Imagine trying to make something perfect, but the tool you use keeps breaking. That can be really frustrating, right? In the world of manufacturing, that is a common issue. Milling cutter edge chipping is a problem that many face. It can ruin your work and waste precious time.

But what if I told you that there are ways to prevent this chipping? Yes, there are smart techniques that can help keep the edges of your milling cutters strong and sharp. Knowing how to protect your tools means you can focus on creating great things.

Did you know that even small changes in how you use a milling cutter can make a big difference? The right speed and feed can extend the life of your tools. With a few simple tips, you can lessen edge chipping and improve your results.

Let’s explore these techniques together. Your tools deserve the best care, and preventing edge chipping is a great place to start!

Milling Cutter Edge Chipping Prevention Techniques And Tips

Milling Cutter Edge Chipping Prevention

When milling, edge chipping can ruin your tools. Did you know that using the right speeds and feeds can make a difference? Keeping your milling cutter sharp also helps. You can prevent chipping by using the correct cutting fluid and maintaining proper tool setup. Imagine constantly replacing cutters; it’s not only expensive but also time-consuming. By following these tips, you can extend the life of your tools and improve your work efficiency!Understanding Edge Chipping in Milling Cutters

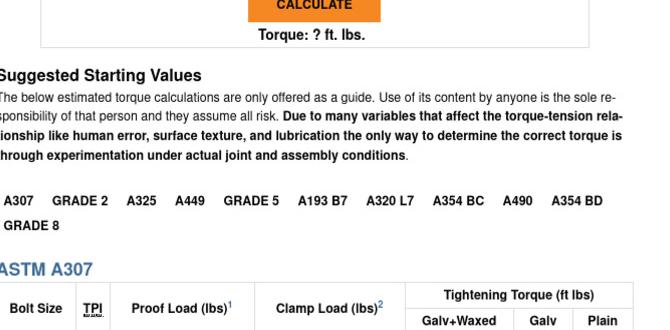

Definition and significance of edge chipping. Causes of edge chipping in milling operations.Edge chipping is when tiny bits break off the edges of a milling cutter. This is a big deal because it can ruin your work and lead to extra costs. Common causes include using dull tools, poor material contact, and incorrect speeds. Even accidental bumps can make your cutter cry out, “Ouch!” Here’s a quick look at some causes:

| Causes of Edge Chipping | Description |

|---|---|

| Dull Tools | They struggle to cut smoothly, leading to chips. |

| Incorrect Speeds | Too fast or slow can stress the edge. |

| Material Properties | Harder materials often create more chipping. |

By understanding these factors, you can keep your milling cutters happy and avoid frustrating repairs.

Coating Technologies to Enhance Tool Durability

Description of various coatings used on milling cutters. How coatings contribute to edge chipping prevention.Coating technologies help make milling cutters last longer. Different coatings protect the cutting edges from wear and chipping. Here are a few common types:

- Titanium Nitride (TiN) – This coating is hard and reduces friction.

- Titanium Carbonitride (TiCN) – It adds toughness and is good for heavy loads.

- Diamond-like Carbon (DLC) – This coating is super smooth and very durable.

These coatings work like armor, stopping edge chipping and improving performance. They help tools cut better and last longer. In fact, tools with coatings can last up to 5 times longer than uncoated ones!

How do coatings help prevent edge chipping?

Coatings reduce friction and wear, protecting tools from damage. They help keep the edges sharp, which is key to avoiding chipping.

Optimal Milling Parameters for Edge Protection

Recommended cutting speeds and feeds. Influence of depth of cut on edge durability.Choosing the right settings for milling can protect your tools. Recommended cutting speeds are important. Use a speed that isn’t too fast or slow. For most materials, try a speed of 100-300 meters per minute. Feeding rates also matter. A good rate is around 0.1 to 0.5 millimeters per tooth.

The depth of cut affects edge durability. Thinner cuts reduce stress on edges. A depth of 1 to 3 millimeters is ideal for increased durability. Learning these tips helps keep your milling cutter sharp and ready for work.

What are the best cutting speeds for edge protection?

The best cutting speeds depend on the material but typically range between 100-300 meters per minute. This helps reduce wear on the edges.

Key Factors for Edge Protection

- Cutting speed: 100-300 meters/min

- Feeding rate: 0.1-0.5 mm/tooth

- Depth of cut: 1-3 mm

Tool Geometry Considerations

Impact of cutter design on edge chipping. Key geometric features that help minimize chipping.Choosing the right cutter design is like picking the perfect ice cream flavor—it can make all the difference! The shape and angle of a milling cutter greatly affect edge chipping. For example, a larger rake angle can help slice through materials smoothly, reducing the chance of damage. Key features include tight tolerances and sharp edges, which lead to cleaner cuts. So, next time you’re tooling up, remember: geometry isn’t just for math class; it’s crucial for keeping those cutting edges happy!

| Geometric Feature | Benefit for Edge Chipping |

|---|---|

| Rake Angle | Reduces cutting force, minimizes chipping |

| Clearances | Improves chip flow, reduces clogging |

| Edge Radius | Strengthens edges, less prone to wear |

Regular Maintenance and Inspection Practices

Importance of routine checks for wear and tear. Strategies for maintaining cutter edge integrity.Checking tools regularly is important. It helps spot any wear and tear before it becomes a big problem. A small chip can lead to bigger issues. Maintaining cutter edges keeps them sharp and effective. Here are some strategies:

- Check edges for small damages.

