Milling cutters are vital tools in machining. They create shapes and sizes in various materials. Have you ever wondered how they cut so smoothly? The secret lies in the flute geometry.

The flute design affects how chips flow away from the cutter. When the chips flow correctly, the milling process works better. Imagine trying to drink a thick shake through a tiny straw. It’s tough! The same goes for chip removal in milling.

Did you know that different flute shapes can change the cutting speed? Some flutes move chips away quickly while others hold on to them tightly. A perfect balance can improve the quality of your work.

In this article, we will explore milling cutter flute geometry and its impact on chip flow. Understanding this can help you make better choices while milling. Ready to find out more?

Milling Cutter Flute Geometry For Chip Flow Explained

Milling Cutter Flute Geometry for Chip Flow

Understanding milling cutter flute geometry is key for efficient chip flow. Flutes help remove chips by creating space between the cutting edges. Have you ever wondered why some cutters work better than others? The angle and depth of the flutes affect performance and the quality of the finished product. A well-designed flute can minimize clogging and improve speed. Choosing the right geometry can make a big difference in your milling projects!Understanding Milling Cutter Flute Geometry

Definition and purpose of flute geometry in milling cutters. Different types of flutes and their unique characteristics.Milling cutters have special shapes called flutes. Flute geometry helps remove chips while cutting. This makes the job smoother and faster. There are different types of flutes that work in unique ways:

- Straight Flutes: Great for soft materials; they cut straight and fast.

- Spiral Flutes: They twist! They pull chips away and help with smooth cutting.

- Ball Nose Flutes: Ideal for curved surfaces, giving a nice finish.

Knowing these types helps you choose the right cutter for your project!

What is flute geometry in milling cutters?

Flute geometry is the shape and design of the grooves on a milling cutter. It helps manage chip flow efficiently.

The Role of Flute Design in Chip Removal

How flute shape influences chip flow and evacuation. Effects of flute design on machining efficiency and surface finish.The shape of the flute plays a big role in how chips flow during cutting. A well-designed flute helps chips escape easily. When chips are removed efficiently, machining becomes faster. This not only improves productivity but also leads to a better surface finish. Flute design affects the overall cutting process, making it smoother and cleaner.

- Deep flutes help in quick chip removal.

- Shallow flutes can cause clogging.

- Correct flute angles enhance chip flow.

How does flute design affect machining efficiency?

A good flute design can increase machining efficiency by allowing chips to exit easily. This creates less heat and wear on tools. Better chip flow means faster work and cleaner cuts.

Factors Affecting Chip Flow Performance

Impact of flute width and depth on chip flow. Relationship between flute angle and chip removal rates.Several factors influence how well chips flow during milling. One key factor is the flute width and depth. Wider flutes help chips move out easily, while deeper flutes create space for more chips. Angle plays a role too. A good flute angle boosts chip removal rates. If the angle is too steep or too shallow, it can slow down the process.

How does flute width and angle affect chip flow?

Wider flutes and correct angles help chips escape quickly. This leads to faster and cleaner cutting.

Key Points:

- Wider flute width aids easy chip removal.

- Deeper flutes allow more chips to fit.

- Proper flute angle improves chip flow.

Material Considerations for Flute Design

Common materials used for milling cutters and their influence on flute geometry. How material properties affect chip flow and cutter performance.Choosing the right material for milling cutters is like picking the best ice cream flavor. Each one has its perks! Common choices include high-speed steel (HSS), carbide, and cermet. These materials can change how flutes are shaped. For example, carbide is tough and holds its shape well, making it ideal for long-lasting cuts. However, this toughness can also affect how chips flow away from the cutter. Better chip flow means fewer jams and a smoother process. Here’s a quick look:

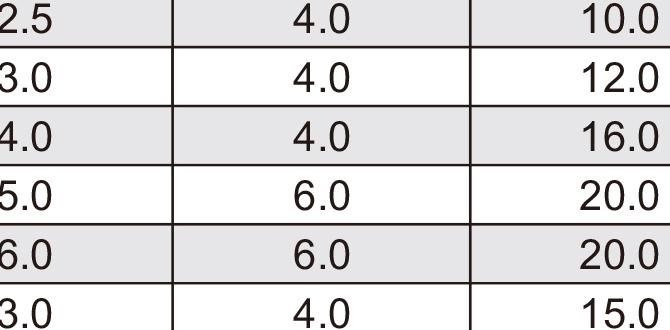

| Material | Characteristics | Effect on Chip Flow |

|---|---|---|

| High-Speed Steel (HSS) | Flexible, good for general use | Average chip flow; can clog |

| Carbide | Very strong, lasts longer | Great chip flow; less clogging |

| Cermet | Resistant to wear, less brittle | Good chip flow; efficient |

So, remember, the right material means better chip management and performance — like having a well-trained chef in the kitchen!

Advanced Flute Geometries and Innovations

Emerging trends in milling cutter flute design for enhanced chip flow. Case studies of innovative flute geometries and their benefits.New designs for milling cutter flutes are changing the way chips flow. These advanced geometries help to improve cutting efficiency. Several case studies show how new shapes result in faster production and less wear on tools.

