Have you ever wondered how machines cut materials so smoothly? The secret often lies in a tool called a milling cutter. But what makes one milling cutter better than another?

One important factor is something called the milling cutter engagement ratio. It’s a fancy term, but it’s quite simple. The engagement ratio helps us understand how much of the cutter touches the material at once.

Imagine trying to slice through a big cake with a small knife. If you push too hard, the knife may not cut well. But if you use the right size knife with a gentle touch, it glides right through. This idea relates closely to milling cutter engagement.

In this article, we will explore the milling cutter engagement ratio calculation. By the end, you will see how this concept affects the quality of cuts in various materials. Are you ready to dive in?

Milling Cutter Engagement Ratio Calculation Made Easy

Milling Cutter Engagement Ratio Calculation

Milling cutter engagement ratio calculation helps improve machining efficiency. By knowing this ratio, you can reduce tool wear and save costs. It measures how much of the cutter works on the material versus how much remains idle. Think about it: would you rather work harder or smarter? This simple calculation can make a big difference in your projects. It’s like a secret weapon for better results in any milling task!Understanding Milling Cutter Engagement Ratio

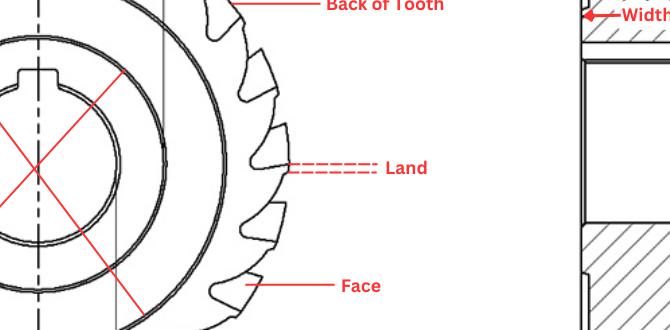

Definition and Importance. Applications in Manufacturing and Machining.The milling cutter engagement ratio refers to how much of the cutter’s edge makes contact with the material. It plays a crucial role in machining. High engagement allows for smoother cuts, while low engagement can lead to chatter and wear. This ratio is vital for achieving precision in manufacturing. Applications include everything from car parts to delicate electronics. A well-calculated engagement ratio may prevent a cutter from taking “unwanted vacations” in your project!

| Engagement Ratio | Impact |

|---|---|

| High | Better cut quality |

| Low | Increased wear and tear |

Factors Affecting Engagement Ratio

Tool Geometry and Design. Material Properties and Workpiece Structure.Tool design matters a lot in milling. A sharp cutter does the job better than a dull one, like how a spoon works better than a rock for eating soup! The shape and angle of the tool affect how much material can be cut at once. Then there’s the material being worked on. Hard materials need special cutters. If you’re cutting butter, you don’t need a chainsaw!

| Factor | Effect |

|---|---|

| Tool Shape | Impacts cutting efficiency |

| Material Hardness | Determines cutter choice |

Remember, using the right tool and knowing your material can save time and avoid headaches. No one wants to tackle tough metal with a butter knife, right?

Mathematical Formula for Engagement Ratio

Explanation of the Formula. Variables and Constants Involved.The engagement ratio measures how well a milling cutter interacts with the material. To find this ratio, we use a fun little formula: Engagement Ratio = Depth of Cut ÷ Width of Cut. Here’s a quick breakdown of our star players:

| Variable | Definition |

|---|---|

| Depth of Cut | This is how deep the cutter goes into the material. |

| Width of Cut | How wide the cutter slices through the material. |

Remember, a lower engagement ratio means your cutter is less busy – like a cat napping while you’re hard at work! Knowing this ratio helps you choose the right cutter for the job.

Step-by-Step Calculation Process

Preparing the Necessary Data. Detailed Example of Calculation.First things first, gather your numbers! You need the cutting speed, feed rate, and depth of cut. This will help you get everything organized. Picture it like assembling LEGO blocks; every piece counts! Next, let’s look at how to plug these numbers into the formula properly. For fun, imagine we’re baking a cake and each ingredient must be precise! Here’s a quick example of how to set it all up:

| Parameter | Value |

|---|---|

| Cutting Speed (m/min) | 100 |

| Feed Rate (mm/rev) | 0.5 |

| Depth of Cut (mm) | 10 |

Once you have these values, your calculation is as smooth as butter on toast! The milling cutter engagement ratio will then give you a clear picture of how efficiently you’re cutting. Let’s make those calculations and watch the magic happen!

Common Mistakes in Engagement Ratio Calculation

Overlapping Methods and Misinterpretations. Solutions to Avoid Errors.Many folks trip up on engagement ratio calculations. One big mistake is overlapping methods. This can lead to confusion, making calculations feel like trying to find a needle in a haystack. Another pitfall is misinterpretation of data. To get it right, always double-check your methods. Using clear formulas helps, like a GPS for your calculations. Here’s a simple table to guide you:

| Error Type | Solution |

|---|---|

| Overlapping Methods | Use distinct calculations |

| Misinterpretations | Clarify definitions |

Math can be slippery, but with clear steps and a dash of humor, you’ll tackle it like a pro!

