When it comes to tools in a workshop, milling cutters are essential. Have you ever thought about the difference between a double-ended and a single-ended milling cutter? These two tools each have special features and uses.

Imagine you’re trying to shape a piece of metal. Using the right cutter can make your job easier and faster. But which one is better? A single-ended milling cutter has one cutting end. This makes it great for some tasks. In contrast, a double-ended milling cutter has two ends. That means you can use it for more jobs without changing tools.

A fun fact is that many people don’t know which one to choose. Some think that double-ended cutters are always the best. But that’s not the case! Each style can be perfect, depending on what you need. This article will explore the strengths and weaknesses of both types. So, let’s dive in and discover which milling cutter could be your new favorite tool!

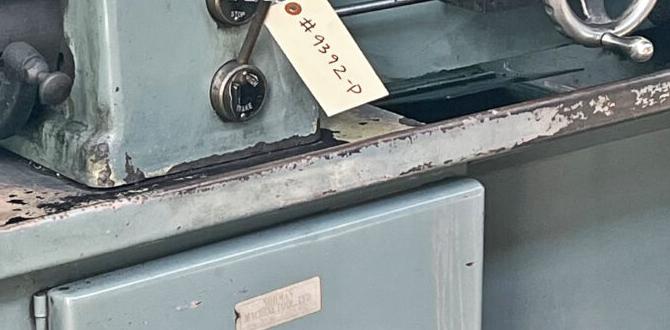

Milling Cutter Double-Ended Vs Single-Ended: Key Differences Explained Milling Cutters Are Essential Tools In The Machining World, Enabling The Precise Shaping And Cutting Of Materials Like Metals And Plastics. When It Comes To Choosing The Right Milling Cutter For Your Project, Understanding The Differences Between Double-Ended And Single-Ended Cutters Is Crucial. This Guide Will Explore These Differences, Their Applications, And Which Option Might Be Best For Your Specific Needs. What Is A Milling Cutter? A Milling Cutter Is A Rotary Tool Used In Milling Machines To Remove Material From A Workpiece. They Come In Various Shapes, Sizes, And Types, Each Designed For Specific Applications. Key Distinctions Must Be Made Between Double-Ended And Single-Ended Milling Cutters, As They Offer Different Advantages And Potential Uses. Double-Ended Milling Cutters Double-Ended Milling Cutters Have Cutting Edges On Both Ends Of The Tool. This Design Allows For Increased Efficiency And Longevity. Here Are Some Key Points Regarding Double-Ended Milling Cutters: – **Versatility:** With Cutting Capabilities At Both Ends, These Tools Can Be Used For Various Applications, Saving Time On Tool Changes. – **Cost-Effectiveness:** Since Both Ends Can Be Utilized, They Offer More Cutting Life, Reducing The Frequency Of Replacements. – **Common Uses:** Often Utilized In Industries Where Materials Are Moved Frequently, Double-Ended Cutters Are Popular For Batch Machining And Multi-Sided Operations. Single-Ended Milling Cutters In Contrast, Single-Ended Milling Cutters Have A Cutting Edge At Only One End. While They May Seem Less Efficient At First Glance, They Have Their Own Benefits: – **Simplicity:** Single-Ended Cutters Are Generally Easier To Manufacture, Leading To Less Complexity In Design And Often Lower Costs. – **Specialization:** For Certain Tasks, Such As Intricate Cuts Or Specific Geometries, Single-Ended Cutters May Provide Improved Performance And Precision. – **Common Uses:** These Cutters Are Typically Used In Applications Requiring Fine Detailing Or Precision Work In Softer Materials. Choosing Between Double-Ended And Single-Ended The Choice Between Double-Ended And Single-Ended Milling Cutters Largely Depends On The Specific Requirements Of Your Project: 1. **Consider The Type Of Material:** Some Materials May Be Better Suited To One Type Of Cutter Over The Other. 2. **Evaluate Your Machining Needs:** If You Require Extensive Cutting And Faster Tool Changes, Double-Ended May Be The Way To Go. For Tasks Demanding Precision, A Single-Ended Cutter May Serve Better. 3. **Cost Considerations:** Take Into Account The Initial Investment And Potential Savings Over Time With Longer-Lasting Double-Ended Options. Conclusion Both Double-Ended And Single-Ended Milling Cutters Serve Unique Purposes Within Various Manufacturing And Machining Environments. Understanding Their Distinct Characteristics Helps In Making Informed Decisions That Align With Project Needs And Efficiency Goals. By Weighing The Benefits Of Each Type, You Can Choose The Most Appropriate Milling Cutter For Your Operations, Ensuring Optimal Performance And Productivity.

