Have you ever wondered how hot a milling cutter can get while working? It’s a question many people ask when they think about metal cutting. Milling cutters are wonderful tools in factories. They can shape and cut metal into amazing designs.

But did you know that these tools have a limit for cutting temperature? If they get too hot, they can break or become less effective. Keeping the right temperature is important for success. Imagine trying to bake cookies but leaving them in the oven for too long — they burn! Similarly, milling cutters need careful temperature management.

In this article, we will explore milling cutter cutting temperature limits. You will learn how heat affects performance and why it matters. By understanding this, you can make better decisions next time you use one of these tools. Are you excited to find out more? Let’s dive in!

Milling Cutter Cutting Temperature Limits: Essential Insights

Milling Cutter Cutting Temperature Limits

Milling cutters create heat while cutting materials. But did you know there’s a limit to that temperature? If the cutter gets too hot, it can wear down quickly and even break! Understanding the ideal cutting temperature is essential for better tool life and performance. Regularly monitoring this heat can improve efficiency. Always remember, a cooler cutter means a happier workshop, right? Take care of your tools, and they’ll take care of you!Understanding Cutting Temperature in Milling

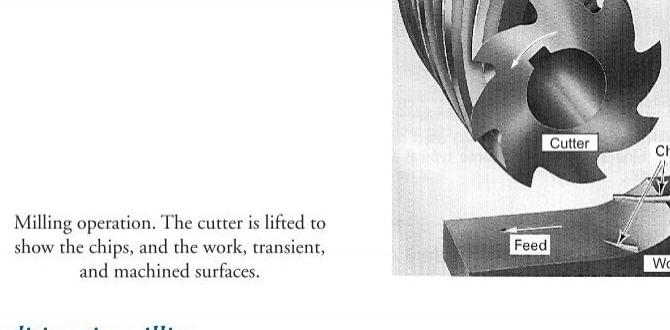

Definition of cutting temperature and its importance in milling operations. Factors influencing cutting temperature during milling processes.Cutting temperature is the heat generated during milling, a crucial process in shaping materials. Its importance lies in preserving tool life and achieving better results. High temperatures can damage both the cutting tool and the workpiece. Key factors influencing cutting temperature include:

- Material type

- Cutting speed

- Feed rate

- Cutting tool geometry

- Lubrication methods

Understanding these factors helps in controlling cutting temperatures for effective milling operations.

What are cutting temperature limits in milling?

Cutting temperature limits in milling refer to the maximum heat a tool can withstand without damage. Staying below these limits is key to tool life and performance. Maintaining lower temperatures reduces wear and tear.

The Effects of High Cutting Temperatures

Impact of elevated temperatures on tool wear and lifespan. Consequences for workpiece quality and machining accuracy.High cutting temperatures can really affect tools and machines. They cause tool wear, which means the tools get damaged faster. This leads to a shorter lifespan for the tools. Also, high heat can harm the quality of the workpiece. It may not come out as perfectly as planned. If the heat is too much, it can change the shape and size of what you are making.

- Increased tool wear leads to more frequent replacements.

- Poor workpiece quality can result in extra costs.

- Machining accuracy is reduced, leading to product failure.

Keeping cutting temperatures within limits is crucial for better performance. It saves money and time in the long run.

How does cutting temperature affect machining?

High cutting temperatures impact tool life and product quality. They cause tools to wear out quickly and can lead to defects in the finished piece.

Identifying Optimal Temperature Limits for Milling Cutters

Recommended temperature thresholds for various materials. Tools and techniques for measuring cutting temperature.Finding the right temperature for milling cutters is important. Different materials have different recommended limits. For example, steel should stay under 170°C, while aluminum is safe up to 200°C. Monitoring these temperatures helps to prevent damage and improve tool life.

To measure cutting temperature, you can use:

- Infrared thermometers – quick and easy to use

- Thermocouples – precise and reliable

- Thermal imaging cameras – provide clear visuals of heat distribution

By using the right tools, you can keep your milling process efficient and effective.

What is the optimal temperature limit for milling cutters?

The optimal temperature limit varies, but keeping steel under 170°C and aluminum below 200°C is key for better performance.

Material Selection for Milling Cutters and Its Impact on Temperature Resistance

Comparison of materials used in milling cutters and their thermal properties. How material selection can influence cutting temperature and performance.Choosing the right material for milling cutters is very important. Different materials have different heat-resistant properties. For example, high-speed steel (HSS) may work well for softer materials but can heat up quickly. Tungsten carbide, on the other hand, stays cooler during cutting. Selecting the right material affects cutting temperature and overall performance. To make the best choice, consider the material and how it handles heat.

How does material choice affect milling cutter temperature limits?

The choice of material can greatly influence cutting temperatures. High-speed steel (HSS) has lower thermal resistance, while materials like tungsten carbide handle heat much better. This means less wear and longer-lasting performance!