- Keep tools clean from debris.

- Sharpen edges as needed.

- Store tools properly to avoid damage.

Regular checks can save time and money. Remember, a little care goes a long way!

Why is routine maintenance important?

Routine maintenance prevents serious damage and enhances tool life. Regular checks stop minor wear from becoming a major issue.

What are some ways to maintain cutter edges?

- Inspect regularly for wear and chips.

- Clean tools after each use to avoid buildup.

- Sharp edges help machines work better.

- Store tools safely to keep them in good shape.

Implementing Advanced Machining Techniques

Techniques like dry machining and coolant usage. Benefits of modern CNC technologies in reducing edge chipping.Using advanced machining techniques can help keep cutting edges in shape. For instance, dry machining is like baking cookies without the messy flour—it keeps things cleaner! Coolants also play a big role, cooling down tools and reducing wear. Modern CNC technology is like having a superhero in the workshop. It precisely controls the machining process, which helps prevent edge chipping. Statistics show tools last longer with these methods. Say goodbye to those pesky chips!

| Technique | Benefit |

|---|---|

| Dry Machining | No coolant mess |

| Coolant Usage | Cool down the tools |

| CNC Technology | Precision and durability |

Case Studies and Real-World Applications

Examples of industries facing edge chipping issues. Successful strategies employed to mitigate chipping in practice.In many industries, edge chipping is that annoying sprinkles of confetti you didn’t ask for. The automotive and aerospace sectors often face this issue. It’s like trying to make a perfect cookie and ending up with crumbs! To combat this, companies have turned to tougher materials and smarter cutting speeds. They discovered that using coated milling cutters can really help. Think of it as putting a protective armor on your cookie—delicious and sturdy!

| Industry | Chipping Issue | Strategy Used |

|---|---|---|

| Automotive | High wear during production | Tougher materials |

| Aerospace | Precision needed | Smart cutting speeds |

Future Trends in Milling Cutter Technology

Innovations on the horizon for cutting tool design. Predictions for advancements in materials and coatings.Exciting changes await in cutting tool design! New innovations are popping up on the horizon. We might soon see super-strong materials that defy the usual wear and tear. Coatings could become so slick that they practically slide through metal. Imagine tools that laugh in the face of edge chipping! What’s even better? The future might just feature smarter tools that adjust their cutting style automatically. It’s like having a mini-expert in your toolbox!

| Innovation | Future Benefit |

|---|---|

| New Materials | Lower wear, longer life |

| Advanced Coatings | Less friction, better performance |

| Smart Technology | Adaptive cutting |

Conclusion

To prevent edge chipping on milling cutters, always use the right feed rates and tools. Check your materials for hardness. Keep your tools sharp and clean. Regular maintenance goes a long way. Remember, simple adjustments can save you time and money. For more tips, explore additional resources or ask a mentor. Stay curious and keep learning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Cutter Edge Chipping Prevention:Milling cutters are tools used to shape and cut materials. To prevent chipping, we can use the right speed and feed rate when cutting. Keeping the cutter sharp also helps. Make sure to clean the tool and check for wear regularly. If we take care of our tools, they will last longer!

Sure! Please share the question you would like me to answer.

What Are The Common Causes Of Edge Chipping In Milling Cutters, And How Can They Be Identified?Edge chipping on milling cutters happens for a few reasons. First, if the cutter is too dull, it can break bits off the edge. Second, using the wrong speed or pressure can cause damage. Third, hitting hard materials can chip the cutter too. You can spot edge chipping by looking for tiny cracks or rough areas on the cutting edge.

How Do Different Cutting Materials (E.G., Carbide, High-Speed Steel) Influence The Susceptibility Of Milling Cutters To Edge Chipping?Cutting materials like carbide and high-speed steel can change how easily milling cutters chip at their edges. Carbide is really hard and stays sharp longer, so it chips less. High-speed steel isn’t as hard, so it can chip more easily when cutting tough materials. The better the material, the less chance of chipping.

What Machining Parameters (Such As Feed Rate, Cutting Speed, And Depth Of Cut) Can Be Optimized To Reduce The Risk Of Chipping During Milling Operations?To reduce chipping while milling, we should pay attention to three important things: feed rate, cutting speed, and depth of cut. First, we can use a slower feed rate, which means moving the material more gently. Next, we should choose a cutting speed that is not too high, so the tool doesn’t break. Finally, keeping a shallow depth of cut helps the tool work better and reduces the chance of chipping. By adjusting these factors, we can make cutting smoother and safer.

How Can The Use Of Coatings And Surface Treatments On Milling Cutters Help In Preventing Edge Chipping?Coatings and surface treatments make milling cutters stronger. They create a tough layer on the cutter’s surface. This layer helps resist damage when cutting hard materials. With less damage, we prevent edge chipping. This means our tools last longer and work better!

What Maintenance Practices And Inspection Techniques Can Be Implemented To Extend The Lifespan Of Milling Cutters And Minimize Edge Chipping?To keep milling cutters in good shape, we should clean them regularly. After using them, wipe off any dirt or metal shavings. We can also check for tiny cracks or chips in the edges. If we find any damage, we should fix or replace them right away. Finally, storing them in a safe place will help prevent damage.