Have you ever wondered how to make your tools last longer? Imagine working on a project and realizing your milling cutter isn’t cutting as it should. That’s frustrating, right? One simple trick is to focus on milling cutter edge prep.

Proper edge preparation can change everything. It helps the cutter cut cleaner and stay sharp longer. This can save time and money. Think about how great it feels to complete a task without delays. Why wouldn’t you want that?

In this article, we will explore how edge prep can boost your tool’s longevity. We’ll share tips and tricks that anyone can use. By the end, you’ll be ready to keep your milling cutter in top shape!

Milling Cutter Edge Prep For Tool Longevity: Best Practices

Milling Cutter Edge Prep for Tool Longevity

Preparing the edges of milling cutters can significantly extend their life. Sharp, well-prepared edges reduce wear and improve cutting performance. Have you ever noticed how a dull knife struggles to cut? The same principle applies here. Proper edge prep not only enhances the quality of the cut but also leads to fewer tool changes. This means less downtime and more productivity on the shop floor. Isn’t it fascinating how a small detail can make such a big difference?Understanding Milling Cutters

Types of milling cutters and their uses. Importance of edge preparation in milling operations.Milling cutters come in many shapes and sizes. Each type serves a different purpose. Some common types include:

- End Mills – Great for making cavities and contours.

- Face Mills – Best for large, flat surfaces.

- Ball Nose Mills – Perfect for curved surfaces.

Edge preparation is very important for long-lasting tools. Good edge prep helps cutters last longer and cut smoother. Never overlook this step, as it can save time and money!

What are the types of milling cutters?

Milling cutters include end mills, face mills, and ball nose mills. Each is designed for specific tasks in machining. Understanding their uses makes milling easier and more efficient!

Importance of Edge Preparation

How edge preparation affects tool performance. The relationship between edge prep and tool life.Edge preparation is like giving your tools a nice haircut. A well-prepped edge lets cutting tools glide through materials smoothly. This minimizes friction, which means less heat and wear. Longer tool life? Yes, please! Studies show that a good edge prep can double your tool’s lifespan! Think of it as a spa day for your milling cutter—less stress equals better performance. So, keep that edge sharp and everyone will be happy, including your wallet!

| Edge Preparation | Tool Performance | Tool Life |

|---|---|---|

| Increases smoothness | Enhances cutting | Extends usage time |

| Reduces friction | Improves efficiency | Prevents damage |

| Minimizes heat | Aids in precision | Better value |

Methods of Edge Preparation

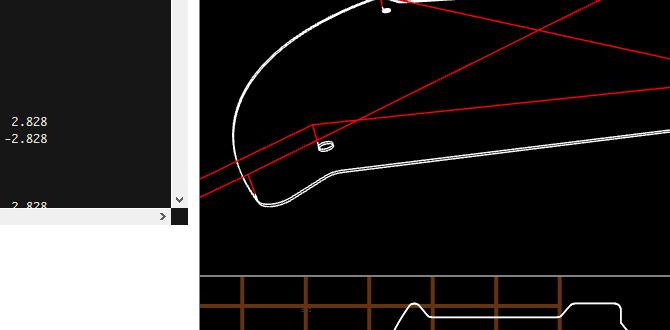

Traditional vs. advanced edge prepping techniques. Common tools and equipment used for edge preparation.Edge preparation for milling cutters can be done in two main ways: traditional and advanced. Traditional methods often use manual tools like files and grinders. They require skill and patience. Advanced techniques use machines that are faster and more precise. Common tools include:

- Diamond grinding wheels

- Electrolytic machines

- CNC machines

Choosing the right method and tools can increase the longevity of your milling cutters. Better edge prep leads to smoother cuts and less wear.

What are the common edge prep techniques?

Common techniques include manual sharpening, CNC grinding, and coating application. Each one helps improve tool performance.

Why is edge preparation important?

Edge preparation is key for tool life and cutting accuracy. Proper edges lead to cleaner work and reduced downtime.

Best Practices for Edge Preparation

Stepbystep guide to effectively prep milling cutter edges. Tips for maintaining consistency in edge preparation.Preparing the edges of a milling cutter is crucial for keeping it sharp and lasting long. Start by cleaning the edges with a soft cloth. Then, use a fine file to gently smooth out any rough spots. Always measure your angles with a protractor to keep things straight. Remember, consistency is key! Keep a log of your prep times. This helps track when the cutter needs work. A prepared cutter is a happy cutter—and, as they say, “a happy cutter makes happy chips!”

| Step | Action |

|---|---|

| 1 | Clean the edges |

| 2 | Smooth with a file |

| 3 | Check angles |

| 4 | Log preparation times |

By following these steps, you can ensure better performance and longer life for your milling cutter. Who knew that a little edge prep could lead to such big smiles—both for your cutter and your wallet!

Measuring and Assessing Edge Quality

Techniques for evaluating edge sharpness and durability. The role of inspection tools in edge quality assessment.To check edge quality, you can use several methods. One popular way is to look closely at the cutting edge with a microscope. This helps you see if it is sharp and free of damage. You can also feel the edge gently to test its sharpness. Another technique is using a tool like a hardness tester to see how strong the edge is.

Inspection tools are very important. They help check both the sharpness and durability of the cutting edge. Ensuring they are in good shape can greatly affect their performance.