Key Material Properties

- High-Speed Steel (HSS): Good for low temperatures but wears faster.

- Tungsten Carbide: Excellent heat resistance and durable.

- Ceramics: Best for high-speed cutting but brittle.

Best Practices for Minimizing Cutting Temperature

Strategies for tool path optimization to reduce heat generation. Importance of feed rate and spindle speed adjustments.To keep cutting temperatures low, it’s key to optimize your tool path. A smart path design helps reduce heat. Adjusting the feed rate and spindle speed also matters. Using a slower feed rate helps lessen friction and cools the cutter.

- Make sure the tool path is smooth.

- Use a higher spindle speed for better cutting.

- Experiment with feed rates to find the best fit.

These changes not only help your tools last longer but also improve your work quality. Remember, less heat means better cutting!

How can I lower cutting temperatures?

To lower cutting temperatures, try optimizing your tool path, adjusting feed rates, and increasing spindle speed. Each change helps reduce heat and improves performance, making your work easier and safer.

Case Studies: Real-World Applications of Temperature Management in Milling

Examples of successful temperature management in industrial milling scenarios. Lessons learned from case studies to apply in future milling processes.Successful temperature management in industrial milling shows us its real value. For example, a car parts manufacturer reduced heat by using better cooling fluids. This kept the milling cutter sharp and saved time. Another company improved their cutting speed without overheating. These cases teach future milling processes valuable lessons:

- Use cooling fluids for better results.

- Monitor temperature closely to avoid damage.

- Adjust speeds to keep tools sharp.

By applying these lessons, milling operations can run smoother and more efficiently.

How can temperature management improve milling processes?

Temperature management can enhance tool life, reduce downtime, and improve product quality in milling processes.

Future Trends in Milling Technologies and Temperature Management

Innovations on the horizon, including smart tools and AI in milling. Predictions for how future technologies will address cutting temperature challenges.Exciting technologies are coming to milling. Smart tools and artificial intelligence will change how we work. These innovations will help manage cutting temperature better. Here are some trends to watch:

- Advanced sensors to monitor heat.

- AI predicting temperature spikes.

- New materials to lower heat buildup.

Experts believe future tools will improve efficiency. This means safer and faster cutting processes. Imagine machines that think ahead!

What are future milling technologies?

Future milling technologies will include smart tools, improved sensors, and AI. These will make managing cutting temperatures easier and more effective.

Conclusion

In conclusion, understanding milling cutter cutting temperature limits is crucial. High temperatures can damage tools and affect quality. We should monitor heat during milling to ensure better performance. You can improve your projects by exploring cooling methods and materials. For deeper insights, consider reading more about milling techniques. Taking action now will help you achieve better results in your work!FAQs

Certainly! Here Are Five Questions Related To Milling Cutter Cutting Temperature Limits:Sure! When we use milling cutters, they can get hot while cutting. High temperatures can make the cutter wear out faster. To keep them cool, we can use oil or water. It’s also important to choose the right speed for cutting. This way, we can help the cutter last longer!

Sure! Just ask your question, and I’ll be happy to help you with a clear answer.

What Are The Typical Cutting Temperature Limits For Different Types Of Milling Cutters (E.G., High-Speed Steel, Carbide, Ceramic)?Milling cutters are tools that help us shape materials. High-speed steel cutters can handle temperatures up to about 600°F (315°C). Carbide cutters are tougher and can work at around 1,000°F (538°C). Ceramic cutters can go even higher, up to about 2,000°F (1,093°C). Each type of cutter is good for different jobs based on how hot it can get!

How Does Cutting Speed Influence The Temperature Generated During The Milling Process?When you cut faster during milling, the tool rubs against the material more quickly. This extra rubbing creates more heat. So, higher speeds mean higher temperatures. If it gets too hot, it can damage the tool or the material. You need to pick the right speed to keep everything cool and working well.

What Are The Potential Effects Of Exceeding The Temperature Limits On Milling Cutter Performance And Workpiece Quality?If we let the milling cutter get too hot, it can break or wear down faster. This affects how well it cuts, making it less sharp over time. When the cutter isn’t working well, the pieces we make can have rough edges or be the wrong shape. So, keeping the temperature right helps us get better cuts and smoother pieces.

What Cooling Methods Can Be Employed To Manage Cutting Temperatures And Enhance Milling Cutter Longevity?To keep cutting tools cool while they work, we can use different cooling methods. You can pour cool liquids, like water or oil, on the tool as it cuts. This is called flood cooling. We can also use air blasts to blow cool air on the tool. These methods help the tool last longer and work better.

How Do Tool Geometry And Material Selection Impact The Thermal Behavior Of Milling Cutters During Operation?The shape and design of milling cutters, called tool geometry, affect how heat is made. Different materials help with heat control. If a cutter is sharp and made of strong stuff, it gets less hot. This helps the tool last longer and work better. Good choices keep everything cool and running smoothly.