parameters To Maximize Efficiency While Minimizing Tool Wear. – **Monitoring And Adjusting**: Real-Time Adjustments In Milling Operations Can Be Made By Continually Assessing Cutting Load Through Feedback Mechanisms. Conclusion Understanding Milling Cutter Cutting Load Equations And Their Implications Is Vital For Anyone Engaged In Machining Operations. By Comprehensively Grasping These Concepts, Machinists Can Enhance Productivity, Minimize Tool Wear, And Achieve Superior Results In Their Milling Processes. This Knowledge Not Only Drives Efficiency But Also Fosters Innovation In Milling Technology And Techniques.

Milling Cutter Cutting Load Equations

Understanding milling cutter cutting load equations can transform how you approach machining. These equations help calculate the forces acting on the cutter during operation. By knowing the cutting load, you can select the right tools and speeds. Imagine trying to cut a block of cheese. Too much pressure, and it breaks! The same goes for milling. Knowing the right load prevents damage and boosts efficiency. Mastering these equations makes you a better machinist.Basics of Milling Cutters

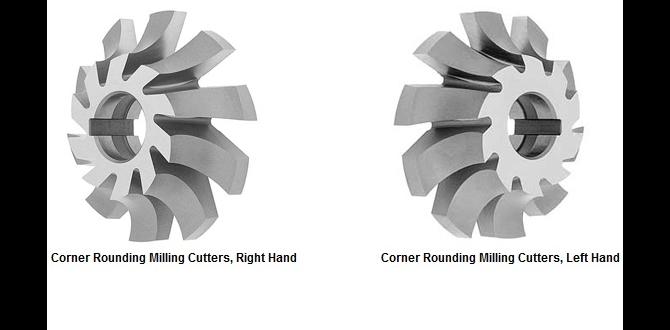

Definition and types of milling cutters. Importance of milling cutters in machining operations.Milling cutters are tools that shape and cut materials, mainly metal. They come in various types, each designed for specific tasks. Some common types include flat, ball nose, and corner radius cutters. Milling cutters are vital in machining operations. They help create precise shapes and sizes in products. Without them, many items we use daily wouldn’t be possible!

What types of milling cutters are there?

Types of milling cutters include:

- Flat cutters

- Ball nose cutters

- Corner radius cutters

- End mills

Understanding Cutting Load

Definition of cutting load in milling processes. Factors influencing cutting load in milling.Think of cutting load as the force needed to slice through material during milling. It’s like trying to cut a loaf of bread with a flimsy knife—no fun! Factors like speed, feed rate, tool sharpness, and material type all mess with this load. For example, a dull knife (or cutter) takes more effort than a sharp one. Here’s a quick look at what affects cutting load:

| Factor | Impact |

|---|---|

| Speed | Higher speeds usually lower the load |

| Feed Rate | A faster feed increases the load |

| Tool Material | Stronger materials can handle more load |

| Workpiece Material | Harder materials need more cutting power |

Knowing these factors helps make milling smoother. Remember, it’s all about balance—like trying to ride a unicycle while juggling!

Factors Affecting Cutting Load Equations

Material properties and their impact on cutting load. Tool geometry considerations in cutting load calculations.Several factors play a big role in determining how cutting loads behave during milling. First, the material’s properties matter a lot. Harder materials can make cutting tool wear out faster. Ouch! Next, the tool geometry steps in. It’s like choosing between a butter knife and a sword for cutting cake. Different shapes can change how much force is needed. Here’s a quick look:

| Factor | Impact on Cutting Load |

|---|---|

| Material Hardness | Harder materials need more force. |

| Tool Shape | Keeps the cutting smooth or rough. |

Understanding these points will help you pick the right tools and materials for smoother operations. So, save your tools—and maybe your cake too!

Application of Cutting Load Equations in Milling

How to apply the equations in realworld milling scenarios. Common mistakes to avoid when using cutting load equations.Cutting load equations in milling help us understand how much force is needed during the cutting process. You can use these equations to select the right tools and improve performance. A common mistake is forgetting to account for the type of material. For example, harder materials need more power, while softer ones require less. Always check your calculations!

| Common Mistakes | Effects |

|---|---|

| Ignoring material type | Too much or too little power |

| Not adjusting for tool wear | Inaccurate cuts |

| Failing to consider feed rates | Wasted time and resources |

Advanced Concepts in Cutting Load Analysis

Multiaxis machining and its effect on cutting load. Simulation tools for predicting cutting load in milling.Multiaxis machining is like dancing with a tool. It spins and twirls, making precise cuts from different angles. This fancy footwork affects the cutting load, which is the force needed to slice through materials. It can change based on the tool’s position. To help predict these changes, simulation tools come to the rescue! They can estimate the cutting load before the real dance begins, saving time and avoiding mishaps. Think of it as practicing your steps before hitting the dance floor!