How do you measure edge quality?

You can measure edge quality using these techniques:

- Microscopic inspection

- Touch feeling

- Hardness testing

Each method provides valuable information about the tool’s condition, helping to keep it sharp for longer.

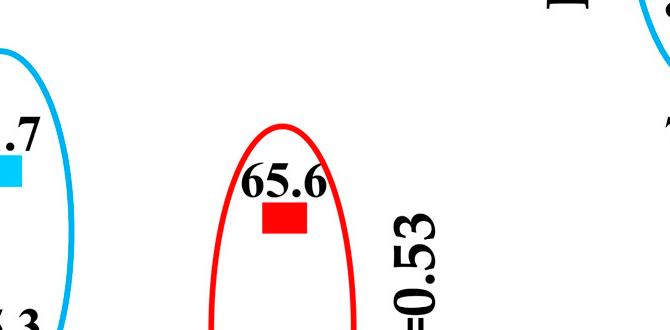

Impact of Edge Prep on Material Removal Rates

Correlation between edge preparation and machining efficiency. Case studies showcasing the impact of edge prep on productivity.Edge preparation can greatly affect how fast materials are removed during machining. A well-prepped edge cuts more efficiently, saving time and resources. Studies show that tools with proper edge prep can improve productivity by 20% or more. For example, one factory reported reduced cycle times, leading to higher output and profits.

- Better edge prep leads to faster cuts.

- Tools last longer with good edge prep.

- More productivity means more profit.

How does edge prep affect productivity?

Edge prep improves productivity by enhancing cutting efficiency. When tools are sharp and well-prepared, they can cut through materials quickly, which speeds up the work process overall.

Common Mistakes in Edge Preparation

Identifying frequent pitfalls in edge prepping. How to avoid these mistakes for optimal tool longevity.Edge preparation is like tuning a guitar; if you don’t do it right, you won’t get beautiful music. A common mistake is skipping the inspection of the cutting edge. This can lead to rough finishes and tool breakage. Another blunder is using dull tools. It’s tempting to keep going, but a sharp edge saves time and money. Always check your tools and make necessary adjustments. Avoid these pitfalls to keep your tools singing for longer!

| Common Mistakes | How to Avoid |

|---|---|

| Neglecting edge inspection | Regularly check cutter edges |

| Using dull tools | Replace or sharpen tools often |

| Skipping maintenance | Create a maintenance schedule |

Future Trends in Edge Preparation Technology

Emerging technologies shaping edge preparation practices. Potential innovations and their benefits for milling applications.New technologies are changing how we prepare milling cutter edges. Tools are becoming sharper and last longer. For instance, laser edge preparation can make cuts more precise. Advanced coatings help tools resist wear and tear. These innovations can lead to better results in milling. Here are some benefits:

- Increased tool durability.

- Improved cutting performance.

- Less downtime for replacements.

As we look ahead, exciting developments promise to make machining even better.

Why is edge preparation important?

Edge preparation helps tools cut smoothly and last longer. It reduces wear, leading to better performance and fewer tool changes. This makes work easier and more efficient.

Conclusion

In conclusion, proper edge preparation of milling cutters is crucial for tool longevity. Sharp, well-maintained edges cut better and last longer. Regular checks and simple sharpening can prevent wear and tear. You can improve your machining skills by learning more about edge prep techniques. Explore more resources to discover the best practices for keeping your tools sharp and efficient!FAQs

What Are The Primary Methods For Preparing The Cutting Edges Of Milling Cutters To Enhance Tool Longevity?To help milling cutters last longer, we can do a few things. First, we can sharpen the cutting edges so they stay sharp. Second, we can coat them with special materials to reduce wear and tear. Third, we should keep them clean to avoid dirt and dust. These steps help the cutters work better and last longer.

How Does Edge Preparation Influence The Performance And Wear Resistance Of Milling Cutters During Machining?Edge preparation means how we shape the sharp edge of a milling cutter. A well-prepared edge helps the cutter cut smoothly and quickly. This makes it last longer and resist wear better. If the edge is rough or not sharp enough, it can break or wear out faster. So, taking care of the edge helps the cutter work better and last longer.

What Role Do Different Sharpening Techniques Play In Extending The Lifespan Of Milling Cutter Edges?Different sharpening techniques help keep milling cutter edges sharp and ready to cut. When we sharpen them correctly, they last longer and work better. Some techniques make sure the edges are smooth, while others shape them in special ways. By using the right technique, you can help the cutters stay effective and save money over time. Taking care of them means you’ll have tools that work longer before needing to replace them.

How Can Improper Edge Preparation Negatively Affect The Machining Process And Tool Life Of Milling Cutters?If we don’t prepare the edges of cutting tools properly, they can break or wear out faster. This means we might have to stop working more often to replace them. Poor edges can also make it harder to cut materials, causing rough results. This can waste time and make us frustrated. Good edge preparation helps our tools last longer and work better.

What Materials And Coatings Are Most Effective For Extending The Life Of Milling Cutter Edges Through Proper Preparation?To make milling cutter edges last longer, we can use special materials and coatings. Carbide is a tough material that helps the cutter stay sharp. Coatings like titanium nitride (TiN) create a hard surface to resist wear. We should prepare the cutter edges carefully to ensure these materials work well. Taking good care of the tools helps them last much longer!