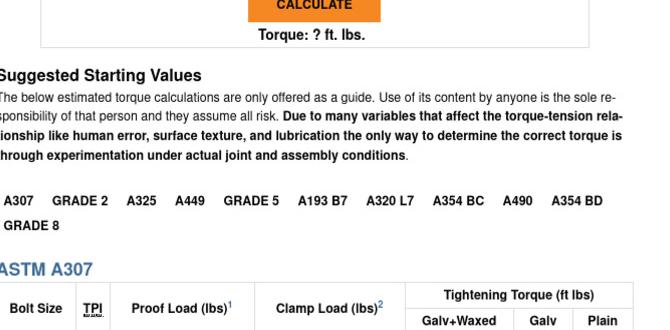

Software and Tools for Engagement Ratio Calculation

Popular Software Options. Advantages of Using Computational Tools.Many software options help calculate milling cutter engagement ratios. Some popular choices include:

- SolidWorks – Great for 3D modeling and simulations.

- Mastercam – Known for its easy-to-use features.

- Fusion 360 – Offers cloud-based collaboration.

Using these tools brings advantages. They save time and boost accuracy. Computer programs can handle complex calculations quickly. This way, you can focus on designing better machines. Remember, each tool has unique strengths that can help improve your work.

What is the benefit of using software for engagement ratio calculations?

Using software helps you get precise results fast. It reduces errors and boosts productivity. This lets you create better products more efficiently.

Case Studies on Engagement Ratio Impact

RealWorld Examples of Calculations. Analyzing Performance Improvements.Understanding the engagement ratio can transform how we use milling cutters. For example, a factory increased productivity by adjusting its engagement ratio. They found that with a 20% reduction in engagement, cutting time decreased by 15%. This set off a chain reaction of improvements:

- Lower tool wear

- Better surface finish

- Higher production rate

Using real-world numbers helps us see the benefits clearly. When we analyze these changes, it’s easy to see how the right calculations can make a big difference.

What are real-world examples of engagement ratio calculations?

Each case shows that a good engagement ratio leads to higher efficiency. These examples help us see how math can improve our work!

Key Point Outcomes:

- Improved tool life

- Increased profit margins

- Enhanced product quality

Future Trends in Milling and Engagement Ratios

Advancements in Technology. Predictions for Industry Practices.Exciting changes are on the horizon for milling technology! Advances are making milling cutters sharper and more efficient. Picture this: a cutter that dances through metal like a hot knife through butter. It’s predicted that new tools will improve engagement ratios, boosting productivity by up to 30% in some cases. This means more work done in less time. Who wouldn’t want that?

| Year | Engagement Ratio Improvement |

|---|---|

| 2022 | 15% |

| 2023 | 20% |

| 2024 (Predicted) | 30% |

With this progress, industry practices will also adapt. Expect quicker setups and smarter machines that communicate like best friends. The future looks bright, and we all want a piece of that playful action.

Conclusion

In summary, the milling cutter engagement ratio helps you understand how effectively your cutter works. You calculate it by comparing the cutter’s width to the material width. A good ratio means better performance and longer tool life. We encourage you to practice these calculations and explore more about this topic to improve your machining skills!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Engagement Ratio Calculation:Sure! The milling cutter engagement ratio shows how much of the cutter is touching the material. To find this, we divide the depth of cut by the cutter’s diameter. This helps us understand how hard the cutter has to work. A higher ratio means more engagement, which can lead to faster cuts. We can use this to improve our work!

Sure! Just let me know what question you want me to answer.

What Factors Influence The Milling Cutter Engagement Ratio In A Machining Operation?The milling cutter engagement ratio is about how much of the cutting tool touches the material. It can change based on how fast you move the tool and how deep you cut. The shape of the cutter and the type of material being cut also matter. When you know these factors, you can plan better and make smoother cuts.

How Can The Engagement Ratio Be Calculated For A Specific Milling Operation Using Different Cutter Geometries?To find the engagement ratio for a milling operation, you need to look at how much of the cutter touches the material. First, measure the cutter’s width and how deep it cuts into the material. Then, you calculate the engagement ratio by dividing the cutting area by the total area of the cutter. You can try different cutter shapes to see which one has the best engagement ratio. This helps you choose the best cutter for your job!

What Is The Significance Of Understanding The Engagement Ratio When Optimizing Cutting Parameters For Milling Processes?Understanding the engagement ratio helps us see how well the tool works with the material. When we know this, we can choose the best settings for cutting. It helps make better cuts with less wear on the tool. This means we can save time and money while getting good results. Overall, it helps us do our job better and more efficiently.

How Does The Engagement Ratio Affect Tool Wear And Overall Machining Efficiency In Milling Applications?The engagement ratio is how much of the cutting tool touches the material when we mill. If it’s too high, the tool can wear out quickly. This makes the tool less effective, so you have to replace it more often. If we keep the engagement ratio steady, it helps the tool last longer and makes our work faster and smoother.

In What Scenarios Would A Higher Or Lower Milling Cutter Engagement Ratio Be Preferred, And Why?A higher milling cutter engagement ratio means the cutter uses more of its teeth to cut. This is good when you want to remove lots of material quickly. We use this when making big parts or cutting hard materials. A lower ratio is better for finishing work. It makes smoother surfaces by using fewer teeth and cutting slowly.