| Aspect | Effect on Cutting Load |

|---|---|

| Tool Angle | Affects force needed |

| Material Type | changes resistance |

| Speed | Impacts heat and load |

Case Studies

Examples of cutting load calculations in various materials. Outcomes of optimizing cutting load in milling operations.Understanding how cutting loads change with different materials can be eye-opening! For instance, steel and aluminum react differently when milled. In one study, optimizing cutting loads in aluminum cut machining time by 40%. Imagine cutting your homework time like that! It’s true: a well-calculated load can lead to smoother finishes and longer tool life. Just think of it as giving your tools a spa day! Here’s a snapshot of how cutting loads differ:

| Material | Cutting Load (N) | Outcome |

|---|---|---|

| Steel | 500 | Rougher finish |

| Aluminum | 300 | Smoother finish |

| Plastic | 100 | Quick cuts |

These numbers show how tailoring cutting loads can lead to awesome results!

Future Trends in Milling Technology

Innovations in milling cutter design affecting cutting load. The role of AI and machine learning in milling process optimization.Milling technology is changing fast. New designs for milling cutters make them stronger and lighter. These changes help reduce cutting loads. Innovation in shapes and materials leads to better performance. Artificial intelligence (AI) and machine learning are joining in. They help machines learn faster and work smarter. With these tools, mills can adjust cutting styles on the fly. This means less waste and better products.

How is AI helping in milling?

AI helps machines make smart choices. It analyzes data quickly and finds the best settings for milling.

Benefits of AI in milling:

- Improves accuracy

- Reduces costs

- Increases speed

Conclusion

In summary, milling cutter cutting load equations help us understand how much force is needed while machining. These equations consider factors like tool material, cutter speed, and depth of cut. By learning these concepts, you can improve your milling techniques. We encourage you to explore more about milling processes and practice using these equations for better results.FAQs

Certainly! Here Are Five Questions Related To Milling Cutter Cutting Load Equations:Sure! Here are five questions about milling cutter cutting load equations: 1. What is a milling cutter? A milling cutter is a tool we use to cut shapes into materials like metal or wood. 2. Why do we need to calculate cutting load? We need to know the cutting load to make sure our tools work safely and last longer. 3. How does the cutting load affect the machine? If the cutting load is too high, it can break the machine or the cutter. 4. What factors change cutting load? Things like the material being cut, how fast you cut, and the tool’s shape can change the cutting load. 5. How do we measure cutting load? We measure cutting load using special tools that show us how much force is being used while cutting.

Sure! Just give me the question you’d like me to answer, and I’ll help you out with a simple response.

What Factors Influence The Cutting Load Experienced By A Milling Cutter During The Machining Process?The cutting load on a milling cutter depends on several factors. First, the type of material being cut affects how hard the cutter has to work. Second, the speed at which we move the cutter can change the load. Also, the depth of the cut is important; deeper cuts make it harder for the cutter. Finally, the sharpness of the cutter matters, too; a sharp cutter makes it easier to cut through materials.

Sure! Please give me the question you’d like me to answer.

How Can The Cutting Load Equations Be Modified For Different Materials Being Machined With A Milling Cutter?You can change the cutting load equations for different materials by adjusting a few key parts. First, you need to know how hard or soft the material is. For example, cutting wood needs less force than cutting metal. You can also change the speed of the cutter and the sharpness of its edge. Lastly, using coolant can help, too, since it keeps everything cool and makes cutting easier.

Sure! Just give me the question you want answered, and I’ll help you with it in a simple way.

What Is The Significance Of The Chip Load Parameter In Calculating The Cutting Load For Milling Operations?The chip load is important because it tells us how much material we cut with each blade on the tool. If the chip load is right, the tool works well and lasts longer. A good chip load means we can cut faster and smoother. Too much or too little can break the tool or make a mess. So, we pay attention to chip load to keep everything running nicely.

Sure! Please provide the question you would like me to answer.

How Do Changes In Feed Rate And Spindle Speed Affect The Cutting Load On A Milling Cutter According To Established Equations?When we change the feed rate, we change how fast the material moves into the cutter. A higher feed rate means more material is cut at once, which increases the cutting load. Spindle speed is how fast the cutter spins. If we increase the spindle speed, it can lower the cutting load because the cutter is slicing through the material faster. So, both feed rate and spindle speed can change how hard the cutter works!

Of course! Please provide the question you want me to answer.

Can You Explain The Differences Between Axial And Radial Cutting Loads And How Each Is Represented In Milling Cutter Cutting Load Equations?Axial cutting loads are forces that push down on the cutter, while radial cutting loads push sideways. In milling, we use both types of loads to show how the cutter works. Axial loads help us understand how deep the cutter goes, and radial loads show how wide it cuts. We can use special equations to calculate these loads and make sure machines work safely and well.