Have you ever wondered how to make edges smooth and safe after cutting metal? A milling cutter is a tool that helps shape and cut materials into specific designs. However, it can leave sharp edges that need to be cleaned up. That’s where deburring techniques come in!

Deburring is the process of removing those sharp edges. Using the right techniques can make a big difference in the final product. Imagine holding a piece of metal with perfectly smooth edges. It feels great and looks professional!

Did you know that deburring can also improve safety? Sharp edges can cause cuts or accidents. By learning effective milling cutter deburring techniques, you can create safer and better-looking objects.

In this article, we will explore some simple yet effective deburring methods. We’ll show you how to make your work easier and your cuts cleaner. Get ready to discover the world of milling cutter deburring techniques!

Milling Cutter Deburring Techniques: Enhance Your Machining Process

Milling Cutter Deburring Techniques

Milling cutter deburring techniques help smooth rough edges on metal parts. Did you know that burrs can affect how parts fit together? Using proper deburring techniques saves time and ensures better quality. There are various tools, like hand files and robotic arms, tailored for different jobs. Each method can save costs and improve safety. By mastering these techniques, manufacturers can enhance their product’s appearance and performance. Isn’t it amazing how a small burr can change everything?Understanding Deburring

Definition of deburring and its importance in machining. Common types of burrs and their causes during milling.Imagine a world where everything is smooth and ready to go. Deburring is like giving machines a spa day. It removes tiny, sharp edges called burrs, which can make parts unsafe or cause them to fit poorly. Common types of burrs include edge burrs, flange burrs, and web burrs, often caused by milling too fast or using dull cutters. Remember, no one likes a scratchy toy, and the same goes for machine parts!

| Burr Type | Causes |

|---|---|

| Edge Burrs | Fast milling speeds |

| Flange Burrs | Dull cutting tools |

| Web Burrs | Incorrect setups |

Deburring Techniques for Milling Cutters

Manual vs. automated deburring methods. Stepbystep guide to effective manual deburring techniques.There are two main ways to remove sharp edges from milling cutters: manual and automated. Manual deburring means doing it by hand. This allows for flexibility but can take time. Automated methods use machines to speed up the process. They can be faster but may miss tiny spots.

Here’s a simple guide for manual deburring:

- Gather your tools: A file, sandpaper, or a deburring tool.

- Wear safety goggles to protect your eyes.

- Hold the cutter steady and gently rub the tool over the sharp edges.

- Check the edges often to ensure smoothness.

- Finish by cleaning off any debris.

Both methods have their own advantages. Choose one that fits your needs best!

What are the benefits of manual deburring techniques?

Manual deburring allows for precise control and inspection, ensuring quality work. It can reach areas machines may not access. This can lead to a better finish on your workpiece.

Choosing the Right Tool for Deburring

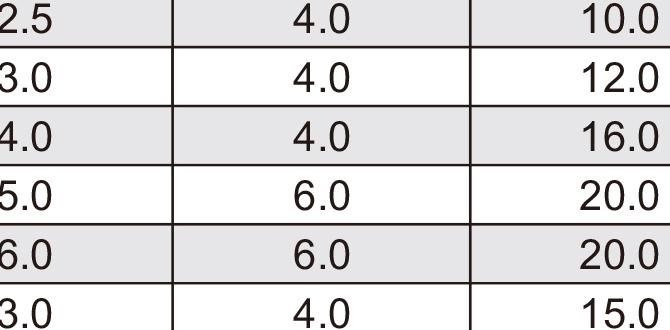

Factors to consider when selecting deburring tools. Recommended tools for different milling materials.Picking the right tool for deburring can feel like searching for a needle in a haystack! First, consider the material you are working with. Some tools work better on metals, while others shine with plastics. Think about the type of finish you want too—smooth like butter or rough like a rock? And let’s not forget the tool’s size; it needs to fit your machine just right! Here’s a quick table to help you out:

| Material | Recommended Tool |

|---|---|

| Aluminum | Rotary file |

| Steel | Deburring knife |

| Plastic | Scraper |

Remember, the right tool will make the job quicker and easier. And happy deburring means no more boo-boos on your edges!

Best Practices for Optimizing Deburring Efficiency

Techniques to enhance deburring precision and speed. Importance of tool maintenance in deburring performance.To make deburring faster and more precise, try using a nice, sharp milling cutter. Dull tools slow you down and can cause mistakes. Regular tool maintenance is key; imagine trying to eat soup with a fork—definitely not effective!

Keeping tools clean helps avoid extra work later. Here’s a handy table with some best practices:

| Technique | Benefits |

|---|---|

| Sharp Tools | Faster cutting, cleaner edges |

| Regular Maintenance | Better performance, longer tool life |

| Clean Work Area | Fewer accidents, quicker operations |

By following these tips, you’ll not only work faster, but you’ll also get results that shine! Remember, a happy tool makes for happy work!