- Better chip removal reduces clogging.

- Innovative angles minimize friction.

- Unique flute shapes enhance cooling.

The future looks bright for milling cutters. With these developments, industries can expect less downtime and more precise work. This is an exciting time for cutting technology!

How do advanced flute designs improve chip flow?

Advanced flute designs boost chip flow by creating space for easier removal and reducing friction. These features allow machines to run smoother and faster, enhancing overall performance.

Additional Benefits of New Flute Designs

- Increased tool life.

- Higher machining speeds.

- Less heat production.

Best Practices for Selecting Milling Cutters

Guidelines for choosing the right milling cutter based on material and application. Importance of aligning flute geometry with machining requirements for optimal performance.Choosing the right milling cutter can be tricky, like picking the right ice cream flavor! First, consider the material you’re working with. Different materials need different cutters, just like chocolate is great for some desserts but not for all. Aligning the cutter’s flute geometry with your machining needs is key for smooth chip flow and performance. Remember, a cutter that works well for aluminum might not perform as well on steel. This is how you keep everything running smoothly!

| Material | Recommended Cutter Type |

|---|---|

| Aluminum | High-speed steel |

| Steel | Carbide |

| Plastic | Specialty cutters |

Common Issues with Chip Flow and Flute Geometry

Identifying problems associated with poor chip removal. Troubleshooting techniques for optimizing flute design and performance.Chip removal can be tricky. Poor chip flow leads to problems like clogs and overheating. This can ruin both your tools and your day! To fix this, check the flute geometry. Wider flutes usually allow better chip flow. Also, adjusting the cutting speed can help. If the chips aren’t clearing, it’s time to rethink that design!

| Problem | Solution |

|---|---|

| Poor Chip Flow | Wider Flute Design |

| Overheating | Adjust Cutting Speed |

| Clogs | Optimize Flute Angle |

Remember, the right flute geometry can make you a chip-flow hero!

Conclusion

In conclusion, milling cutter flute geometry greatly affects chip flow. A well-designed flute helps chips move more efficiently, preventing clogging. This keeps your work efficient and tools in good shape. Remember, understanding these concepts can improve your projects. Explore further resources to dive deeper into milling techniques. Happy milling, and keep experimenting to see what works best for you!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Flute Geometry For Chip Flow:Sure! Here are five questions you can think about when learning about milling cutter flute geometry for chip flow: 1. **What is a flute in a milling cutter?** A flute is the groove or channel on a cutter that helps chips flow out while cutting. 2. **Why is chip flow important?** Good chip flow keeps the cutter cool and helps it work better. 3. **How does flute shape affect cutting?** The shape of the flute can change how easily chips move away from the cutter. 4. **What happens if chips don’t flow well?** If chips pile up, they can cause the cutter to break or make poor cuts. 5. **Can you change the flute design?** Yes! Different designs help with different materials, making cutting easier and better.

Sure! Please share the question you want me to answer, and I’ll be happy to help!

How Does The Design Of Flute Geometry Influence Chip Evacuation During The Milling Process?The shape of the flutes on a milling tool helps move tiny pieces, or chips, away while cutting. If the flutes are deep and wide, they can carry more chips faster. This keeps the cutting area clean, helping the tool work better and last longer. So, good flute design helps the tool run smoothly and makes for a better job!

What Are The Effects Of Different Flute Shapes (E.G., Helical, Straight, Or Variable Pitch) On The Performance Of A Milling Cutter In Terms Of Chip Flow?Flute shapes on a milling cutter help control how chips flow away while cutting. Helical flutes twist and help chips move out easily. Straight flutes allow chips to come out but may pack up sometimes. Variable pitch flutes mix both types, improving chip flow by preventing clogs. Overall, the shape you choose can make cutting smoother and faster.

How Does The Depth And Width Of The Flutes Affect The Cooling And Lubrication During Machining Operations?The depth and width of the flutes in a cutting tool help with cooling and lubrication. Deep and wide flutes let more cooling liquid flow. This keeps the tool and metal cool. It also helps wash away tiny metal bits. So, better flutes mean smoother and cooler cutting!

What Role Does The Angle Of The Flute Play In Minimizing Chip Recutting And Improving Surface Finish During Milling?The angle of the flute on a milling tool helps in two main ways. First, it lets chips, or tiny bits of metal, flow away easily. This means less chance for the chips to get cut again, which keeps the work smooth. Second, the right angle helps make a better surface finish on your project, making it look nicer and feel smoother. So, choosing the right angle really helps in getting good results when you are milling!

How Can Advancements In Computational Fluid Dynamics (Cfd) Be Utilized To Optimize Milling Cutter Flute Designs For Better Chip Flow Management?We can use advancements in Computational Fluid Dynamics (CFD) to study how air and chips move around milling cutters. By simulating the flow, we can see which flute shapes work best. These shapes can help chips move away faster. This means less clogging and better cutting! In short, CFD helps us design better tools for easier work.