Milling Cutter: Double-Ended vs Single-Ended

Milling cutters come in two main types: double-ended and single-ended. Double-ended cutters have cutting edges on both ends, making them efficient for longer tasks. This saves time since you can flip the cutter instead of changing it. Single-ended cutters only have one cutting edge. They are often easier to handle and provide more precise cuts. Choosing the right type can make a big difference in your machining results. Which one will you try for your next project?Understanding Milling Cutters

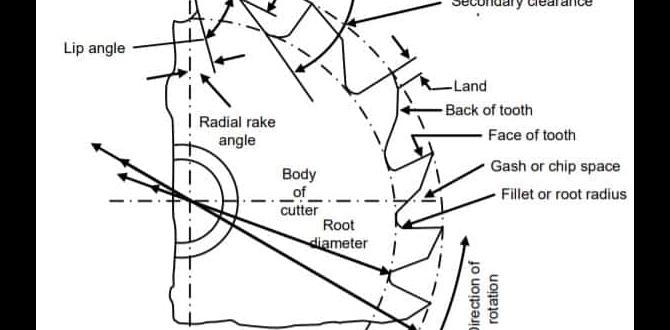

Definition and purpose of milling cutters. Key components and types of milling cutters.Milling cutters are tools used in machines to shape and cut materials. They help create parts for machines, cars, and tools. There are many types of milling cutters, each designed for specific tasks. Here are key components:

- Cutting edges: The sharp parts that do the cutting.

- Body: The main part that holds everything together.

- Shank: The part that connects the cutter to the machine.

Common types include:

- Face mills: Ideal for flat surfaces.

- End mills: Great for detailed cuts.

- Slot drills: Perfect for making narrow grooves.

Understanding these tools helps ensure better cuts and shapes in projects.

What are double-ended and single-ended milling cutters?

Double-ended cutters have two working ends, which allows you to use them longer. They are great for saving time and money. Single-ended cutters have only one end, making them simpler but needing replacement more often.

Double-Ended Milling Cutters

Features and design of doubleended milling cutters. Advantages of using doubleended milling cutters.Double-ended milling cutters are like the Swiss Army knives of the machining world. They have cutting edges on both ends, allowing them to work double duty. This means less time changing tools and more time creating! They are designed for efficient cutting and saving precious resources. Plus, you can be the hero of your workshop by cutting costs on tool replacements.

| Features | Advantages |

|---|---|

| Two cutting edges on each tool | Increased efficiency with less downtime |

| Generally more durable | Cost-effective since they last longer |

| Flexible in various machining tasks | Quicker transitions between jobs |

Using double-ended milling cutters can give your projects a boost. Remember, two ends are better than one—kind of like having two ice cream cones on a hot day!

Single-Ended Milling Cutters

Features and design of singleended milling cutters. Advantages of using singleended milling cutters.Single-ended milling cutters are like pizza with all your favorite toppings on one side. They have a blade on one end, making them perfect for specific tasks. These tools are designed for precision and control, cutting smoothly in one direction. The biggest advantage? They are easy to use and great for creating accurate shapes! Plus, because they focus the cutting action on one side, they often last longer than their double-ended buddies. Who knew cutting could be this fun?

| Features | Advantages |

|---|---|

| Simple design | Easy to control |

| One-sided blade | Lasts longer |

| Lightweight | Great for precise cuts |

Comparative Analysis: Double-Ended vs Single-Ended

Performance differences in various applications. Costefficiency and tool life comparison.Choosing between double-ended and single-ended milling cutters can feel like picking between two tempting candies. Each has its perks! Double-ended cutters excel in their ability to perform longer tasks without frequent changes. This makes them great for heavy work. However, they often come with a slightly higher price tag. Single-ended cutters, on the other hand, are budget-friendly and perfect for smaller jobs. They might wear out faster, but their cost efficiency makes up for it.

| Feature | Double-Ended Cutter | Single-Ended Cutter |

|---|---|---|

| Performance | Longer cutting tasks | Ideal for smaller tasks |

| Cost | Higher pricing | More budget-friendly |

| Tool Life | Generally longer | May wear out sooner |

Applications and Use Cases

Common industries using each type of milling cutter. Specific tasks suited for doubleended vs singleended cutters.Different types of milling cutters play key roles in various industries. For example, double-ended cutters are famous in manufacturing and metalworking. They work well for tasks needing precision on both ends. Single-ended cutters shine in woodworking and plastic machining. They are perfect for detailed jobs and can easily shape materials. Here’s a quick glance at their applications:

| Type | Common Industries | Specific Tasks |

|---|---|---|

| Double-Ended | Manufacturing, Metalworking | Surface finishing, Deep cuts |

| Single-Ended | Woodworking, Plastics | Detail shaping, Trimming |

Choosing the right cutter can be a real *cut* above the rest!