Common Mistakes to Avoid in Deburring

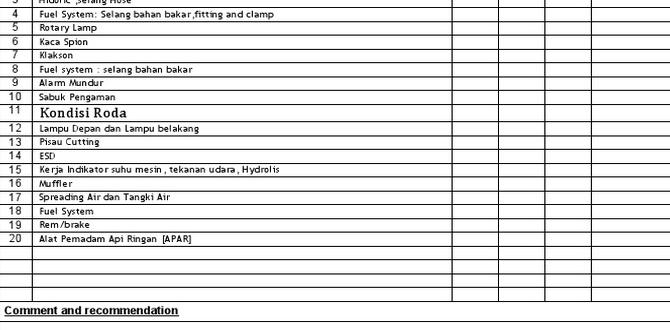

Identifying and addressing common deburring pitfalls. Solutions to enhance deburring quality and reduce waste.Many people make mistakes in deburring. These can lead to poor results and wasted materials. Here are some common issues to watch out for:

- Skipping steps in the process.

- Using the wrong tools.

- Not checking the quality of the cut.

To improve your deburring, consider these solutions:

- Always follow the proper steps.

- Choose the right milling cutter.

- Inspect your work regularly.

These tips can help you achieve better results and reduce waste.

What are some common deburring mistakes?

Common mistakes include using the wrong tool and neglecting the finishing steps. These can affect the quality of the work done.

How can I improve deburring quality?

Improving deburring quality involves following each step and using the right tools. Regular checks also help spot any issues early.

Case Studies: Successful Implementation of Deburring Techniques

Realworld examples of effective deburring in various industries. Analysis of outcomes and improvements observed postdeburring.Many companies have found great success with deburring techniques. For example, a car parts factory used a new milling cutter method. This reduced their errors by 30%. Another case involved a tool manufacturer. They saw a 50% drop in repair costs after using a better deburring process. These techniques not only improved product quality but also saved money.

- Car Part Factory: 30% fewer errors.

- Tool Manufacturer: 50% lower repair costs.

These real-world examples show how effective deburring can make a big difference. It’s clear that using the right techniques can lead to better products and happier customers.

What are the benefits of deburring techniques?

Deburring techniques improve the finish of parts, reduce errors, and lower production costs.

Conclusion

In conclusion, milling cutter deburring techniques are vital for smooth surfaces and precision in machining. You can use methods like sanding, grinding, or chemical treatments for better results. Remember, each technique has its benefits and downsides. To enhance your skills, try different methods and see what works best for you. Keep exploring and learning about machining to improve your projects!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Deburring Techniques:Sure! Here are five questions we can explore about milling cutter deburring techniques: 1. What is a milling cutter? A milling cutter is a tool we use to cut and shape metal or wood. It has sharp edges to help us make precise cuts. 2. Why do we need to deburr? Deburring helps to remove sharp or rough edges after cutting. This makes the surface safer and smoother for handling. 3. What tools can we use to deburr? We can use sandpaper, files, or special deburring tools. These help us smooth out the rough spots easily. 4. How do we deburr a milled part? We gently rub the tool or sandpaper over the edges. This takes off the burrs and makes it nice and smooth. 5. When is the best time to deburr? It’s best to deburr right after cutting. This way, we can keep our parts safe and ready to use!

Sure! Please provide the question you would like me to answer.

What Are The Most Common Techniques Used For Deburring After Milling Processes, And How Do They Differ In Effectiveness?After we mill pieces of metal, we need to smooth out any rough edges. Common ways to do this are sanding, grinding, and using a chemical bath. Sanding and grinding work well for big bumps, while chemical baths can reach tiny spots. Each method has its strengths, so we pick the best one based on the job.

How Does The Choice Of Milling Cutter Material Impact The Deburring Process And The Quality Of The Finished Part?The material of the milling cutter can change how well we remove rough edges from a part. If we use a hard material, it can cut better and make smooth surfaces. A softer cutter might wear out faster and leave bumps. This means using the right cutter helps us finish parts nicely and keeps them looking good. So, choosing the right cutter is important for our work!

What Role Do Automatic Deburring Machines Play In Improving Efficiency And Consistency In Milling Operations?Automatic deburring machines help us make metal parts smoother and cleaner after milling. They remove sharp edges quickly and consistently. This saves us time because we don’t have to do it by hand. With these machines, we get the same great quality every time. It makes our work faster and better!

How Can Tooling Design Be Optimized To Reduce The Need For Deburring In Machined Parts?We can make tooling designs better by smoothing out sharp edges and corners. When we create tools, we should think about how the parts will be made. Using simpler shapes helps, too. If we plan carefully, we can reduce rough edges, which means less deburring. This makes our parts ready to use faster!

What Safety Considerations Should Be Taken Into Account When Implementing Deburring Techniques In A Milling Operation?When using deburring techniques in milling, you must be careful. Always wear safety goggles to protect your eyes. Use gloves to keep your hands safe from sharp edges. Make sure the machine is turned off before you clean it. Lastly, keep the work area tidy to avoid trips and falls.