Maintenance and Care

Best practices for maintaining doubleended milling cutters. Best practices for maintaining singleended milling cutters.Caring for milling cutters is essential for long-lasting performance. Double-ended milling cutters should be cleaned after each use. Store them in a dry place to prevent rust. Check for wear regularly to ensure they cut effectively. For single-ended milling cutters, always sharpen them before they become dull. Use protective caps when storing. A good practice is to examine them before each project to spot any damage early.

How can I maintain milling cutters effectively?

Keep them clean, sharp, and stored properly. Regular checks help spot problems before they worsen.Choosing the Right Milling Cutter for Your Project

Factors to consider when selecting a cutter type. Recommendations for specific machining needs and materials.Choosing the right milling cutter is very important for your project. You should think about a few things before making a decision:

- Project Type: Different projects need different cutters. Know if you are making big parts or small details.

- Material: Consider the material you will cut. Hard metals need stronger cutters.

- Cutter Length: Double-ended cutters may be better for longer jobs, while single-ended are great for simple tasks.

For soft materials, a single-ended cutter is often enough. For tough materials, you might want to go with a double-ended one. This way, you get the best results!

What should I know about milling cutters?

A milling cutter can change how your work turns out. Choosing the right type helps you work faster and better.

Expert Opinions and Insights

Industry expert opinions on the best practices for milling. Interviews or quotes from experienced machinists.Industry experts agree that choosing the right milling cutter can greatly enhance your work. According to expert machinist Linda Clarke, “Always pick the best tool for the job. It’s like choosing a pencil to draw!” She emphasizes that double-ended cutters can save time, while single-ended ones often offer more accuracy. Tool longevity is also a concern; some pros say, “Why wear out one side when you can switch it up?” Here’s a quick comparison for better insight:

| Feature | Single-Ended | Double-Ended |

|---|---|---|

| Usage | Better for precision tasks | Ideal for general milling |

| Longevity | Can wear out quickly | More versatile, doubles the life |

| Cost | Often cheaper | Usually higher initial investment |

Always remember to pick your milling cutters wisely!

Conclusion

In summary, double-ended milling cutters have cutting edges on both ends, allowing for longer use and more efficiency. Single-ended cutters are easier to manage but need to be replaced more often. You can choose based on your project needs. We encourage you to explore more about these tools and try them out for your next machining project!FAQs

Sure! Here Are Five Related Questions On The Topic Of Double-Ended Vs Single-Ended Milling Cutters:Sure! A double-ended milling cutter has two cutting ends. This means it can cut from both sides. A single-ended milling cutter has only one cutting end. Each type is used for different jobs when we make things from metal or wood. Using the right cutter helps us finish tasks quicker and better!

Sure! Please provide me with the question you want answered.

What Are The Primary Differences In Design And Functionality Between Double-Ended And Single-Ended Milling Cutters?Double-ended milling cutters have cutting edges on both ends, while single-ended ones only have one. This means you can use double-ended cutters longer before they need replacing. They also help you save time since you can switch ends instead of changing tools. In simple terms, double-ended cutters are more efficient for some tasks.

In What Applications Would A Double-Ended Milling Cutter Be Preferred Over A Single-Ended Cutter?You would prefer a double-ended milling cutter when you need to work quickly. It has cutting edges on both ends, so when one side gets dull, you can flip it over. This saves time because you don’t have to change the tool as often. It’s useful for making things like metal parts or wood shapes where we need efficiency.

How Does The Cost-Effectiveness Of Double-Ended Milling Cutters Compare To Single-Ended Cutters In Industrial Settings?Double-ended milling cutters have cutting edges on both ends. This means they can cut longer before needing a change. You save money by using them longer. Single-ended cutters wear out faster and need more replacements. So, double-ended cutters are often more cost-effective in factories.

What Factors Should Be Considered When Choosing Between A Double-Ended And Single-Ended Milling Cutter For A Specific Machining Task?When choosing a milling cutter, think about what you need to do. A double-ended cutter has cutting teeth on both ends, so you can use it longer before it wears out. If you need to make quick cuts and want to change tools less often, that could be a good choice. On the other hand, a single-ended cutter might work better for smaller, precise tasks. You also need to consider the type of material you are working with and the speed you need.

How Do Maintenance And Tool Life Differ Between Double-Ended And Single-Ended Milling Cutters?Double-ended milling cutters have cutting edges at both ends, while single-ended ones have only one. This means double-ended cutters last longer because you can flip them to use the other side. For maintenance, double-ended cutters might need less frequent sharpening since you can use both ends. In contrast, single-ended cutters need more care and can wear out faster. So, if you want something that lasts longer, consider using double-ended milling cutters!